Van der Ende Groep · Aartsdijkweg 23, 2676 LE, Maasdijk · Tel: 0174 515050

IBAN

NL71

RABO

0340341610

· CC The Hague 27230471 · VAT-number NL8000.78.378.B01 · [email protected] · www.vanderendegroep.nl

Contents

Foreword ...................................................................................................................................... 2

Contents ....................................................................................................................................... 3

1. Identification ............................................................................................................................. 4

1.1 General................................................................................................................................ 4

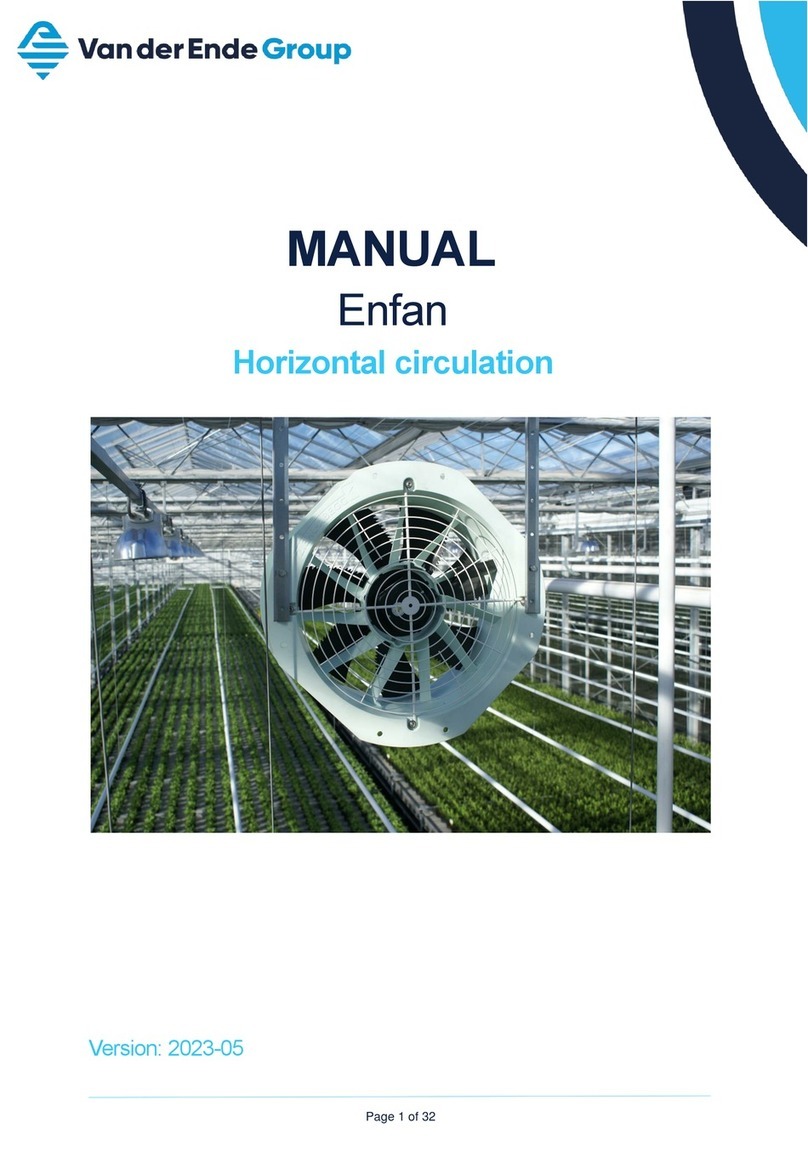

1.1.1 Description of the device ................................................................................................ 4

1.1.2 Specifications................................................................................................................. 4

1.1.3 Diagram of the system ................................................................................................... 5

1.2 Users................................................................................................................................... 6

1.3 Use ..................................................................................................................................... 6

1.4 Authorised servicers ............................................................................................................. 6

1.5 Operating environment ......................................................................................................... 6

1.6 Guarantee conditions............................................................................................................ 6

1.7 Relevant directives ............................................................................................................... 6

2. Description................................................................................................................................ 7

2.1 General................................................................................................................................ 7

2.2 Transportation and Storage .................................................................................................. 7

3. Safety instructions ..................................................................................................................... 7

4. Installation................................................................................................................................ 8

