2Vector Lab Products Refrigerators and Freezers

Contents

Welcome to Vector ............................................................................. 3

Before you begin............................................................................... 3

Ambients ..................................................................................... 4

Clearances ................................................................................... 4

Electrical Specications......................................................................... 4

Refrigeration Specications ..................................................................... 4

Installation .................................................................................... 5

Install shelves (if equipped) and power up......................................................... 5

Power the Unit .............................................................................. 5

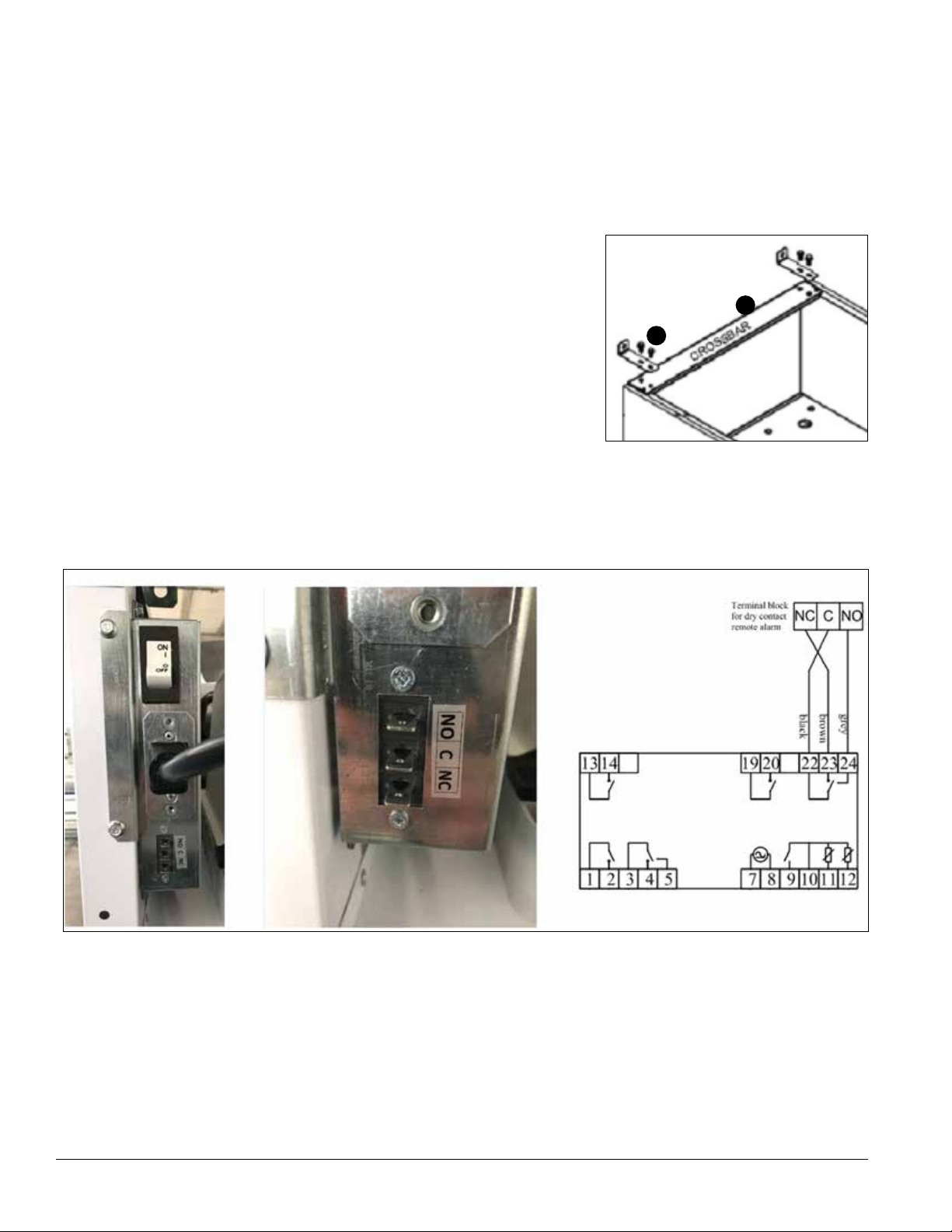

Stabilizer Bracket Details ...................................................................... 6

