UT9930

2

Warning -Beware of materials after cutting.

Theymay behot and/orsharp whenhandled.

Recoilless Air Saw

Installation

The UT9930 Recoilless Air Saw is designed to operate with 90

PSIG. Lower pressure (below 90 PSIG) will reduce perfor-

mance of the tool while higher air pressure (over 90 PSIG)

raises the performance of the tool beyond its rated capacity and

could cause serious damage to tool and operator.

Always use clean dry air. Excessive moisture and dirt will

greatly reduce the life of any air tool. We recommend the

installation of an in-line filter-regulator-lubricator as close to the

tool as possible.

A 1/4" air hose is required up to a length of 8 ft. If more length is

required, a 3/8" air hose should be connected to the 1/4" hose

to ensure the tool has the necessary air supply. Be sure all

hoses and fitting are the correct size and tightly secured.

Lubrication

1. An automatic in-line filter-regulator-lubricator is recom-

mended to increase tool life and keeps the tool operating

properly. The in-line lubricator should be regularly

checked and filled with Marvel air tool oil or equivalent.

Proper adjustment of the in-line lubricator is performed by

placing a sheet of paper next to the tool exhaust ports and

holding the throttle open approximately 30 seconds. (The

lubricator is properly set when a light stain of oil collects on

the paper). Excessive amounts of oil should be avoided as

it will decrease tool performance.

2. In the event that it becomes necessary to store the tool for

an extended period of time (overnight, weekend, etc.), it

should receive a generous amount of lubrication at that

time. The tool should be run for approximately 30 seconds

to ensure oil has been evenly distributed throughout the

tool. The tool should be stored in a clean and dry environ-

ment.

3. Recommended lubricants:

Use Marvel Air Tool Oil or any other high grade turbine oil

containing moisture absorbents, rust inhibitors, metal

wetting agents and an EP (extreme pressure) additive.

Use care during use

Refer to blade manufacturer's specifications on "teeth per inch"

configuration. If not available, please refer to general blade

matching chart in this manual. Check that blade is secure,

lubricated, and does not have bent or missing teeth. Guide tool

through cut. Do not use excessive force while cutting. Opera-

tors may have to acquaint themselves with the unique operat-

ing characteristics of this tool.

Installing & Changing Saw Blades

Before the tool is connected to the air supply, clear the air hose

of accumulated dust and moisture. Before removing a tool for

service or changing accessories, make sure the air line is shut-

off and drained of air. This will prevent the tool from operating if

the throttle is accidently engaged.

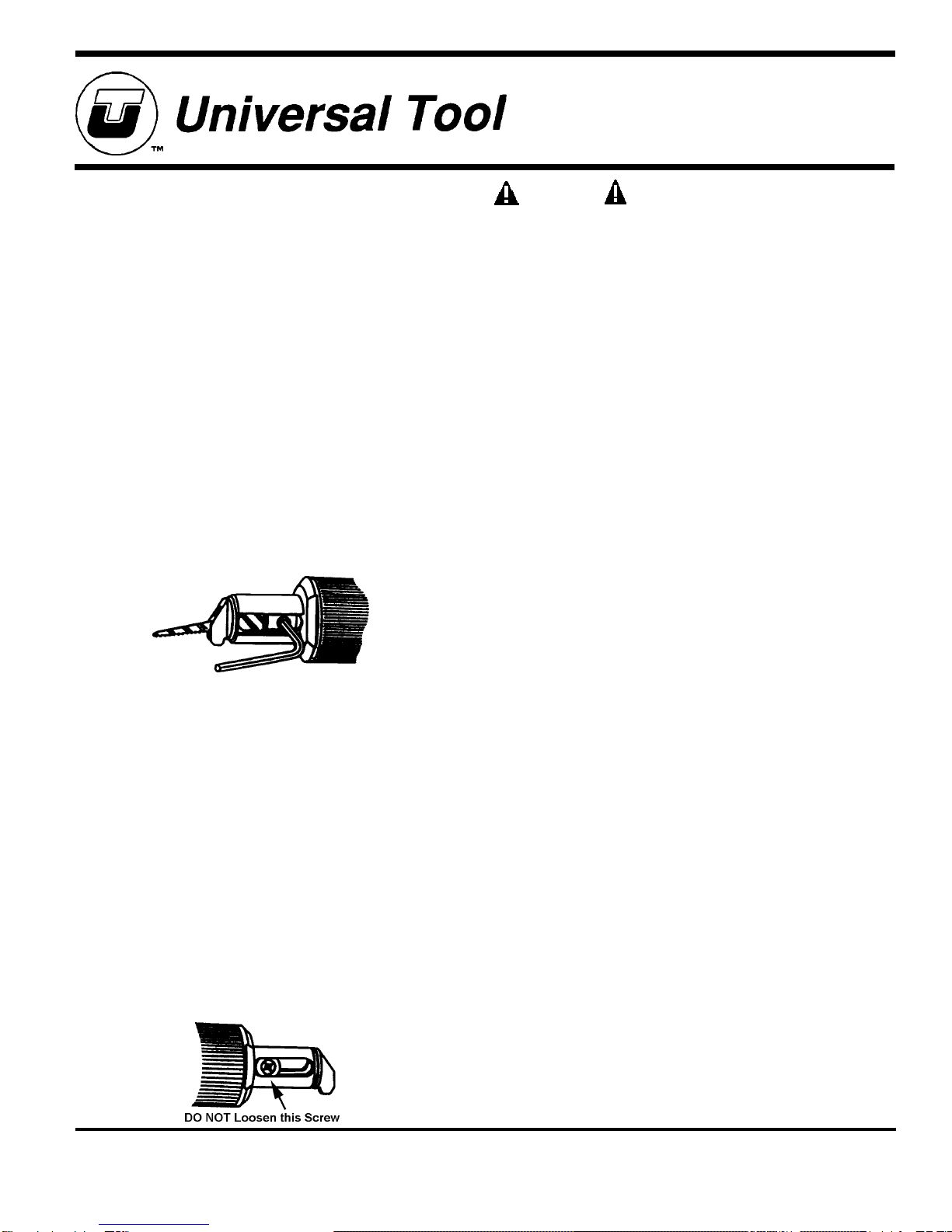

1. Twist front cover (Ref. No. 5) to expose the front left side of

tool (See Fig. 1) and loosen blade lock screw (Ref. No. 4)

with a standard 1/8" hex wrench.

