INSTALLATION INSTRUCTIONS

WWW.UTOPIAGROUP.COM

page 2

Contents

Base Units

Fitting Base Units 3

Base Units and Drawer Packs 3

Fitting Wall Hung Base and Wall Units 4

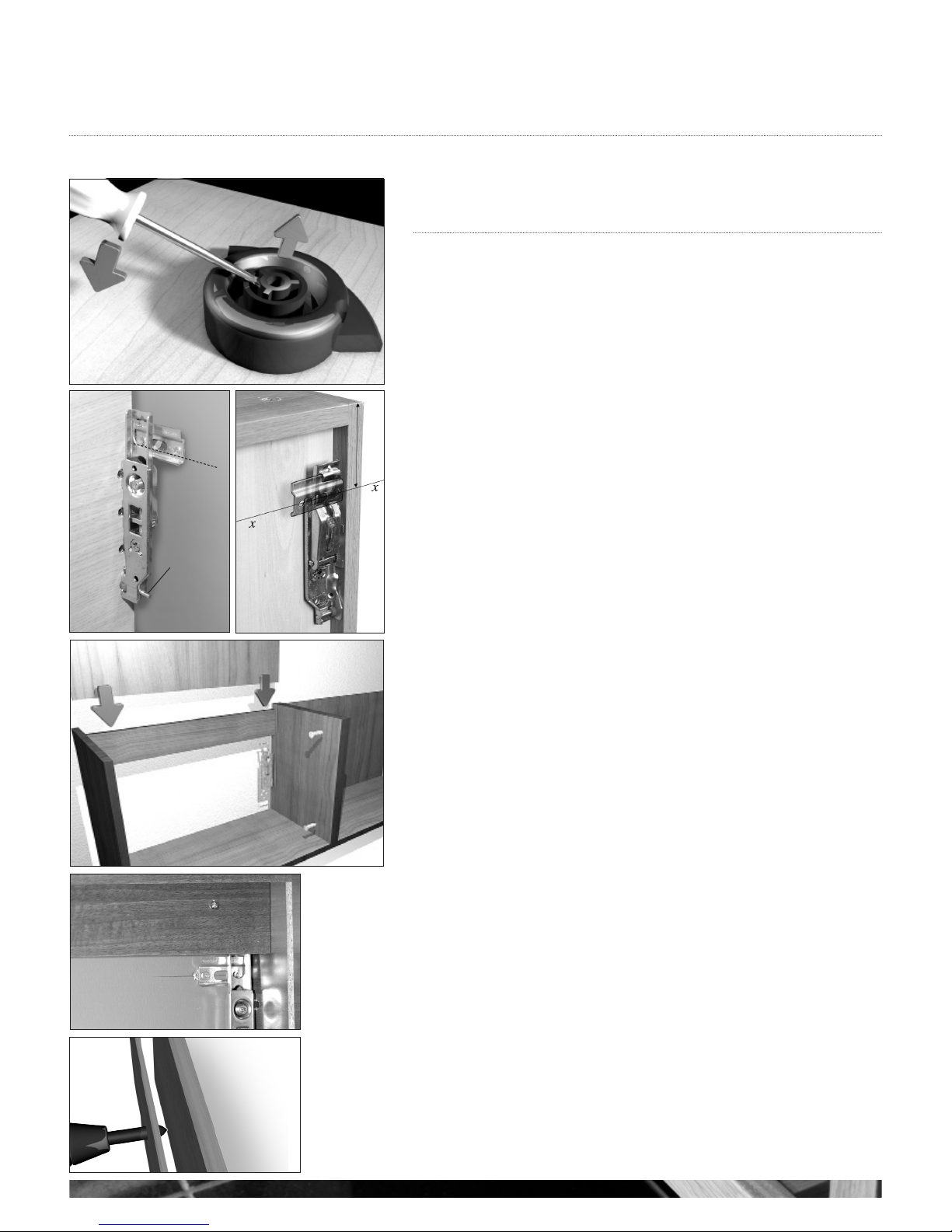

Adjusting a Soft Close Drawer Box 5

Fitting a Plinth 5

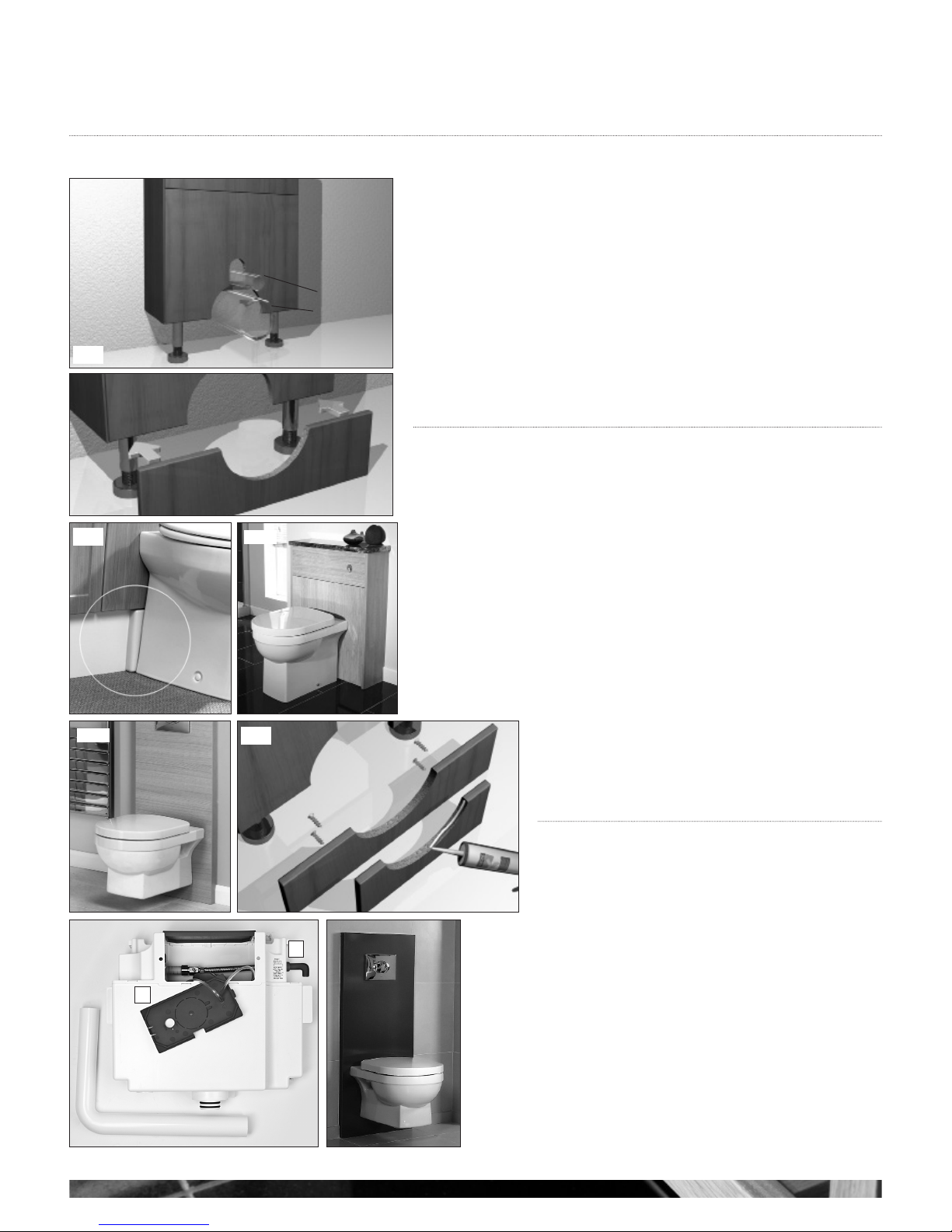

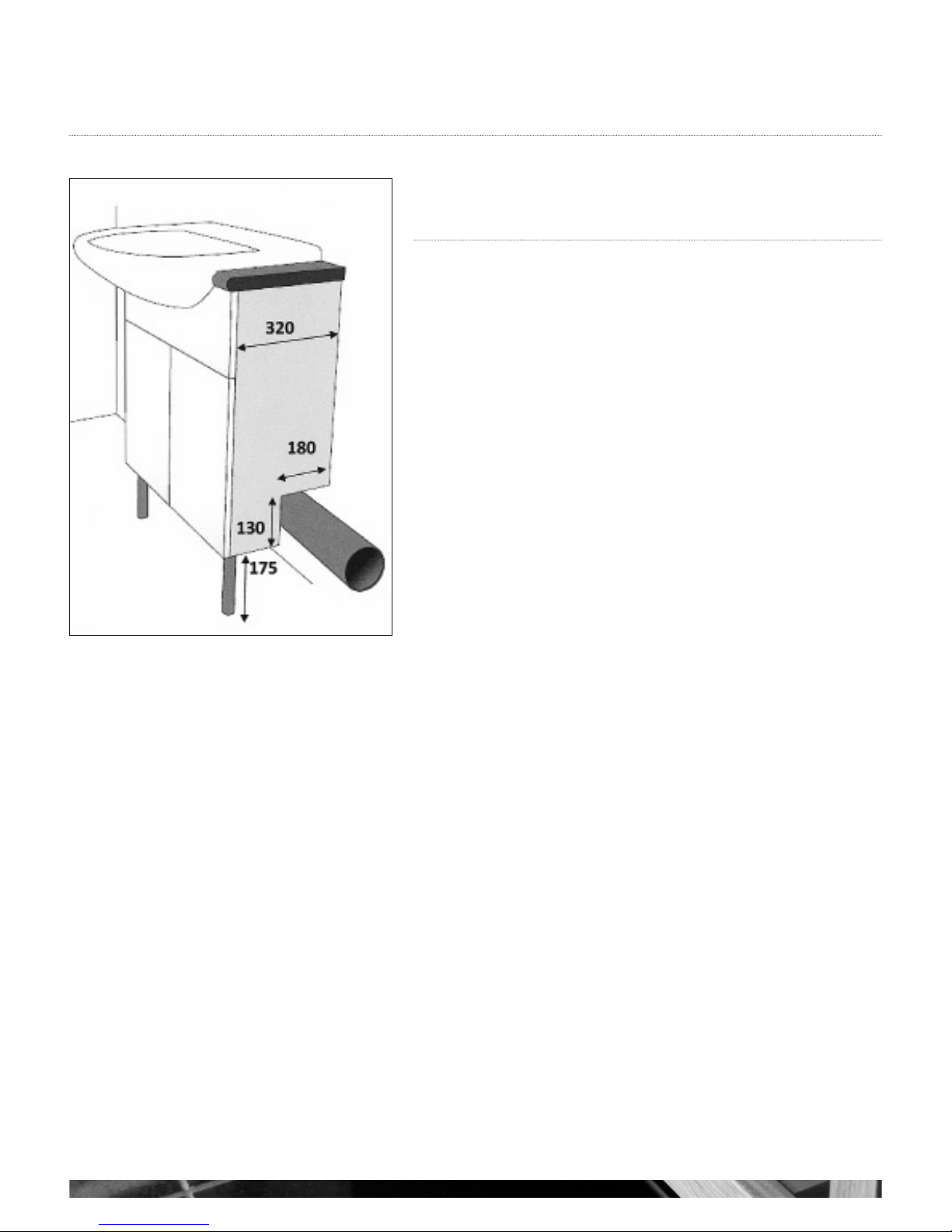

WC Fascia Cut Outs 6

Utopia Push Button Concealed Cisterns 6

Dual Flush Push Button Cistern Features 6

WC Panels 6

Cut-Out Semi Recessed Washbasin Units 7

Wall Units

Fitting Wall Cabinets 8

Fitting the Lighting Unit 8

