USRESTAURANT® RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT NOTICE

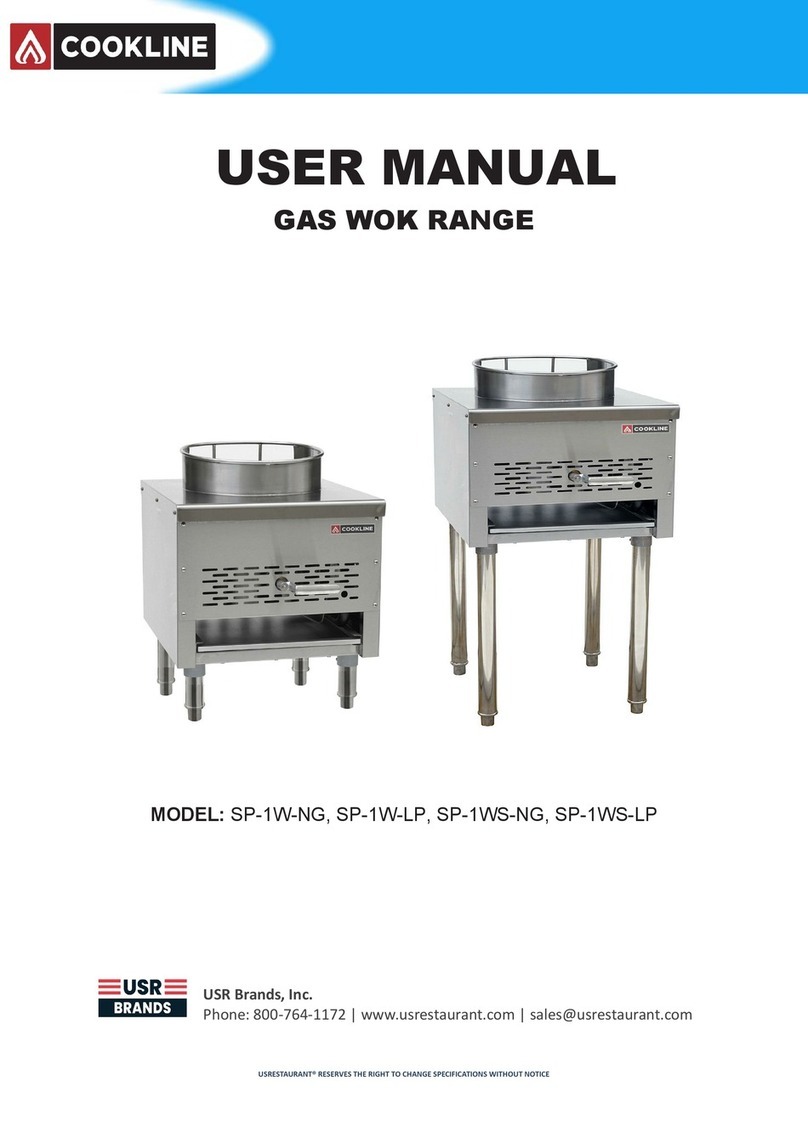

SET UP

1. Remove all packing material and tape, as well as any protective plastic from the

equipment.

2. Place the equipment in the desired position and height.

3. Install the four (4) legs onto the equipment.

4. Clean and dry the equipment thoroughly before using.

INSTALLATION:

The installation of this equipment must conform with local codes, or with the National

Gas Code, ANSIZ223.1/NFPA 54, or the

Natural Gas and Propane Installation Code, CSA B149.1, as applicable.

• The equipment and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of ½ psi

(3.5 kPa).

• The equipment must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psi (3.5 kPa).

Clearance and positioning around the equipment:

The installation location must be kept free and clear of combustibles. Do not obstruct the

flow of combustion and ventilation air. DO NOT install the stockpot adjacent to open burners

or fryers.

Sufficient air should be allowed to enter the room to compensate for the amount of air

removed by any ventilating system and for combustion of the gas burners. Do not obstruct

the air flow into and around the appliance. Do not obstruct the f low of flue gases through

and above the stockpot top grate. Position the stockpot in its final location. Check that there

are sufficient clearances to service the stockpot and to make the required gas supply

connect ion(s). Provide 24" clearance at the front for cleaning, maintenance, service and

proper operation.

Non-Combustible

Construction

Air Supply and ventilation:

• The area in front and around the equipment must be kept clear to avoid any obstruction of

the flow of combustion and ventilation air.

• Adequate clearance must be maintained at all times in front of and at the sides of the

equipment for servicing and proper ventilation.

Pressure Regulator:

• All commercial cooking equipment must have a pressure regulator on the incoming service

line for safe and efficient operation. The regulator provided for this equipment is adaptable

for both Natural gas and LP gas.

• Regulator specifications: ¾” NPT inlet and outlet, factory adjusted for 4” WC Natural Gas