Classic C1 230/180 - 4 (f)

4

Thyristor Drive

- for inductive and ohmic consumer loads’

Applications

- speed control of dc motors

- 1-quadrant operation, driving

- power: up to 720W

- tacho control

- armature voltage control with IxR compensation

- torque control

- cascade control speed/current

- rectangular current/speed characteristic curve

- switch on and switch off logic

- mains connection can directly be switched

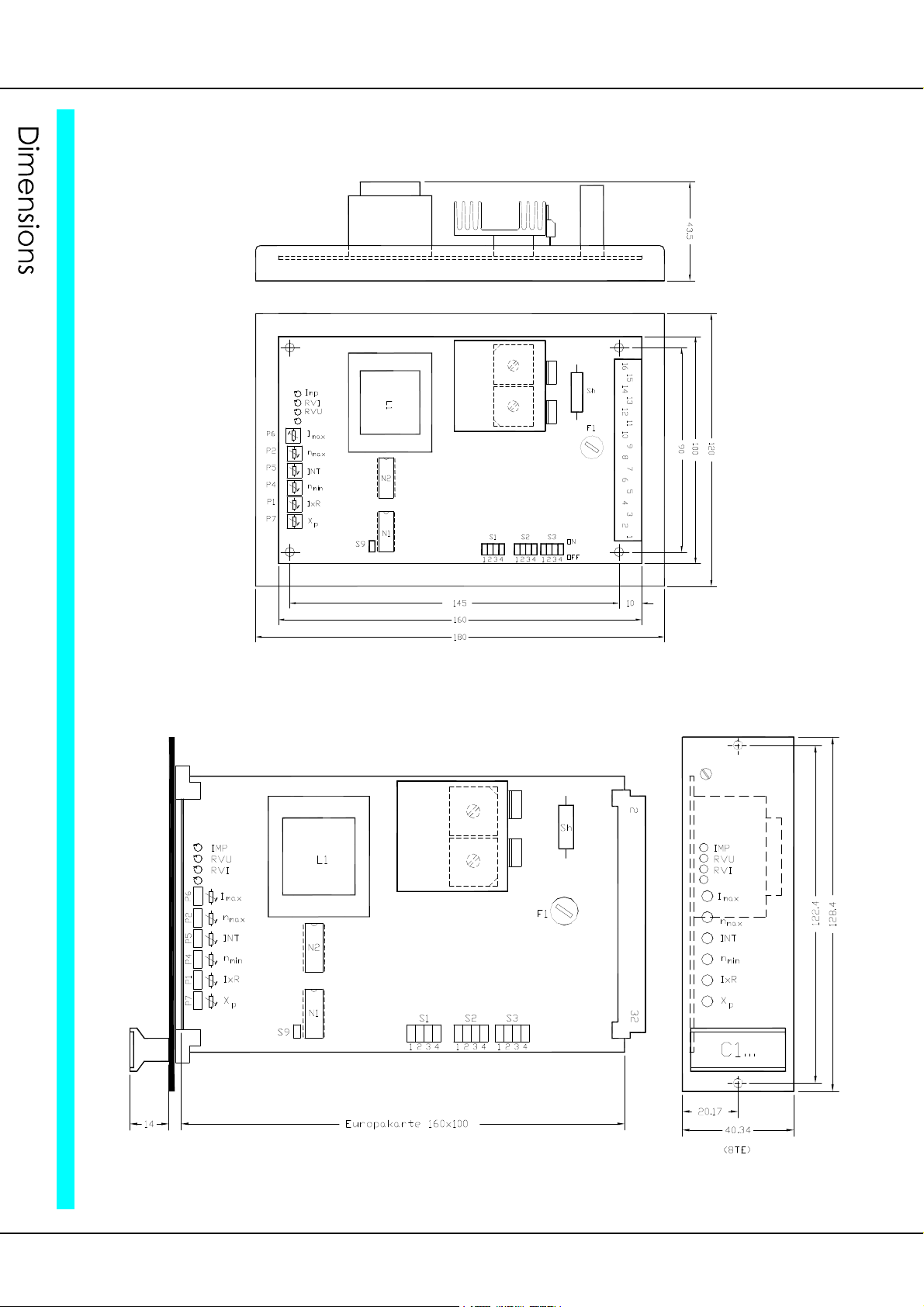

Compact single-board device

- European format

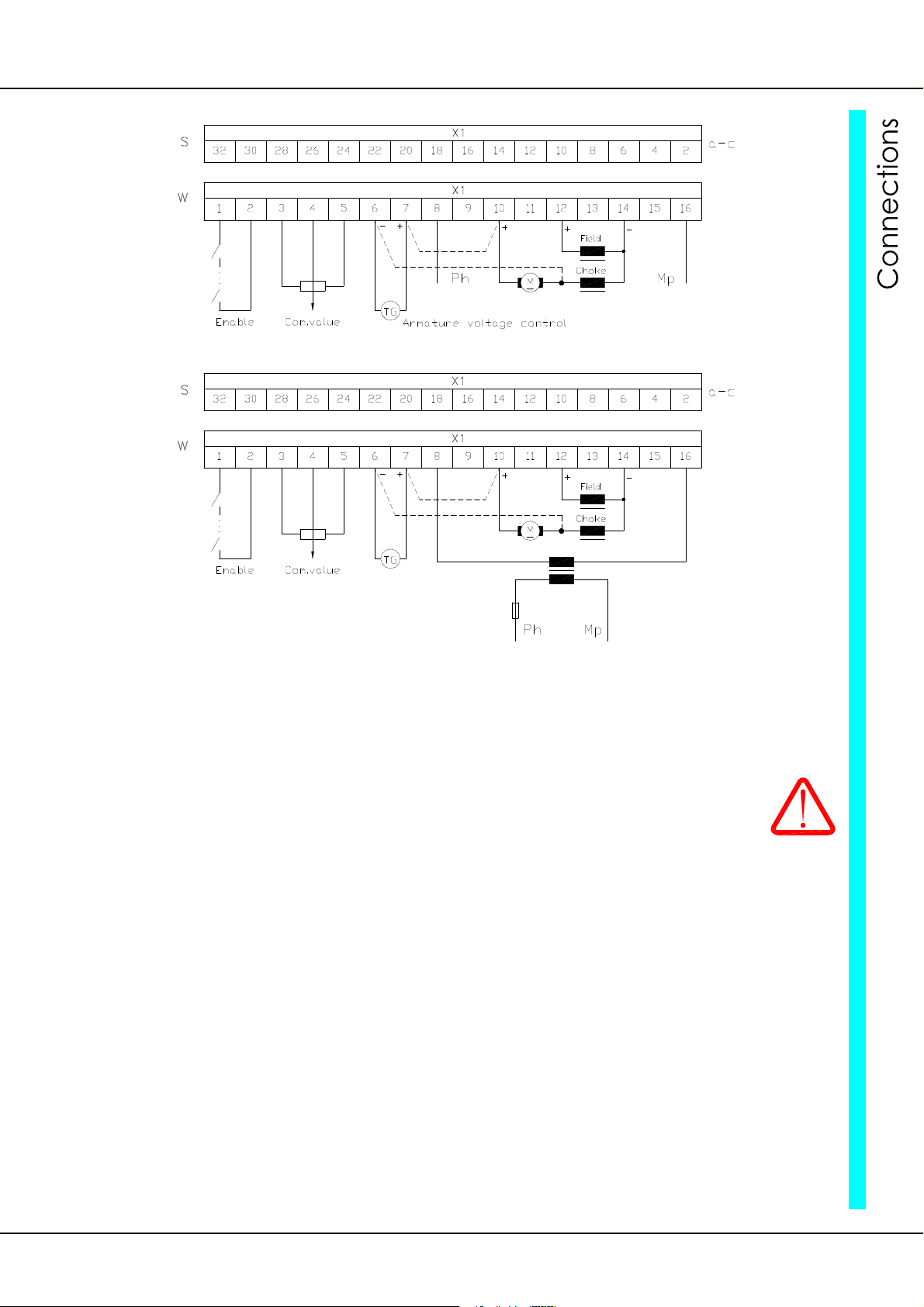

- pluggable terminal connection (-W)

- C1: galvanic connection

- C1-4f: galvanic isolation of the control and the power section

- fully insulated power semi-conductor

- field rectifier

Note for C1 devices:

Direct mains connection

- zero connection >> on thyristor negative electrode potential

- all control connections >> on mains potential

- switches and poti >> isolation voltage > 1500V

Connection via an isolating transformer

- zero connection >> with potential isolation

- control connections >> to be earthed and shielded

Note for C1-4f devices:

Tacho control

- device >> with potential isolation

Armature voltage control

- control unit >> with a high impedance mains connection

- zero connection (terminal no. 5) must not be earthed

Build

- switch cabinet mounting according to the VDE, DIN and EU regulations

- standard control electronics REG

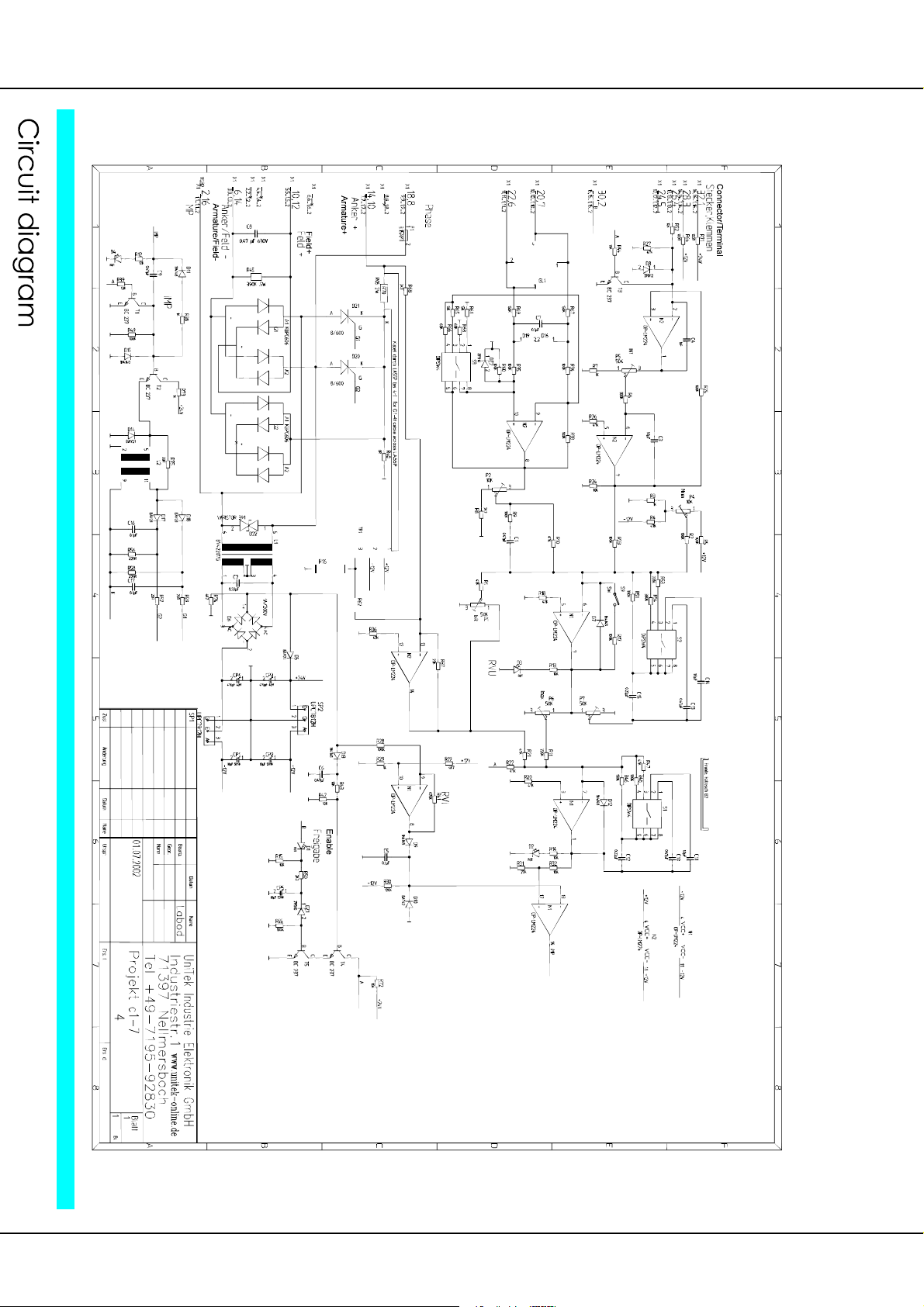

- intrinsically safe power section with current control loop

- optional units

Galvanic isolation between

- the power section and the housing

- the power section and the control electronics

The distance of air gaps and leakage paths adhere to the VDE standards (>8mm).

Components

- fully insulated thyristor modules, comfortably over-dimensioned

- only components customary in trade and industrially standardised are used

- high-quality bases for the IC with external connections

- LED displays

- DIP switches for the P-I adjustment of the current control loop

- precision potentiometers for fine adjustments

- plug-in jumpers for the system set-up