Access and Removal of Transformers and Front Fascia 8

Mirror Cabinet Handle Fitting 9

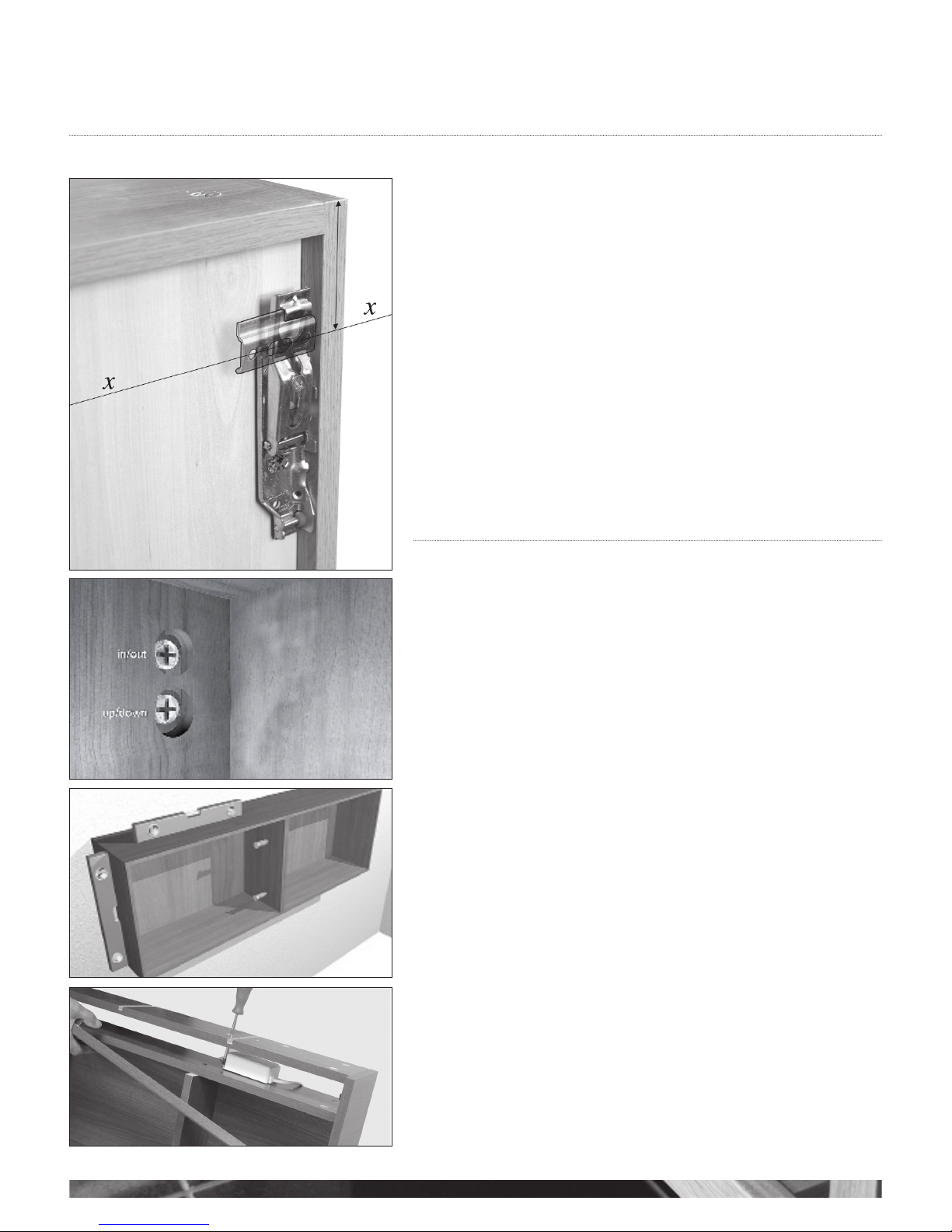

Door Adjustment 9

Fitting a Mirror Door onto a Unit 9

Soft Close Hinge Mechanism, Removal and Re-Fitting 9

Mirrors

Fitting a Mirror 10

Fitting Designer Illuminated, Curved and Modular Offset Mirrors 11

Lighting, Flyover Shelves and Cornice

Fitting Flyover Shelves 12

Fitting LED Downlighters 12

Fitting Chrome Bow Lights 12

Fitting Wall Mounted Mirror Lights 12

Tall Units

Fitting a Tall Glass Shelf Display Unit and

All Other Tall Units 13

Modular Units

