Проверил: Р.Ч./08.2017г.

h. When practical, remove gas-powered equipment from the truck or trailer and refuel it on

the ground. If this is not possible, then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser nozzle.

i. Keep the nozzle in contact with the rim of the fuel tank or container opening at all times,

until refueling is complete. Do not use a nozzle lock-open device.

j. Replace gasoline cap and tighten securely.

k. If gasoline is spilled, wipe it off the engine and equipment. Move machine to another area.

Wait 5minutes before starting the engine.

l. Never store the machine or fuel container inside where there is an open flame, spark or

pilot light(e.g. furnace, water heater, space heater, clothes dryer etc,)

m. Allow machine to cool at least 5 minutes before storing.

n. If fuel is spilled on clothing, change clothing immediately.

Operation

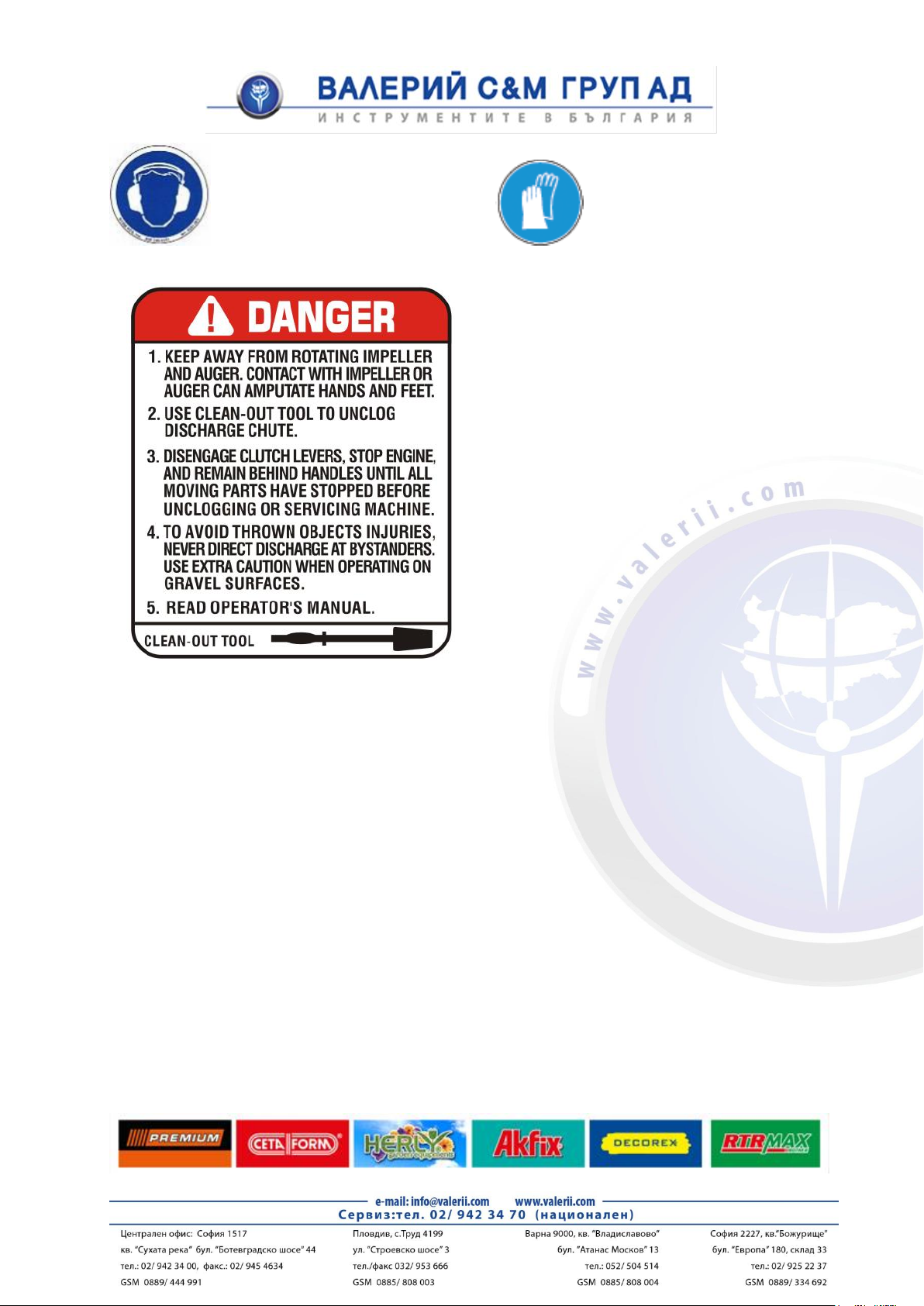

1. Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet. Keep clear of the discharge

opening at all times.

2. After striking a foreign object, stop the engine (motor), remove the wire from the spark plug,

disconnect the cord on electric motors, thoroughly inspect the snow thrower for any damage,

and repair the damage before restarting and operating the snow thrower.

3. Stop the engine (motor) whenever you leave the operating position, before unclogging the

collector/impeller housing or discharge chute, and when making any repairs, adjustments or

inspections.

4. When cleaning, repairing or inspecting the snow thrower, stop the engine and make certain

the collector/impeller and all moving parts have stopped. Disconnect the spark plug wire and

keep the wire away from the plug to prevent someone from accidentally starting the engine

5. The auger/impeller control lever is a safety device. Never bypass its operation. Doing so

makes the machine unsafe and may cause personal injury.

6. The control levers must operate easily in both directions and automatically return to the

disengaged position when released.

7. Never operate the snow thrower without proper guards, and other safety protective devices in

place and working.

8. Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

9. Do not operate machine while under the influence of alcohol or drugs.