Page 6 of 26

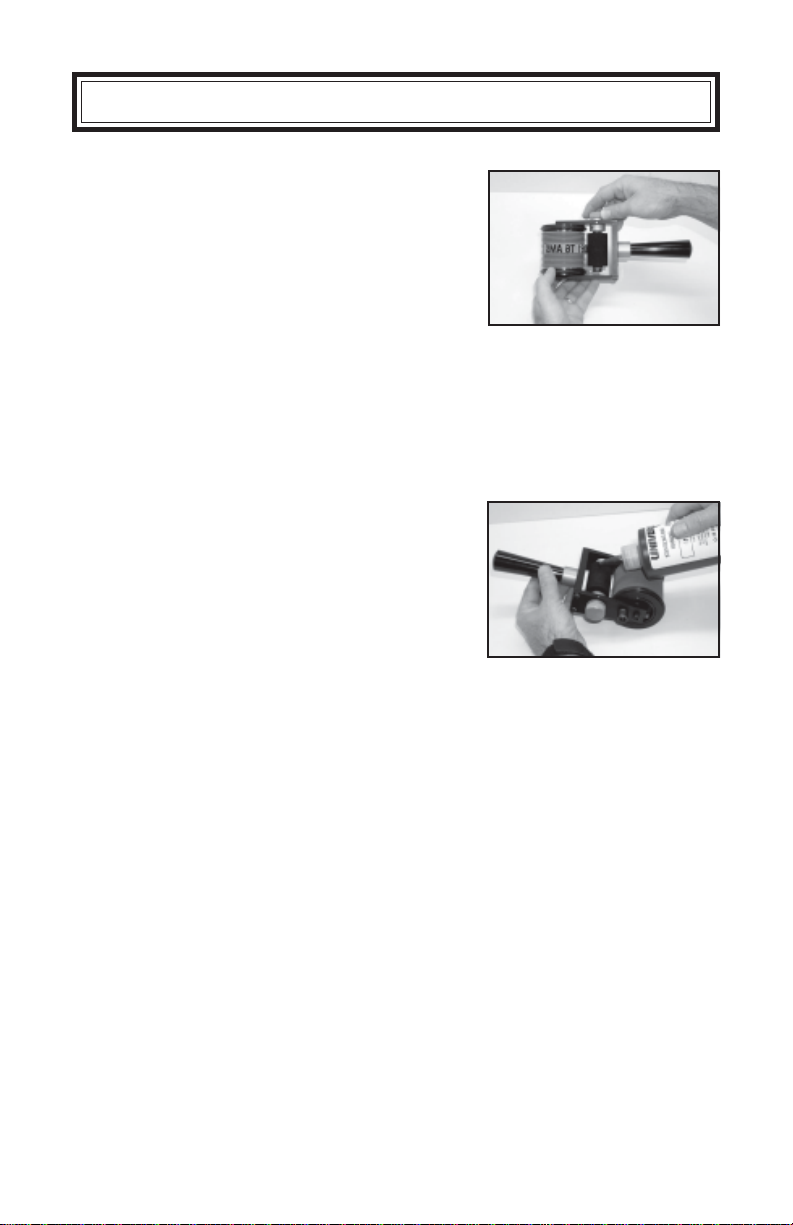

MICROCELL ROLLS: The standard ink rolls shipped with Universal Hand Print-

ers are made from reticulated urethane foam. This material is one of the most

durable ink roll materials available and with proper care should last in excess of

one year before replacement becomes necessary. Microcell rolls should be inked

with Universal No. 1150 porous coder ink only. It is extremely important to fol-

low the inking instructions or roll performance will be adversely affected.

INK ROLLS & INKS

SPECIFICATIONS

XF NEOPRENE ROLLS: Universal’s XF Neoprene Ink Rolls are made from an

extra firm density neoprene material. While not quite as durable as Microcell, the

extremely fine cell structure of these rolls provides exceptionally good print quality,

particularly when using small character printing dies. Due to their greater ability to

compensate for slight die thickness variations, these rolls are also recommended

to correct print quality problems when multiple lines of text are required.

