2

PREFACE

SPECIFICATIONS

WPNP-400NI-12-PIDS& WPNP-400NI-12T-PIDS

WPNP-400NI-12-PIDS-D & WPNP-400NI-12T-PIDS-D

Printing Dies

XFNeoprene Ink Rolls

QUICK START

Installingthe Printer

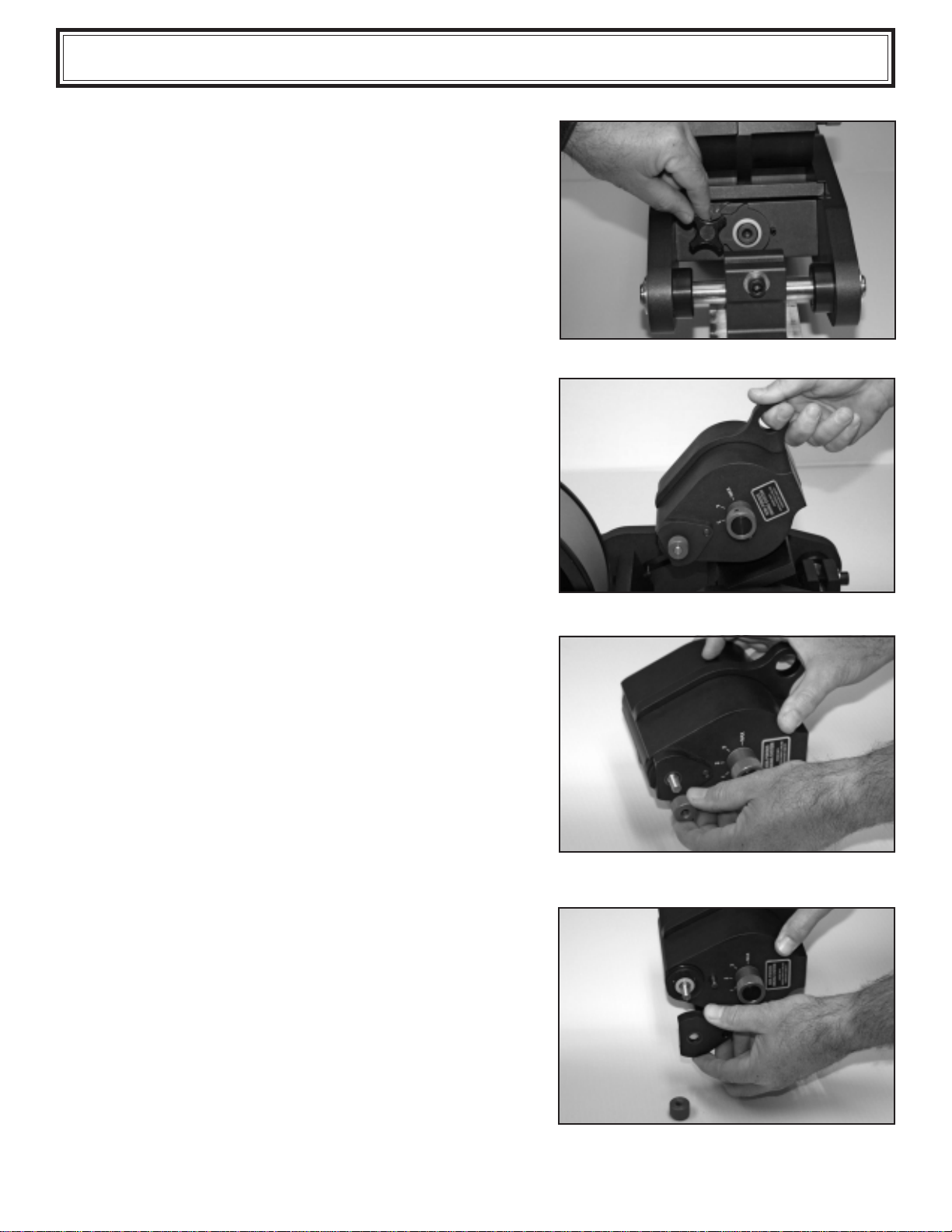

Preparing the Printer for installation of the Ink Roll

Preparing the Ink Roll for installation

InstallingtheInk Roll

Reinstalling the Inking System on the Printer

Installing the Printing Dies

Inking System PositionAdjusting Knobs

Pre-Inkingthe XF NeopreneInkRoll

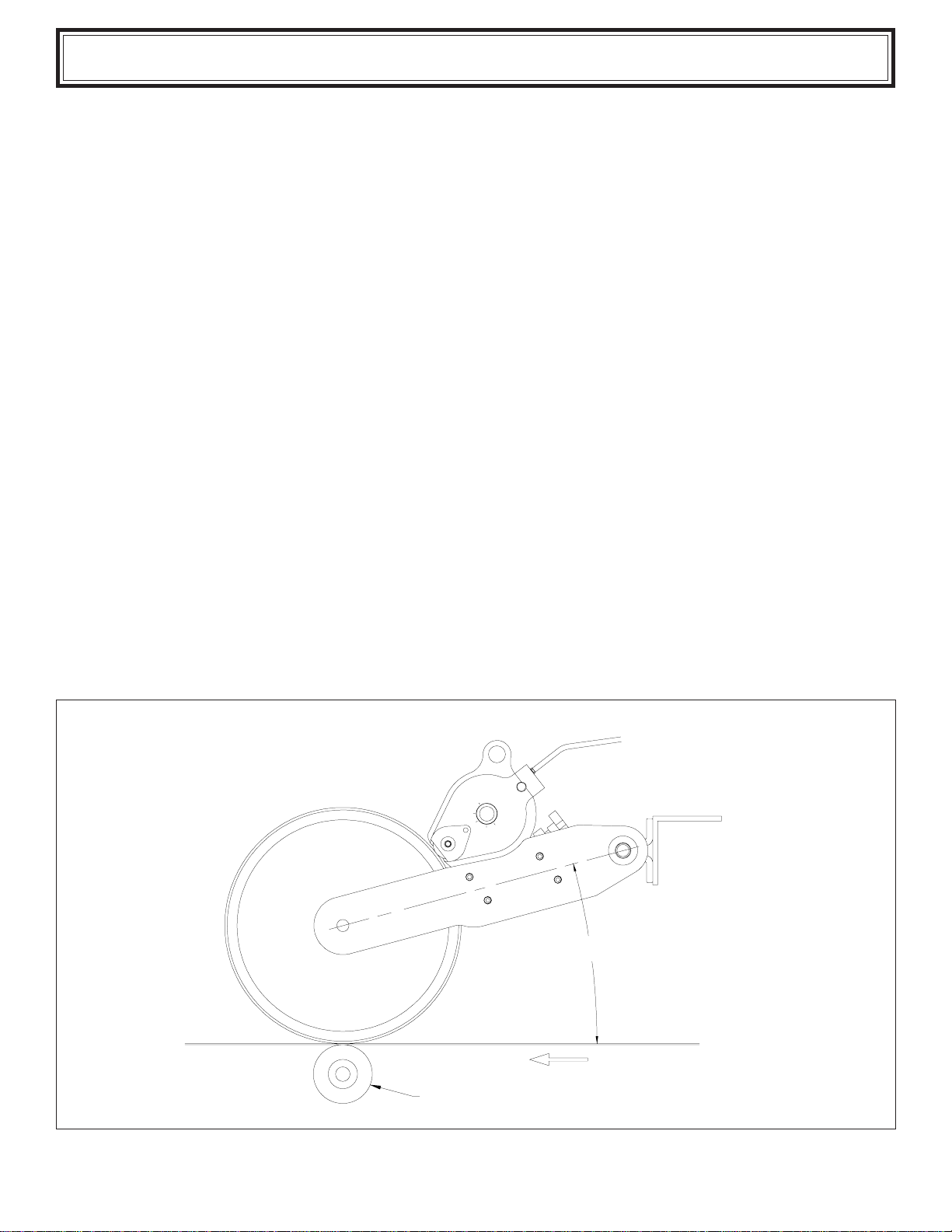

BASIC PRINCIPLES OF OPERATION

The PIDS System

HighSpeed PrintingApplications

PIDS-DIGITAL-CE Programmable Ink Delivery Systems

Encoder Sensor for Digital Models

MAINTENANCE

Adjustment of the Inductive Proximity Sensor

Cleaning the Printer

Cleaning the Transfer Roll

Cleaning the Printing Dies

PARTS DIAGRAMS & PARTS LISTS

UNIVERSALproducts are manufacturedto exacting standards and everyavailable step hasbeen taken toassure

your complete satisfaction. It is most important, however, that the instructions contained in this manual are read

and carefully followed for best results. Failure to do so may result in unsatisfactory performance, damage to the

equipment and personal injury.

IMPORTANT NOTE

- LIMITED WARRANTY -

UNIVERSALWPNP-400NI-12-PIDSWebPrintersare guaranteed tobefreefrom defects inmaterialsandworkmanship for

a period of 90 days from the date of purchase. Components found to be defective during this time will be repaired free of

charge if returned to the factory. Damage resulting from use of improper inks, improper installation, or operation is not

coveredunder thescope ofthis warranty. Forwarranty serviceplease contactour Customer Service Department.

3

4

4

5

5

6

7

9

10

12

13

13

14

15

15

15

16

17

18

18

19

20

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○