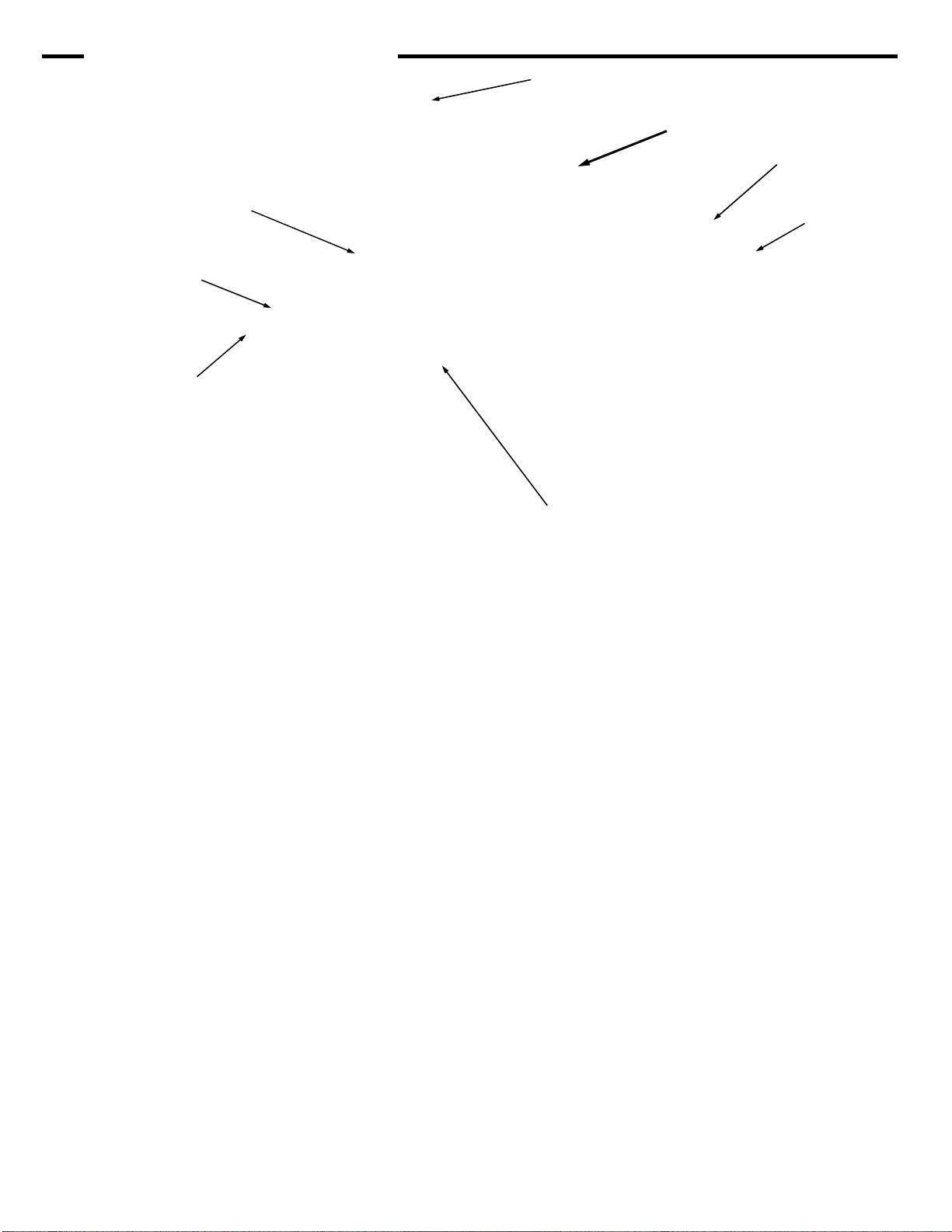

DC Volt Meter:

Digital Volt Meter displays, in

volts, the amount of power going

to the belt motor. A table showing

the time associated with voltage

can be found in Dryer Operation.

Belt Speed Control: An AC-DC

converter, mounted to the face of the

control panel, allows the operator to

vary the belt speed / DC volts to the

motor. The dial is for reference only and

does not represent seconds in the heat.

Control Output Light:

This light should cycle on & off

with the controller, indicating

output signal to relay.

(1 light per temp control)

System Switch:

Sends power to Controls.

Shut off power at main dis-

connect before servicing,

Power Light must be out be-

fore entering any part of this

machine

Power Light: It is wired to

the line cord and/or the Shut

Off Switch and will be

illuminated whenever power

is coming into the unit. At the

end of the day, the machine

should be disconnected so

this light is out.

Temperature Control:

See Dryer Operation

for more information

(1 control per zone)

Relay Output Light:

This 250 volt RED pilot light

is wired to the output side of

the relay. This light will cycle

on & off with the control

output light. It verifies that

the relay is working properly.

(1 light per relay)

Heat Switch:

Controls power

to heater only.

Controls (LittleRed X1/X2/X3)

Shut Off Switch

Machines that are direct wired by the end user are

equipped with a shutoff switch. This is the main junction

block for incoming power, and is used to restrict access

to the control box while it is live. The shutoff must be in

the OFF position to enter the control box.

Shut Off Switch:

Fuses:

Fuses for control circuit

are located on the face for

easy maintenance. Older

models have fuses located

inside the control box.

Please refer to wiring

diagram for fuse specs.

Heater Light:

This 6v WHITE pilot light is

wired to the IR Heaters. These

lights indicate when electricity

is flowing through each heater.

(1 light per heater)

Controls (LittleRed X1D-18)

Heat Switch: Main Heat Switch

controls power to heater.

Boost Zone Diagnostics:

The Boost Zone on your X1D is always

active. These 2 lights should stay on while

the Heat Switch is on and the Boost Zone

is functioning. BOOST mode runs the front

19% of the heater at 100% power to

preheat the garment on tunnel entry.