Although these Hand Printers are not designed for production use with alcohol

base marking inks, the XF Neoprene Ink Rolls are compatible with a variety of

alcohol base inks. For limited use applications, slow drying alcohol base inks can

be used on the XF Neoprene ink rolls for marking on Non-Porous surfaces such as

metal,plastic,glass, etc. Pleasenote that thealcohol innon-porous inkswill evapo-

rate rapidly leaving the rolls dry and hard in a relatively short period of time. After

use with alcohol base inks, the rolls should be immediately removed from the coder

and stored in an air tight container.

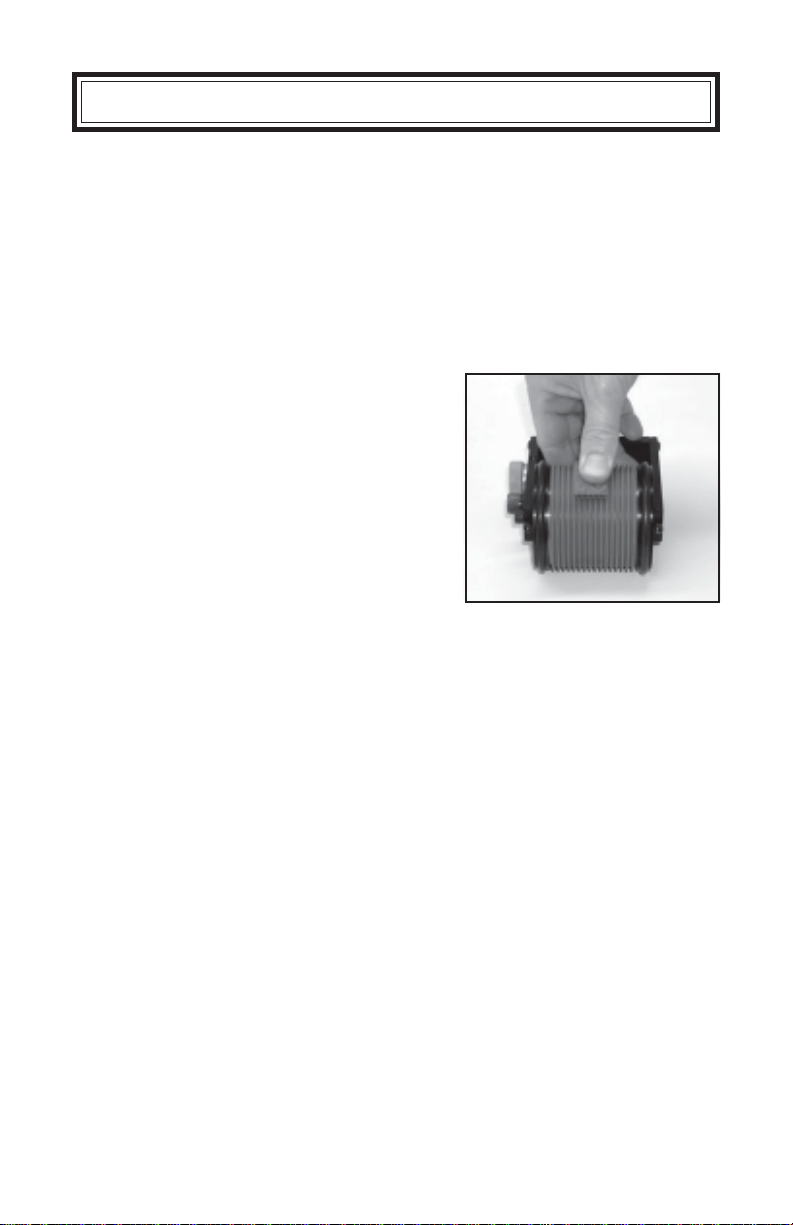

