8

SAFETY

Safety Signs

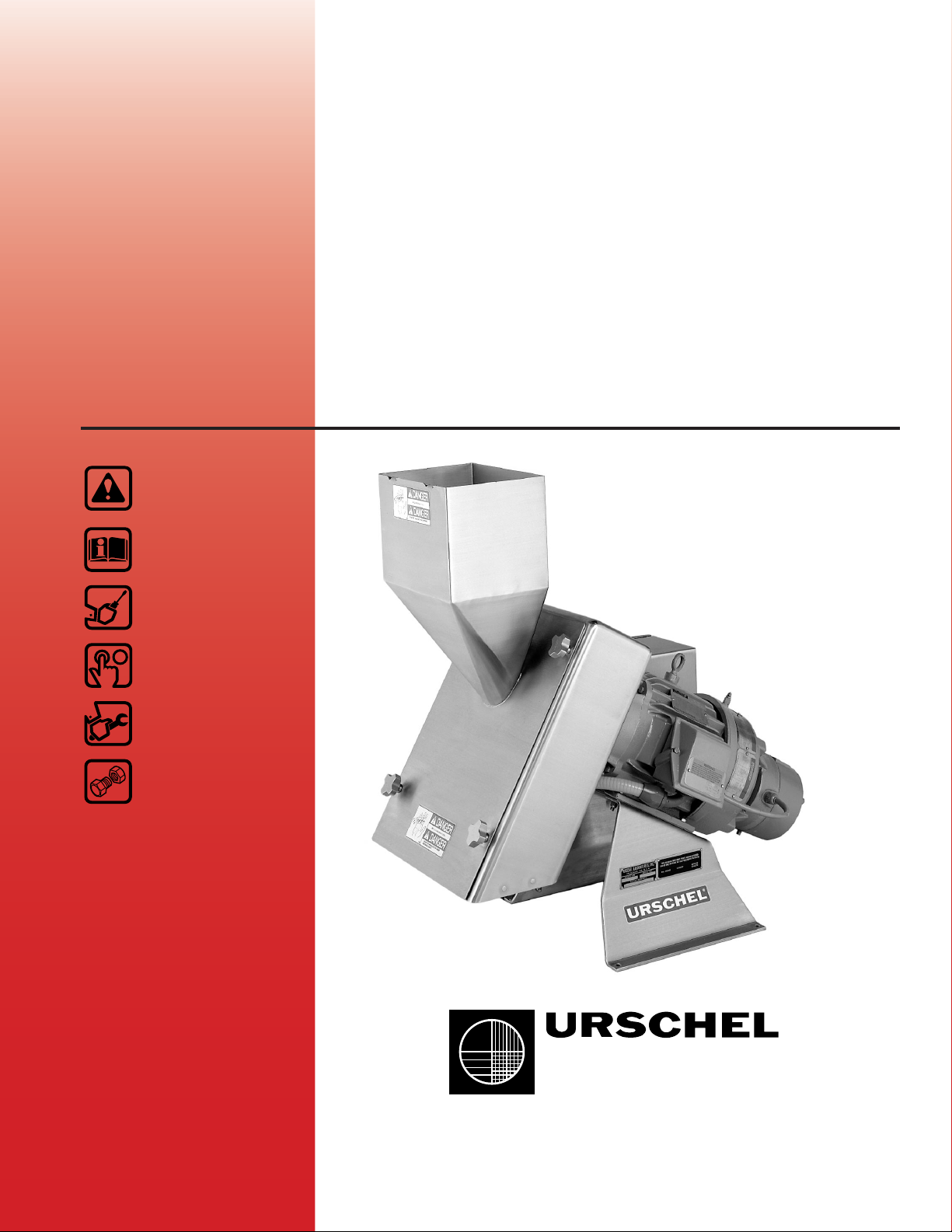

Safety signs and safety switches are placed on Urschel® machines to help you avoid

personal injury. They are there for your protection If your machine does not have

these signs or switches, you must not operate the machine. Notify your supervisor and

contact Urschel aboratories, Inc. For the part numbers, languages and locations of

safety signs, see “Safety Signs and Machine abels” in the parts section of this manual.

A caution label (Figure 1) is provided

to remind you of safety rules which

must be followed to avoid personal

injury.

Danger labels (Figure 2) are placed at

or near the feed opening to warn you

and anyone near the machine that this

opening is an access to sharp rotating

parts and pinch points which can cause

serious injury. Never insert your hand, a

tool, or any foreign object into the feed

opening.

Danger labels (Figure 3) are placed on

or near the discharge chute to warn you

and anyone near the machine that this

opening is an access to sharp rotating

parts and pinch points which can cause

serious injury. Never insert your hand, a

tool, or any foreign object into the dis-

charge chute.

11666

PRECAUCION

CAUTION

MACHINE CONTAINS ROTATING PARTS SUCH AS SHARP KNIVES, PULLEYS, BELTS OR GEARS.

NEVER RUN MACHINE WITH ANY GUARD OR COVER REMOVED, EVEN FOR CLEANING.

TURN THE MACHINE OFF, DISCONNECT AND LOCK OUT POWER SOURCE BEFORE

ATTEMPTING TO SERVICE OR REMOVE OBSTRUCTION.

RUNNING MACHINE WITH ANY GUARD OR COVER REMOVED MAY RESULT IN SERIOUS INJURY

OR AMPUTATION.

READ AND UNDERSTAND INSTRUCTION MANUAL.

LA MAQUINA CONTIENE PIEZAS GIRATORIAS TALES COMO CUCHILLAS AFILADAS, POLEAS,

CORREAS O ENGRANAJES.

NUNCA HACER FUNCIONAR LA MAQUINA CON CUALQUIERA DE LOS PROTECTORES O

CUBIERTAS RETIRADOS, INCLUSO PARA LIMPIARLA.

APAGAR LA MAQUINA, DESCONECTAR Y BLOQUEAR EL SUMINISTRO ELECTRICO ANTES DE

INTENTAR HACER UNA REPARACION O QUITAR UNA OBSTRUCCION.

SE CORRE EL RIESGO DE SUFRIR GRAVES LESIONES O AMPUTACION SI SE HACE FUNCIONAR

LA MAQUINA CON CUALQUIERA DE LOS PROTECTORES O CUBIERTAS FUERA DE SU LUGAR.

LEER Y ENTENDER EL MANUAL DE INSTRUCCIONES.

Figure 1 — Caution abel

Figure 2 — Danger abel, Feed Opening

Figure 3 — Danger abel, Discharge Chute

11662

DO NOT PUT HANDS INTO FEED OPENING.

NO PONER LA MANO DENTRO DE LA

ABERTURA DE ALIMENTACION.

DANGER

PELIGRO

11663

DANGER

PELIGRO

DO NOT PUT HANDS INTO OR UNDER

DISCHARGE CHUTE.

NO PONER LA MANO DENTRO O BAJO

EL CONDUCTO DE DESCARGA.