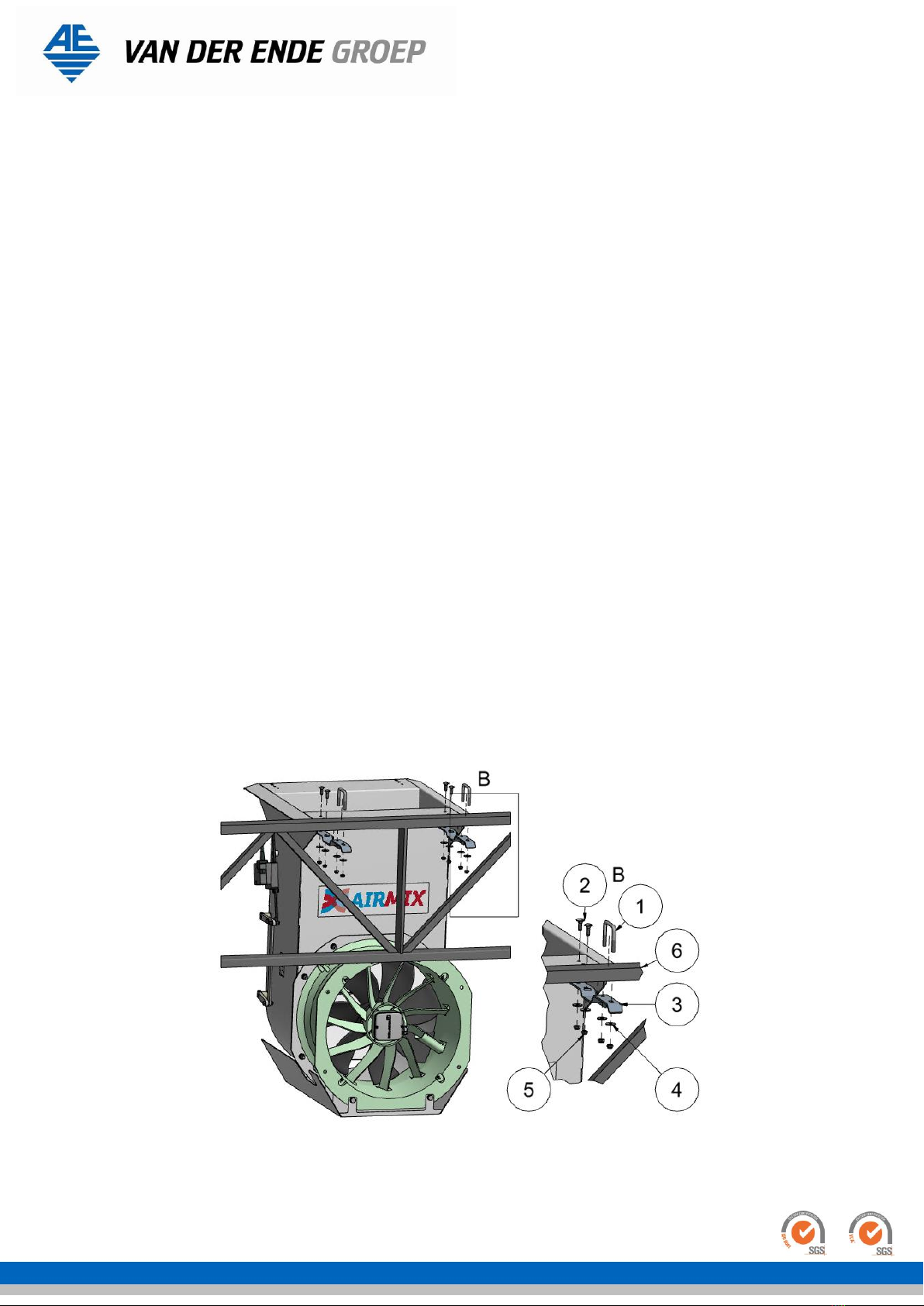

4.1 Contents of the installation kit............................................................................................... 8

4.2 Suspending the Airmix™ ....................................................................................................... 9

4.2.1 Mounting directly under the truss lattice .......................................................................... 9

4.2.1 Mounting with suspension brackets ................................................................................10

4.3 Attaching the fan.................................................................................................................11

4.4 Installing the extension........................................................................................................13

4.5 Installing the spacer ............................................................................................................14

4.6 Installing the valve position sensor .......................................................................................15

4.7 Modifying the screen cloth ...................................................................................................16

5. Connecting the thermostatic switch ...........................................................................................16

6. Operation/using for the first time...............................................................................................18

6.1 Gear-rack drive ...................................................................................................................18

7. Maintenance ............................................................................................................................19

8. Failures and repairs ..................................................................................................................19

9. Disassembly .............................................................................................................................19

10. Declaration of Conformity........................................................................................................20

Attachments ................................................................................................................................21

CE declaration concerning fan....................................................................................................22

CE declaration concerning linear drive ........................................................................................23

Note ............................................................................................................................................24