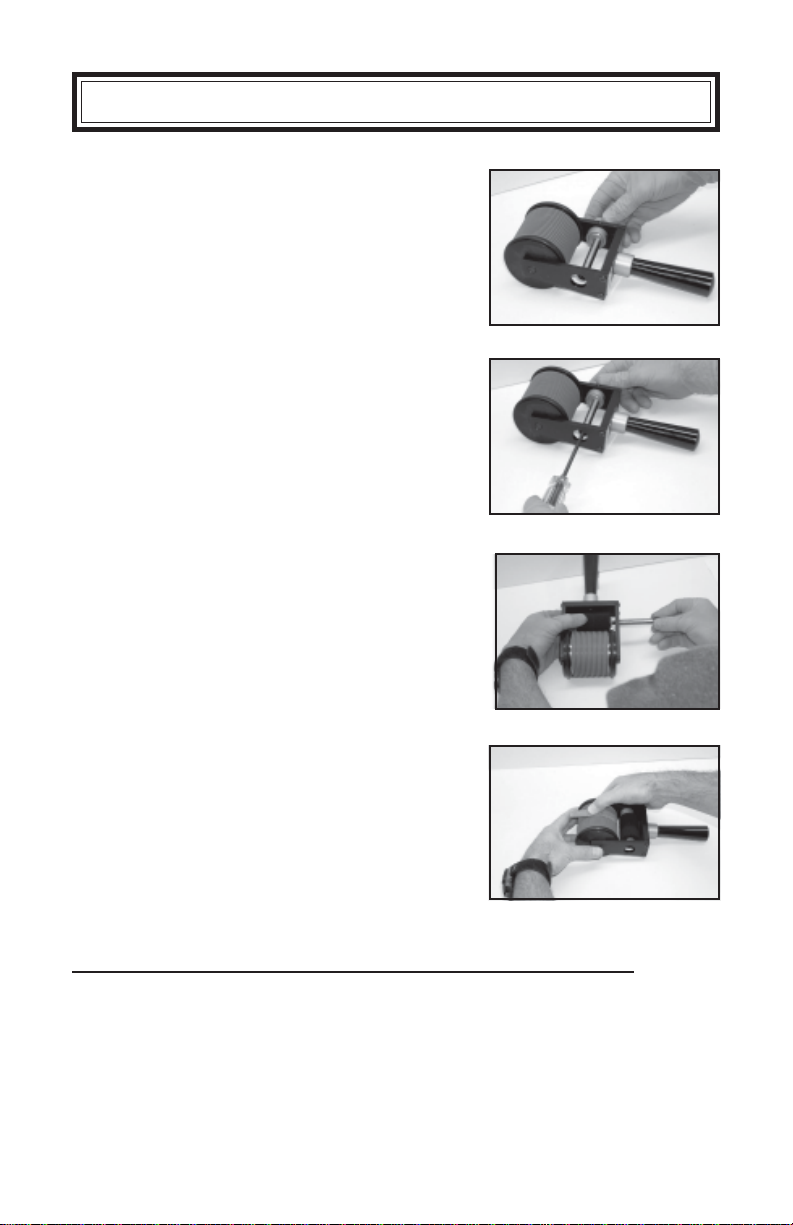

OPTIONAL TYPE BLOCKING KITS

When using small individual characters with

onlya twoor threerib backing,anoptionalType

BlockingKit (stock no.UR-BK) should beused

to support the leading and trailing ends of the

type as shown.

Characters which have only a 2 or 3 rib back-

ing do not have the stability of the larger char-

acter sizes when snapped into the drum cover.

Addingthe ribbacked typeblocks onboth ends

ofthe code willprovide addedstability andpre-

vent the characters from shifting during print-

ing. The Type Blocks are not as thick as the

Type and will not pick up ink from the Ink Roll. FIGURE 2