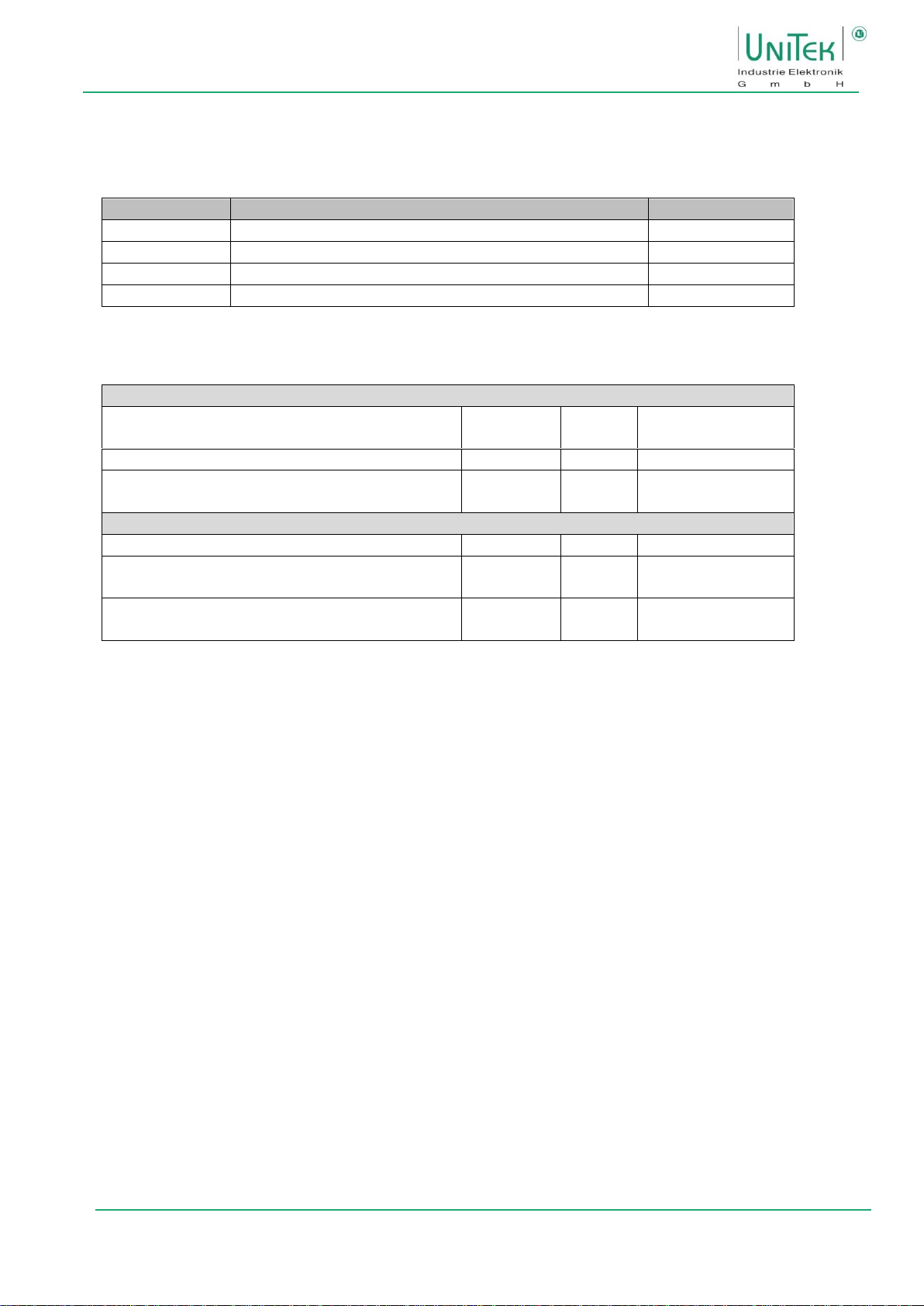

Basic informationen

BAMOCAR-PG-D3-700/400-400

Contents

1Basic informationen...................................................................................................................3

1.1 History .......................................................................................................................................... 3

1.2 Further UNITEK products.............................................................................................................. 3

1.3 Engineering instructions (MANUAL)............................................................................................. 3

1.4 Validity.......................................................................................................................................... 4

