Typical applications crane industry

■ Port tire cranes, portal cranes

◆ Reliable brake control time sequence to ensure safe and reliable;

◆ Unique torque verification feature ensures the heavy will not have slip phenomenon

when the brake release;

◆ Innovative power optimization and optimization functions ensure that the motor can up to

operation efficiency maximization by safety rated power;

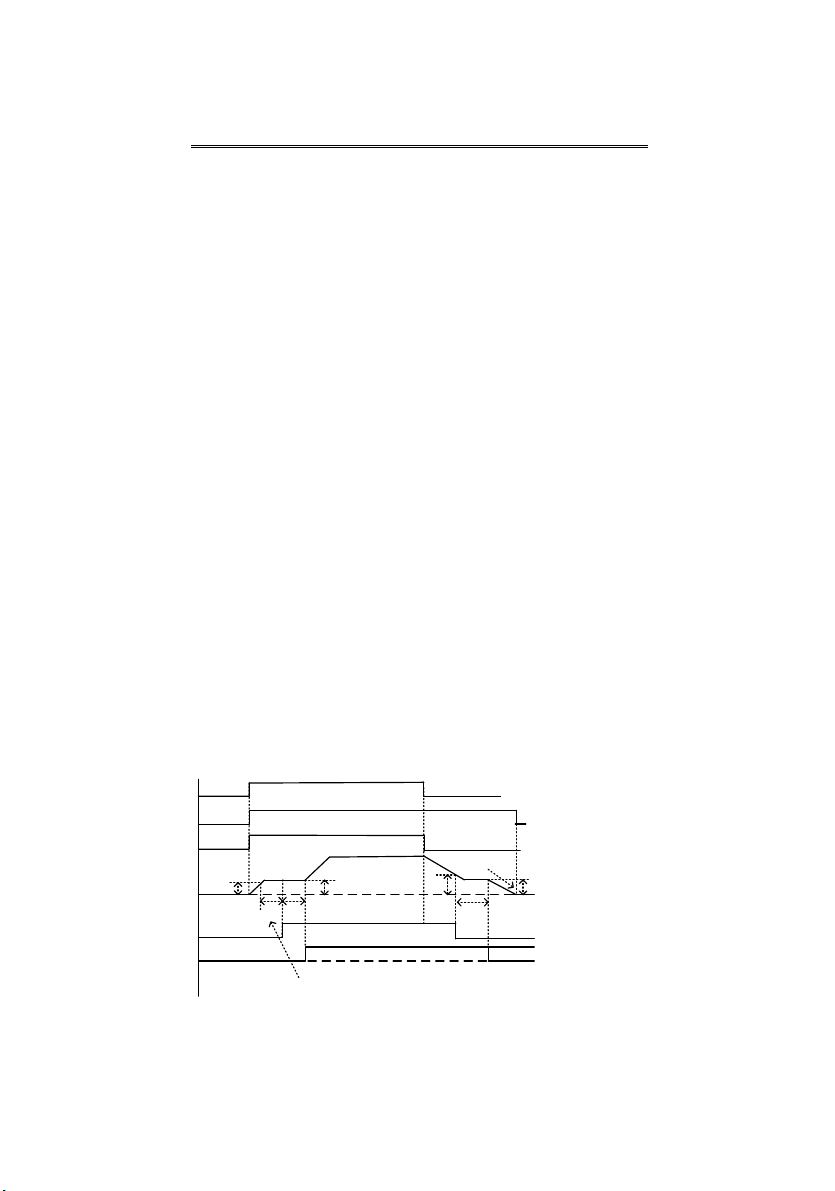

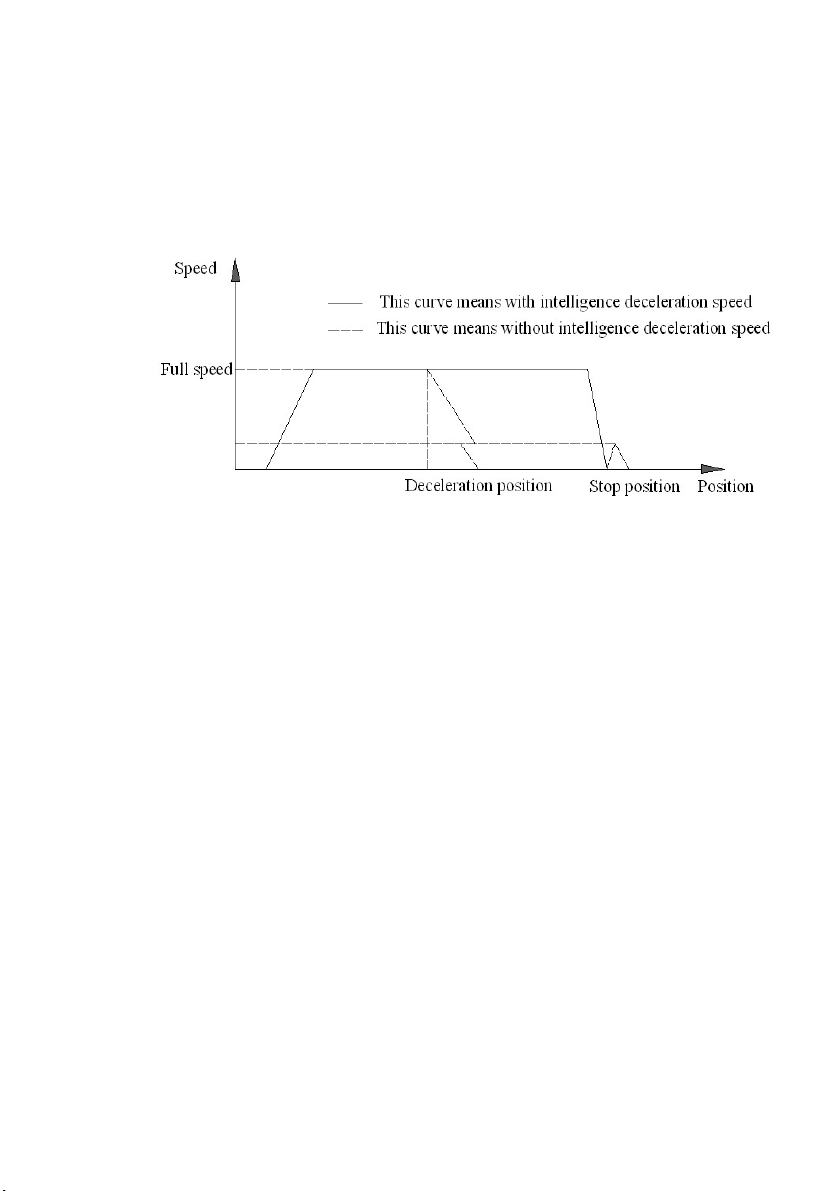

◆ Precise position control and intelligent deceleration function to ensure the system more

secure and reliable, and through intelligent deceleration to prevent upward to the top

phenomenon;

◆ fast response capability ensures easy operation, easy jog to position operation;

◆ Powerful zero speed torque to ensure safety and reliability of the whole system;

◆ Optimized communication format, greatly improving the efficiency and speed of

communication;

◆ Compatible with a variety of communication modes to meet the communication needs of

different systems.

■ Tower cranes/ lifts

◆ Arbitrary acceleration and deceleration and arbitrary impact load conditions, the inverter

runs stable without tripping on the premise of improving energy efficiency;

◆ Strong ability to adapt to the environment, to ensure that the inverter in the wind, rain,

sun, strong vibration and other harsh outdoor environment safe and reliable operation;

◆ Powerful low frequency torque to ensure that does not occur slip phenomenon when

heavy objects is upward;

◆ Excellent control performance ensure that the system is compatible with the open-loop

and closed-loop control;

◆ No need independent fault reset button, intelligent fault reset mode, making the system

easy to operate, more secure and reliable;

◆ optimized lift control logic, making the rise and fall during the startup and shutdown

smoothly without shocks.

■ Electric hoist, overhead crane

◆ Modular electric hoist special inverter, installation easier;

◆ The characteristics of the motor in the tapered, development control software for conical

motor, the inverter perfect integrated with conical motor;

◆ Accurate low speed vector running algorithm to ensure that low-speed region can

achieve sufficient startup ability to prevent slip hook phenomenon;

◆ No need auto tuning normal operation of the performance without affecting, truly

maintenance free debugging features;

◆ High reliability, low cost nature, no need PLC control circuits, simplifying the technical

program, the protection of the product quality and safety of the premise, reduce