Fitting Wall Hung Base and Wall Units 14

Modular Mirror Fitting 15

Modular Sliding Mirror 15

Mirror Cabinet Handle Fitting 16

Door Adjustment 16

Fitting a Mirror Door on to a Unit 16

Soft Close Hinge Mechanism, Removal and Re-fitting 16

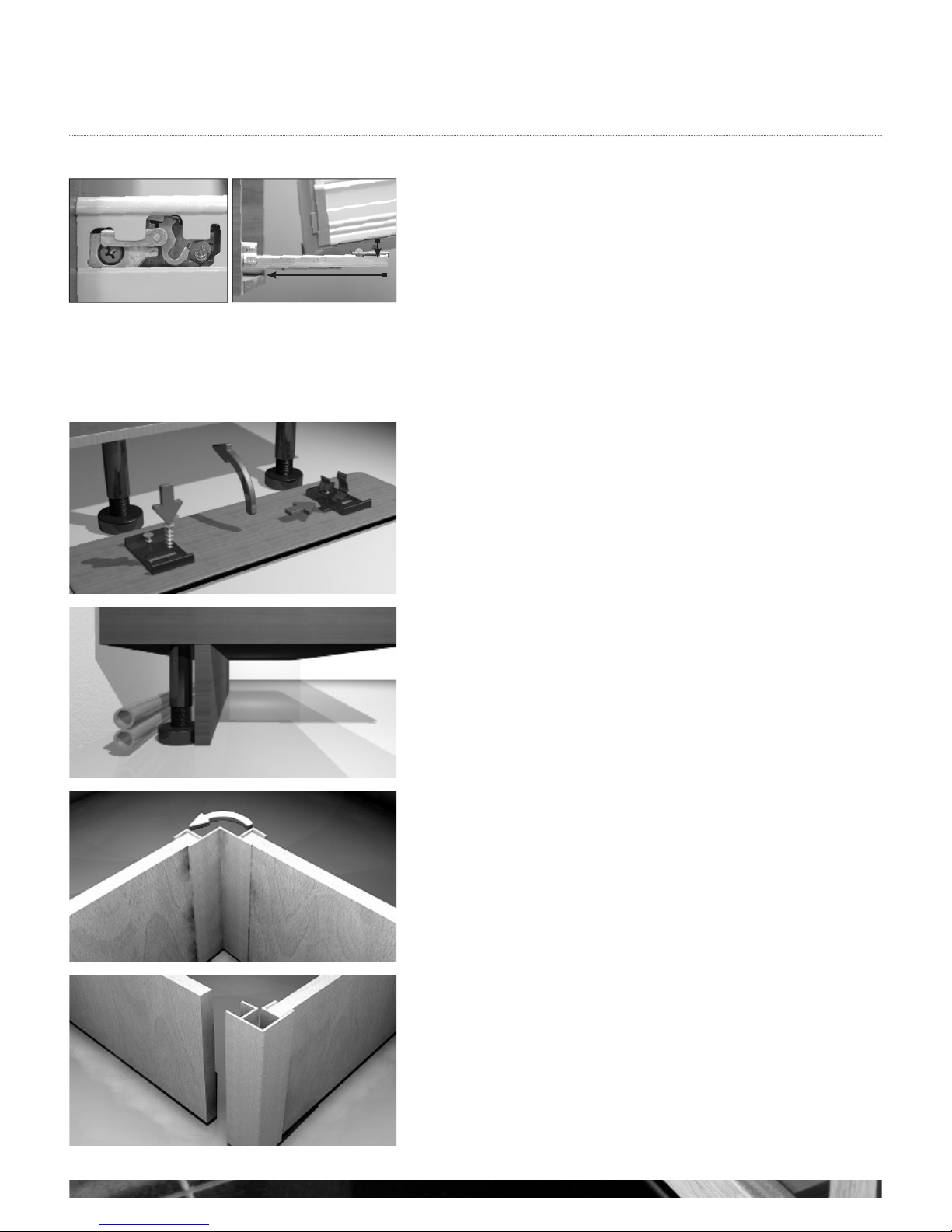

Fitting a Square Profile Laminate Worktop 17

Basin Waste Recommendation 17

Adjusting a Soft Close Drawer Box 17

Halo and Qube Furniture

Fitting Hinged Door Mirror Unit 18

Fitting Mirror Drawer Unit 18

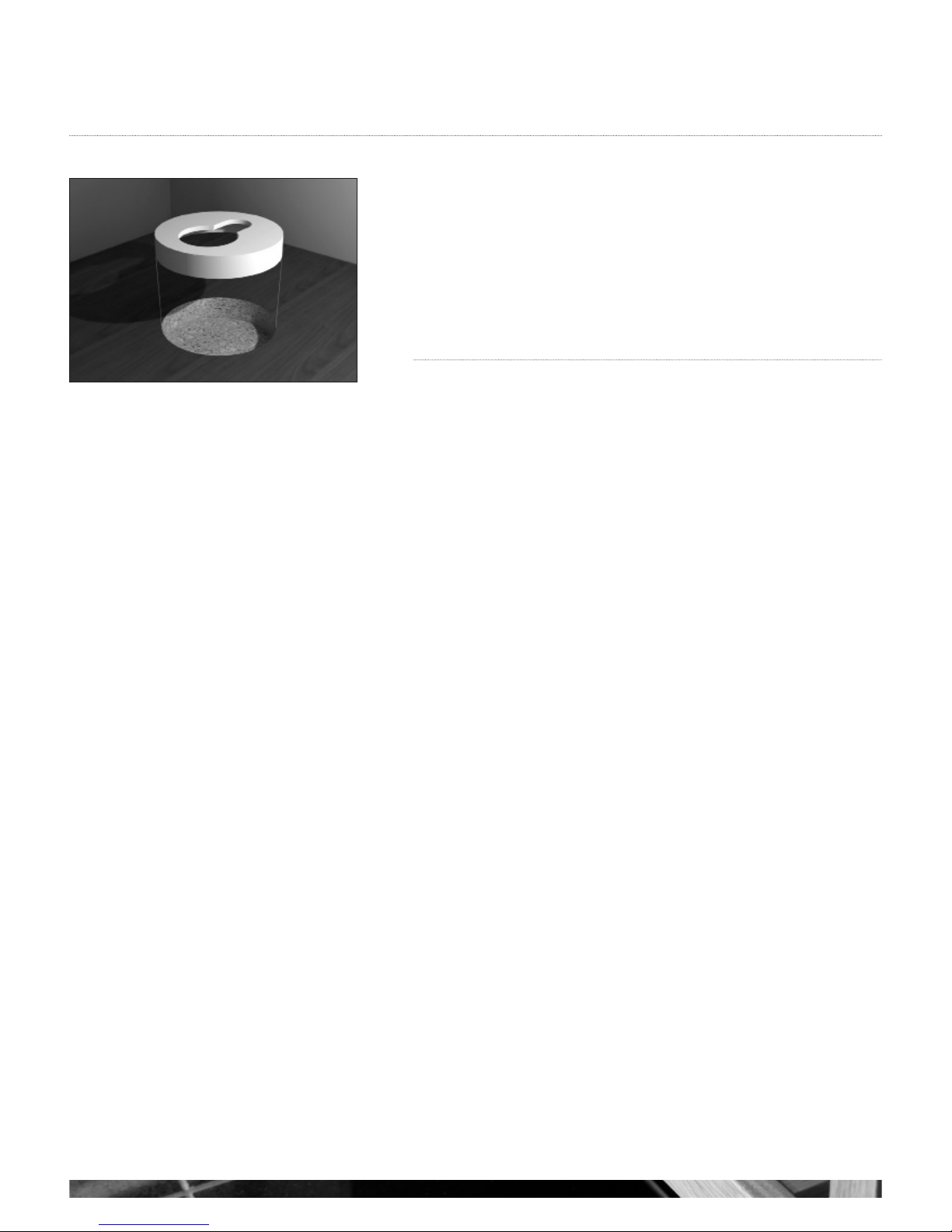

Fitting Qube Unit 19

Fitting Halo Twin Base Unit 19

