8 VANAIR.COM • 800-526-8817 START•ALL®HYDRAULIC SERIES TROUBLESHOOTING GUIDE

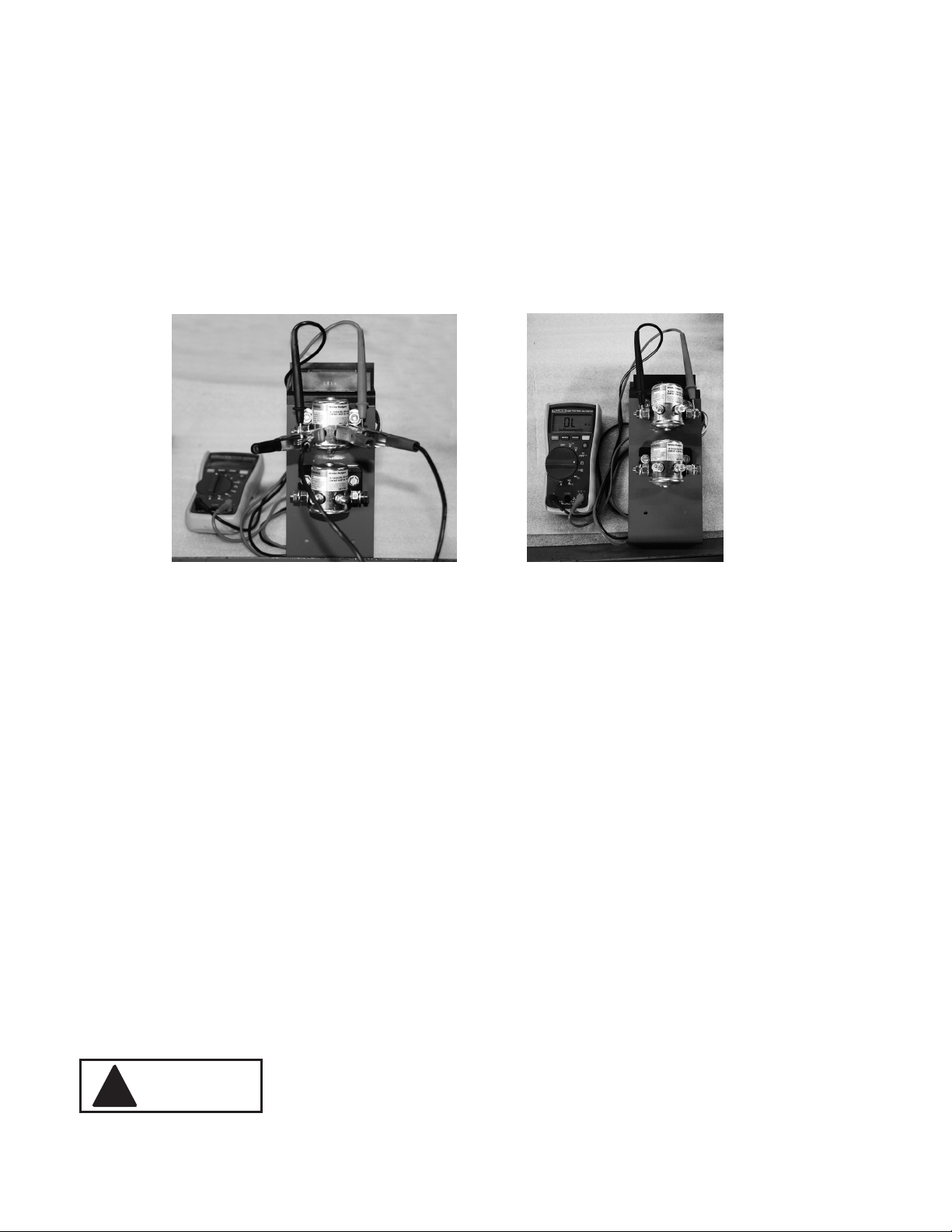

12/24 VOLT RED LABEL VOLTAGE CONTROL SWITCH TESTS

In the “ON” position, the switch connects the Armature output to the orange wire on the regulator and the

appropriate solenoids for the selected voltage. This test is performed with an ohmmeter or continuity tester.

CHECK THE “OFF” POSITION

1. With the switch in the “OFF” position, check for continuity between any combination of the red, orange,

black and purple wires.

2. Is there continuity present?

a. If YES - The switch has an internal short. Replace switch assembly.

b. If NO - This portion of the switch is working correctly. Proceed to ‘Check the “ON” Position for 12V Side’

section.

CHECK THE “ON” POSITION FOR 12V SIDE

1. Move the switch to the “12V” position.

2. Measure for continuity between the red and black wires coming from the switch.

3. Is there continuity between the red and black wires?

a. If YES - This portion of the switch is working correctly. Proceed to the ‘Check Continuity on Orange/Black

Wires (1)’ section.

b. If NO - This portion of the switch is not working correctly. Replace switch assembly.

CHECK CONTINUITY ON ORANGE/BLACK WIRES (1)

1. Measure for continuity between the orange and black wires coming from the switch.

2. Is there continuity between orange and black wires?

a. If YES - This portion of the switch is working correctly. Proceed to ‘Check the “ON” Position for 24V Side’

section.

b. If NO - This portion of the switch is not working correctly. Replace switch assembly.

CHECK THE “ON” POSITION FOR 24V SIDE

1. Move the switch to the “24V” side.

2. Measure for continuity between the purple and black wires coming from the switch.

3. Is there continuity between the purple and black wires?

a. If YES - This portion of the switch is working correctly. Proceed to ‘Check Continuity on Orange/Black

Wires (2) section.

b. If NO - This portion of the switch is not working correctly. Replace switch assembly.

CHECK CONTINUITY ON ORANGE/BLACK WIRES (2)

1. Measure for continuity between the orange and black wires coming from the switch.

2. Is there continuity between orange and black wires?

a. If YES - This portion of the switch is working correctly. Proceed to Energize Button Test.

b. If NO - This portion of the switch is not working correctly. Replace switch assembly.

ENERGIZE BUTTON TEST

CHECK THE ENERGIZE BUTTON

1. With the engine key in the “ON” position, use the voltmeter to check the voltage between the wire coming

from the engine battery and the frame ground.

2. Does the voltage measure at least 12V?

a. If YES - Voltage coming from the engine battery is good.

b. If NO - Ensure that engine starting battery is good and fully charged. Repair/replace wire from battery if

necessary.

On 12/24V Start•All®units, there is a red momentary-contact push button switch labeled “ENERGIZE”.

Pressing the energize button connects the engine-starting battery through a resistor and diode to the eld

terminal of each generator. The purpose of this circuit is to feed a small amount of current to the generator

eld coil if the switch is set to either “12V” or “24V” so that the generator output will build up to the point that

the regulator takes over control of the generator eld current.