** REMOVE THE CLEAR HEATER / SENSOR PROTECTOR SHEET BEFORE OPERATING THE DRYER **

(protector sheet is located between the heater face and the sensor bracket)

- At the end of all shifts and / or production runs, follow the Dryer Shutdown Procedure posted on the front of the

dryer and in Dryer Operation.

- Any restriction in the dryer exhaust may result in excessive heat buildup within the chamber.

More information in Dryer & Exhaust Hood Ducting page.

Before starting production, the operator must check that all covers and guards are in place, no material has been left

on the conveyor, and the work area is clear of obstructions.

Switch on and verify conveyor belt is moving before turning on the heat.

Allow dryer to cool to 300°F (149°C) before switching off conveyor.

Always turn off power at the main disconnect at the end of production.

In case an abnormal symptom occurs, for example excessive vibration, noise, and strong smell or smoke develop-

ment, turn off the VASTEX Conveyor Curing System and contact a qualified technician.

Immediately turn off the VASTEX Conveyor Curing System if products become jammed in the drying chamber or

conveyor belt.

Do not remove any cover or guard until power at the main disconnect is switched off and locked out. No unauthor-

ized persons are to be allowed inside the control boxes.

Turn off and lock out power at the main disconnect before any cleaning or maintenance.

Only qualified technicians should be allowed to make repairs on the VASTEX Conveyor Curing System.

Noise and vibration: This equipment does not produce noise exceeding 70 dB(A) at workstations.

CE Declaration of Conformity available upon request.

Stability during use, transportation, assembly, dismantling when out of service, testing, and foreseeable

breakdowns: This equipment is designed and expected to be stable during all foreseeable conditions, so long as

the procedures and instructions given in this manual are followed.

Safe handling, transport, and storage: Before storing the unit, follow the shutdown procedure on Pg.11 (or on the

front of your machine) to allow the heater assembly to cool properly. No special handling considerations are neces-

sary, except to be aware of the weight of the equipment and take standard precautions for moving such weights:

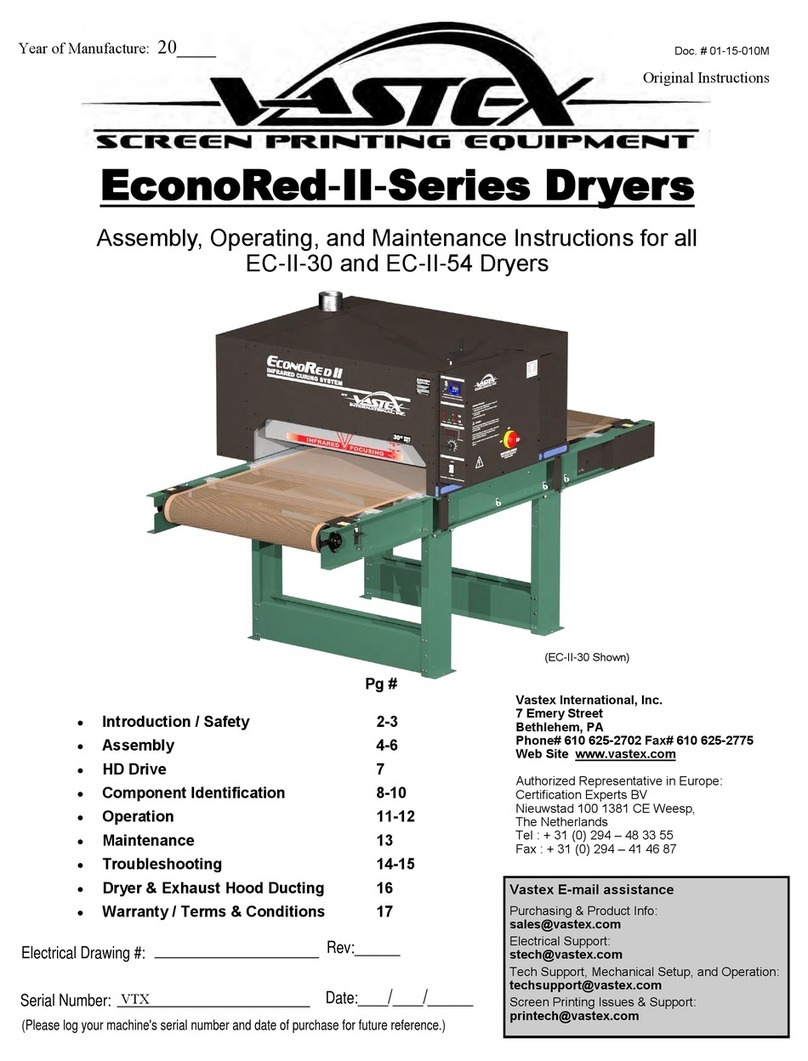

ER-II-30: 350 lbs (159 kg), 87” x 49” x 53” (221 cm x 124 cm x 135 cm)

ER-II-54: 650 lbs (295 kg), 87” x 73.5” x 53” (221 cm x 187 cm x 135 cm)

ER-III-30: 550 lbs (250 kg), 106” x 49” x 53” (269 cm x 124 cm x 135 cm)

ER-III-54: 850 lbs (386 kg), 106” x 73.5” x 53” (269 cm x 187 cm x 135 cm)

Placing your equipment into service and using your machine:

To place your machine into service:

-Read and understand Component Identification, Controls, Operation, and Safety pages.

-Follow Assembly pages before powering up machine

To use your machine, follow the instructions found in Operation.

Safety, continued

Important