Fitting Side Cabinet 20

Fitting Cloakroom Cabinet 20

i-Line Furniture

Fitting i-Line 50mm Side Panels 21

Fitting i-Line Wall and Mirror Units 22

Symmetry Furniture

Fitting Symmetry Modular Fitted/Freestanding Base Units 23

Fitting Symmetry Worktops / Solid Surface 23

Decorative End Panels 24

Fitting Side Panels with an External Filler Panel 24

Fitting Symmetry Plinths 24

Plinth Lighting 24

Downton

Fitting Traditional Base Unit 25

Downton 26

Bath Panels

Bath Panel Component Identification 27

Bath Panel Installation 27

Definity Fitted Bath 28

Free-standing Bath 29

Fitting Symmetry Baths 30

Fitting Symmetry Bath Side Panels 30

Fitting Symmetry panels with end storage unit 30-32

Geo

Geo Drawer Unit 35

Geo Integra Solid Surface and Freeflow Basin 35

Tap Holes

Drilling For Taps in the Worktop 36

Drilling a Tap Hole In a Gelcast Cloakroom Washbasin 36

50mm Laminate Worktops 36

Solid Surface and Laminate Worktops

Installation of Laminate and Solid Surface Worktops 37

Fitting a Worktop 38

Installing a Washbasin into a Worktop 39

Washbasin Fascia and Worktop Cut Outs 39

Washbasin Waste Recommendation 39

Fitting a Solid Surface Apron Standard

and Short Projection 40

Solid Surface Shelves and Shelf Supports 40

50mm Decorative Floating Shelves

Fitting a 50mm Shelf with an Adjustable Support 41

Roseberry Painted Products

Fitting Instructions 42

Modular 2017 ( Star, Lustre, Opula )

Fitting Instructions 53

Care and Maintenace

Important Note

These fitting instructions refer to fitting Utopia

Furniture to a solid wall. If your bathroom has

studded walls, please use appropriate plasterboard

fixings such as the ones illustrated here, available

from DIY stores throughout the UK.

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE COMMENCING WORK

All units are packed together with a relevant fitting pack and are identified by a label which appears on the front of the box and the rear of the unit.

It is advised that fitting commences from a corner wherever possible, ensuring correct spacing should a corner filler be used.

It is also advised that all doors and fascias are removed prior to fitting to avoid unnecessary damage occurring.

Please note that some of Utopia’s units, sanitaryware and worktops are heavy. Always take care when lifting, and follow health and safety guidelines.