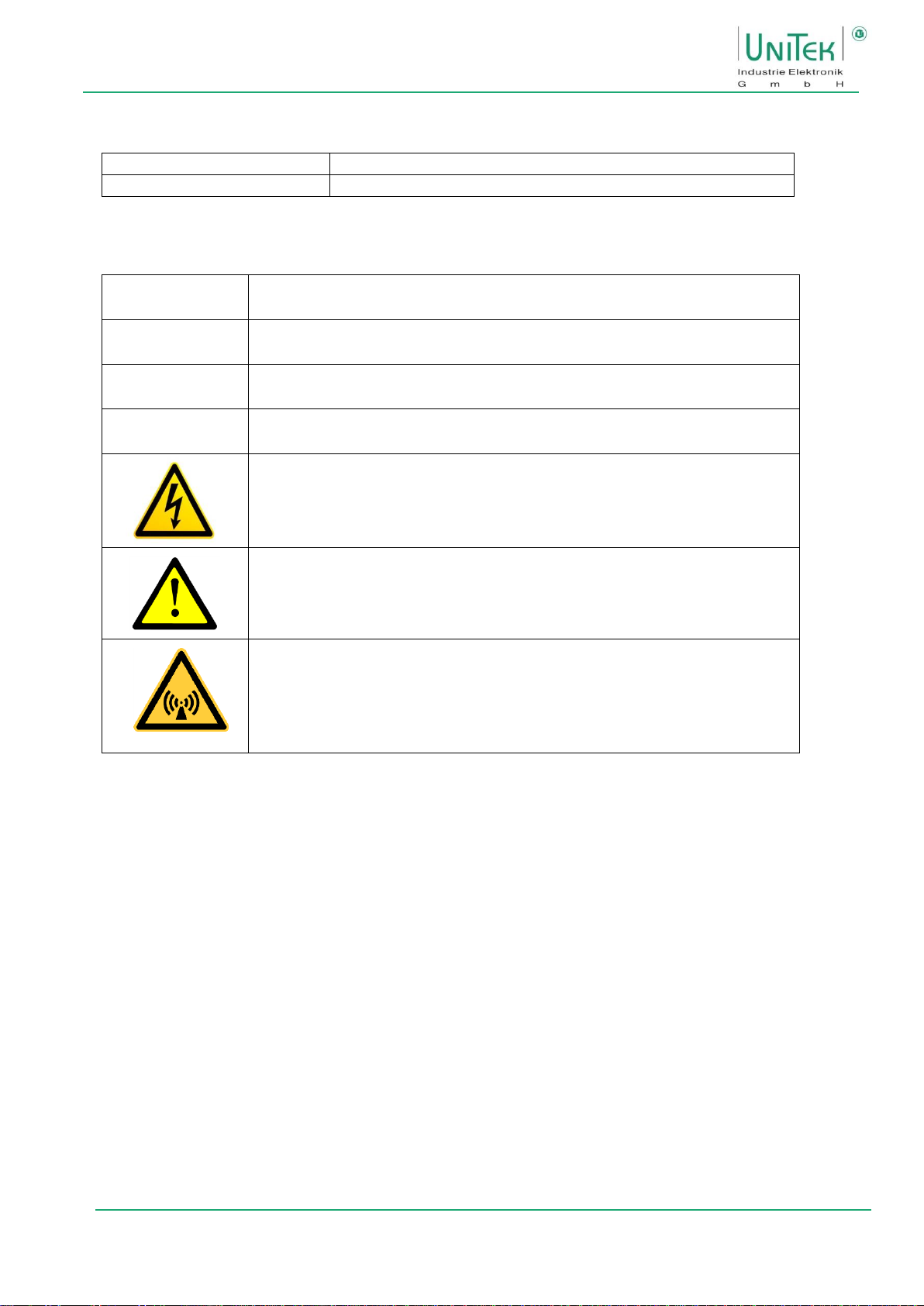

1.5 Designations and symbols............................................................................................................ 4

1.6 General product information ....................................................................................................... 5

1.7 Applications/build/features ......................................................................................................... 6

1.8 Safety regulations......................................................................................................................... 8

1.9 Commissioning ........................................................................................................................... 10

1.10 Safety advices............................................................................................................................. 11

1.11 Intended applications................................................................................................................. 12

1.12 Regulations and guidelines......................................................................................................... 13

1.13 Risks............................................................................................................................................ 14

1.14 Technical data ............................................................................................................................ 15

2Mechanical installation ............................................................................................................ 18

2.1 Important notes ......................................................................................................................... 18

2.2 Dimensions BAMOCAR-PG-D3-700/400-400 ............................................................................. 19

2.3 Mounting onto mounting rails ................................................................................................... 21

2.4 Mounting onto a mounting surface ........................................................................................... 21

3Electrical installation................................................................................................................ 22

3.1 Important advices....................................................................................................................... 22

3.2 Circuit diagram ........................................................................................................................... 23

3.3 Connection diagram ................................................................................................................... 25

3.4 EMC advice................................................................................................................................. 26

3.5 Connectors ................................................................................................................................. 28

3.6 Auxiliary voltage connection...................................................................................................... 30

3.7 Power connections..................................................................................................................... 31

3.8 Battery connection..................................................................................................................... 32

3.9 Motor power connection ........................................................................................................... 33

4Control connections................................................................................................................. 34

4.1 Digital inputs............................................................................................................................... 34

4.2 Safety input RFE (Rotating field enable) / Stop class 0 .............................................................. 35

4.3 Digital outputs (open emitter) ................................................................................................... 36

4.4 Signal contact Ready (Solid State Relais) / Ready BTB / RDY .................................................... 37

4.5 Analog input +/- 10 V ................................................................................................................. 38

4.6 Analog output –not available .................................................................................................... 38