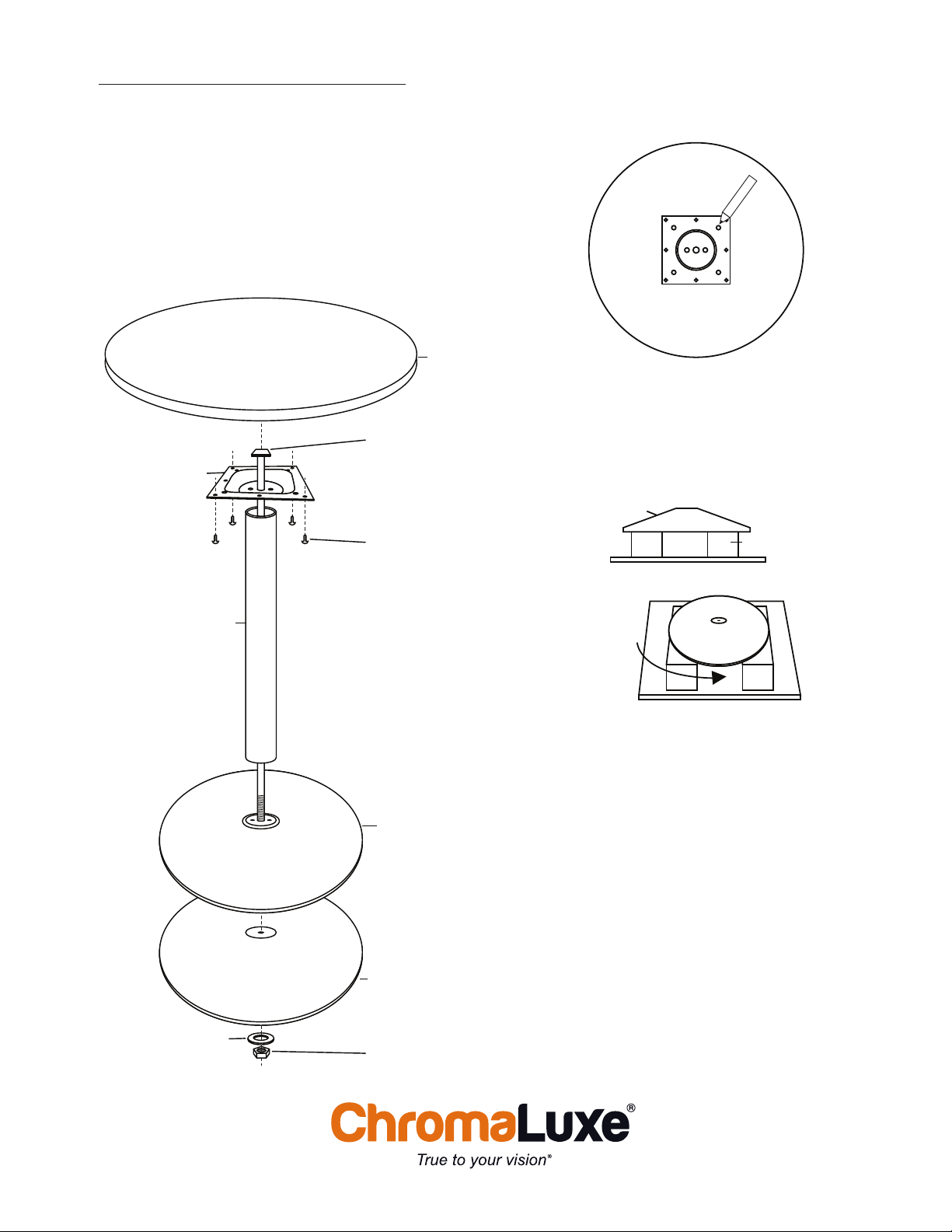

EXPLODED VIEW

B-SPIDER

A-THREADED ROD

H-TABLE TOP

D-TABLE BASE

COVER

C- COLUMN

E-TABLE BASE

(HEAVY)

F-WASHER G- HEX NUT

I-SCREWS

Center B-Spider on back of H-Table Top.

Mark and drill pilot holes you are

going to use to secure base

assembly to Table Top.

BACK OF TABLE TOP

1

Side View

ACCESS BLOCKS

TABLE BASE

3/4 View

ACCESS!

2

Set up access blocks (such as 4x4”s)

on your work surface so you can access

boom of E-Table Base.

Alternavely, you can work upside-down

to assemble base components.

3

Place square end of A-Threaded Rod in

spider. Place components onto Threaded

Rod shown in Exploded View.

B-Spider C-Column D-Table base cover

4

Insert threaded end of A-Threaded Rod

into E-Table Base. Underneath Table

Base, place F-Washer onto Threaded Rod.

Tighten assembly with G-Hex Nut with a

wrench.

5

Aligning with previously-marked pilot

holes, place H-Table Top onto base

assembly and install I-Screws to aach

Table Top to base assembly.

ChromaLuxe® is a registered trademark of Universal Woods, Inc. ©2015

MATERIALS NEEDED (for assembly)

• Sublimated ChromaLuxe table top

• Table base (from tablebases.com)

• Drill / Two 4x4 access blocks / Wrench

• One washer / One hex nut / Four screws

EXPLODED VIEW

B-SPIDER

A-THREADED ROD

H-TABLE TOP

D-TABLE BASE

COVER

C- COLUMN

E-TABLE BASE

(HEAVY)

F-WASHER G- HEX NUT

I-SCREWS

Center B-Spider on back of H-Table Top.

Mark and drill pilot holes you are

going to use to secure base

assembly to Table Top.

BACK OF TABLE TOP

1

Side View

ACCESS BLOCKS

TABLE BASE

3/4 View

ACCESS!

2

Set up access blocks (such as 4x4”s)

on your work surface so you can access

boom of E-Table Base.

Alternavely, you can work upside-down

to assemble base components.

3

Place square end of A-Threaded Rod in

spider. Place components onto Threaded

Rod shown in Exploded View.

B-Spider C-Column D-Table base cover

4

Insert threaded end of A-Threaded Rod

into E-Table Base. Underneath Table

Base, place F-Washer onto Threaded Rod.

Tighten assembly with G-Hex Nut with a

wrench.

5

Aligning with previously-marked pilot

holes, place H-Table Top onto base

assembly and install I-Screws to aach

Table Top to base assembly.