2. Slide the new saw blade through the front and into the

piston extension (Ref. No. 7). Tilt blade down and retighten

the blade lock screw. DO NOT OVERTIGHTEN.

NOTE: Lock screw has special threads matched with piston

extension assembly. If screw is lost, replace only with original

parts to ensure safety and proper performance.

3. Ensure that the blade teeth are pointed down. Twist front

cover down to protect opening.

4. Lubricate tool through inlet with air tool oil and run in a

protected area to check operation. Use only new, straight,

and properly sized blades.

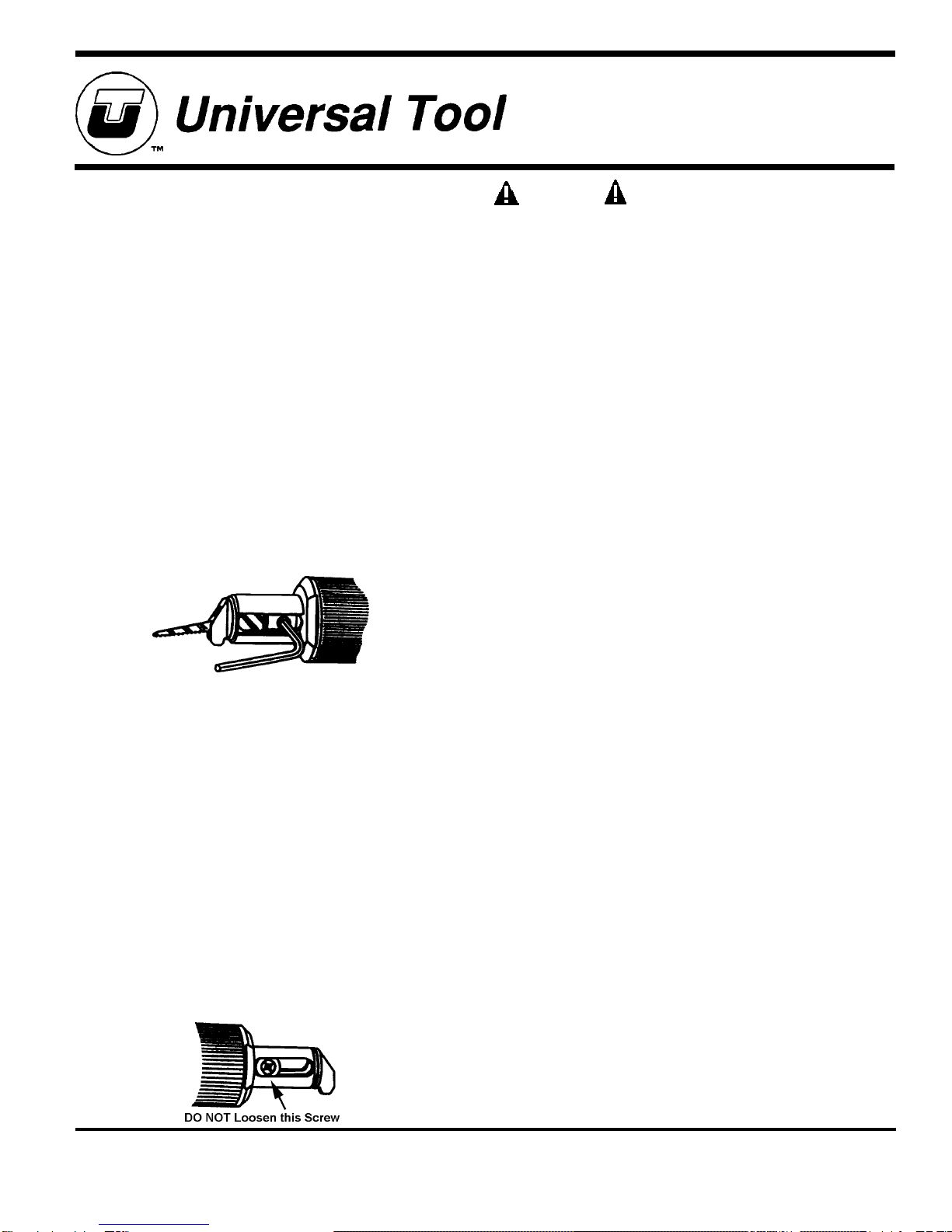

NOTE: DO NOT LOOSEN OR REMOVE PHILLIPS HEAD

SCREW ON OTHER SIDE OF TOOL! (See Figure 2) Use

strong Loctite (No. 270) to reset this screw if loosened.

Figure 1

Figure 2

Operation

This saw operates slightly different than traditional pneumatic

saws. Metal thickness should be 16 gauge or thinner, although

this saw will cut up to 3/8" threaded rod. Secure material to be

cut with a vise of other suitable clamps. High alloy steel may

need lubrication while cutting to improve performance. Keep

front of tool against work while cutting and guide tool through

work. There are no benefits gained by using excessive force

while cutting. The 360° lever handle will lock in place once

throttle is depressed.