Safety

• Dress for the job. Choose close-fitting clothes and long pants, hearing pro-

tecttion, eye protection, work boots with traction and heavy gloves (when han-

dling blades). Do not wear loose-fitting clothes or jewelry, which can get

caught or hung up on a machine and cause injury.

• Know your machine. Read the operators manual to familiarize yourself with

your machines unique features. For example deflector shields, adjustments,

skid shoes, retention systems and maintenance.

• Read warning labels and check safety features. Never operate your mower if

your safety guards and devices are not in place. Replace safety guards and de-

vices if damaged or not operating properly.

• stop mowing if passersby are within 50 yeard radius from mower head.

• never allow children to operate, ride on, or come close to mower or equipment.

Never lift a person or allow anyone to stand on a mower head. keep bystanders

and pets clear and off of equipment.

• Extreme care should be taken when operating near loose objects such as grav-

el, rocks or general debris. These objects should be removed or avoided to

prevent injury from thrown objects. Where grass and weeds are high enough

to hide debris that could be struck by the blades, the area should be inspected

and large debris removed. Mow cleared area at an intermediate height, inspect

closely for remaining debris and remove. Mow again at desired final height.

• Keep the mower head at least 10 feet from electric lines and pipe lines to pre-

vent accidental contact and possible serious injury or even death.

• Pressurized hydraulic fluid can penetrate the skin causing serious injury. Do

not use your hand to check for leaks on a pressurized system. Use a piece of

cardboard or paper to search for leaks. Stop the engine and relieve pressure

before connecting or disconnecting lines. Tighten all connections before

starting the engine or pressurizing lines. If fluid is injected into the skin, ob-

tain medical attention immediately.

• Check attachment points. Check your mower’s connection to the power unit. All

pins, bushings and linkage should be checked to insure they are free to travel

the full distance without interference. Repair if necessary.

• Conduct daily inspections. Verify that all shields and guards are in proper

working order. Check blade attachment bolts to insure all blades are present

and in good condition. Check blades for cracks around bolt hole. Check that

hydraulic hose connections are completely engaged.

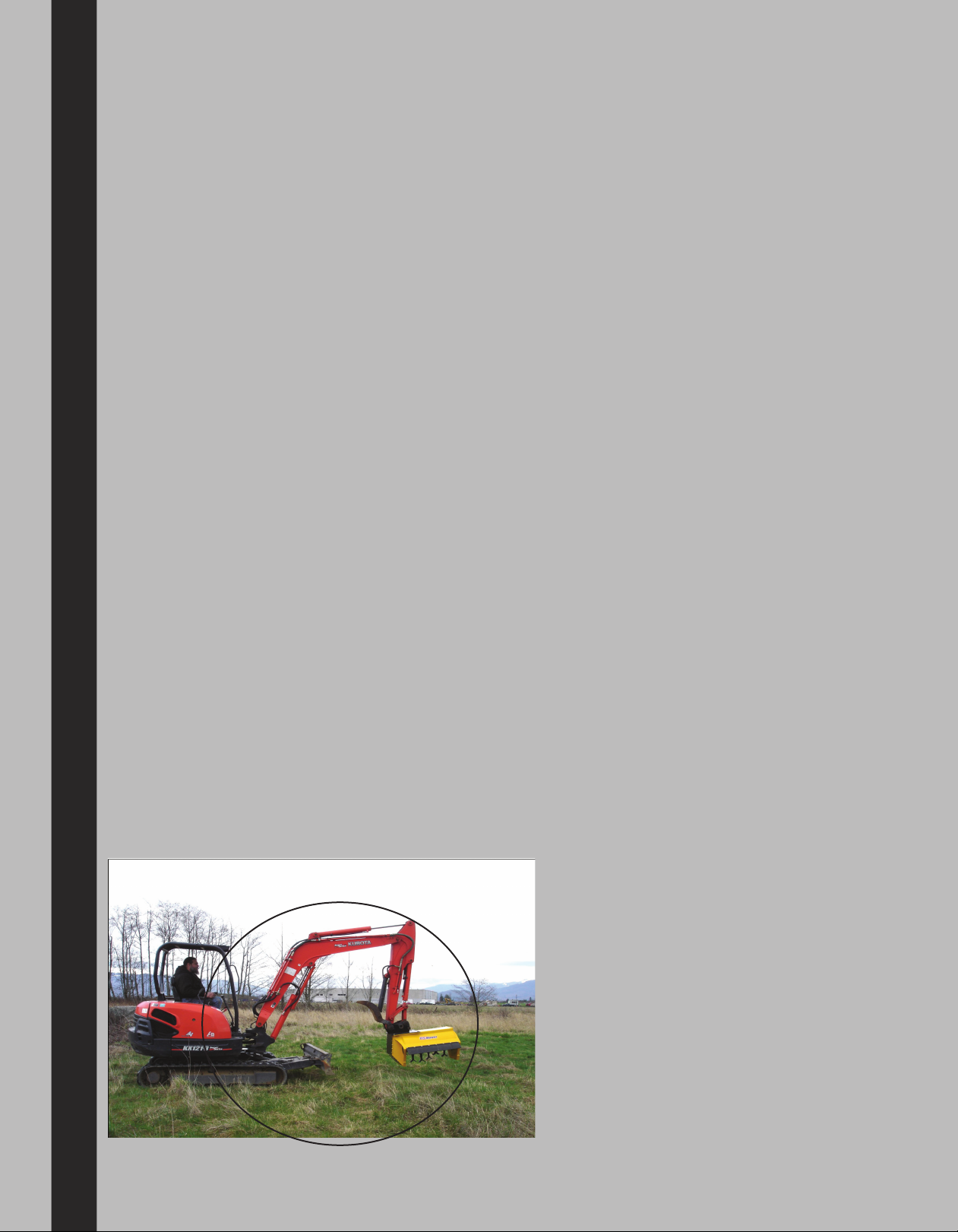

Operating Safety Zone---50 Yard Radius

from Mower Head

Stop! And allow all vehicles to

pass through operating “Safety

Zone” before continuing cutting.

Operator awareness is key to safe

operation. Never operate or con-

tinue to operate this machine when

there is a person or vehicle with-

in a 50 yard radius of the cutting

operation. If a person comes in-

side your operating “Safety Zone”

(50 yard radius) shut the machine

down.

KNOW YOUR OPERATING SAFETY ZONE!!