Remote Alarm Connection ..................................................................... 6

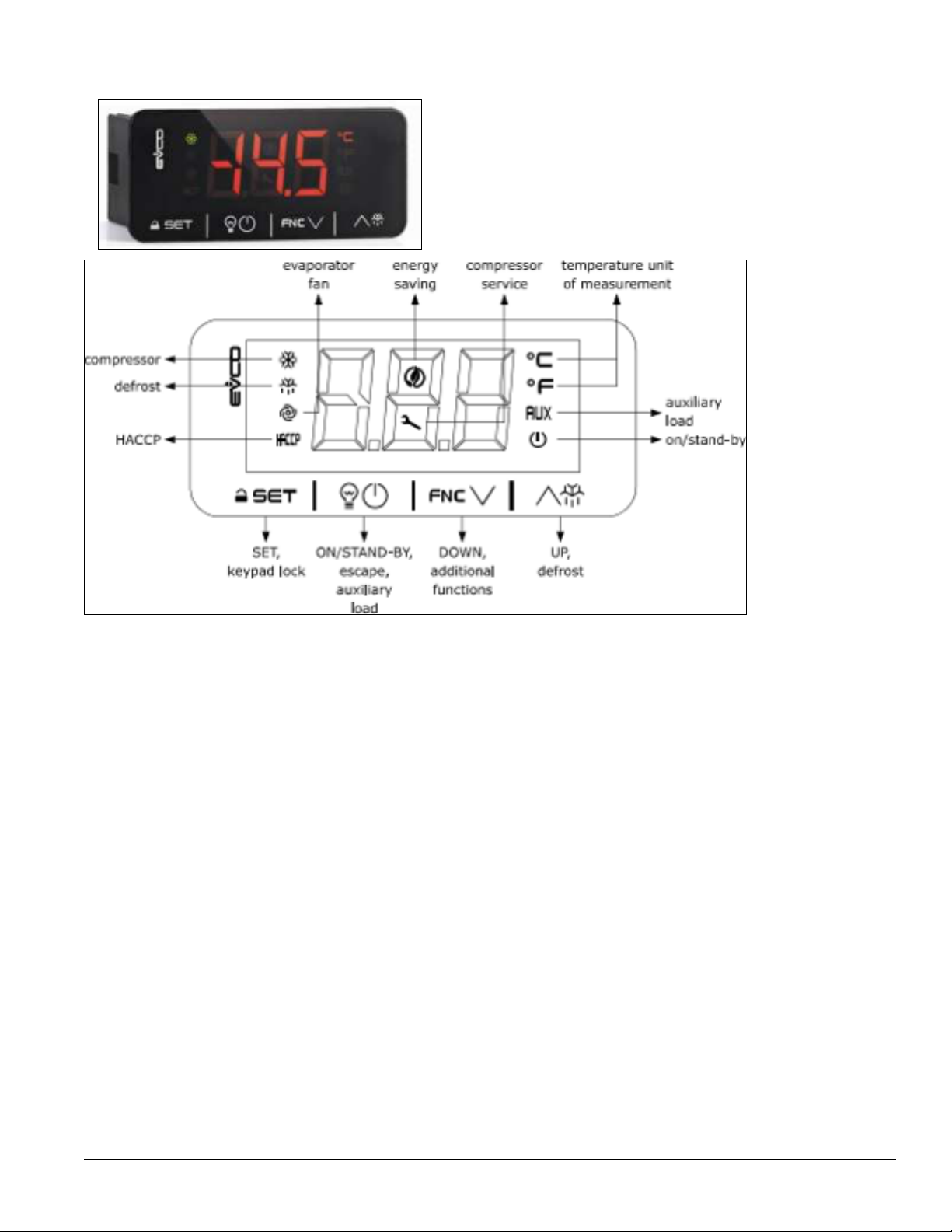

Controller Operation ........................................................................... 7

Locking/Unlocking of the Keypad ................................................................ 8

Viewing/Adjusting the Set Point ................................................................. 8

Powering the Equipment ON.................................................................... 8

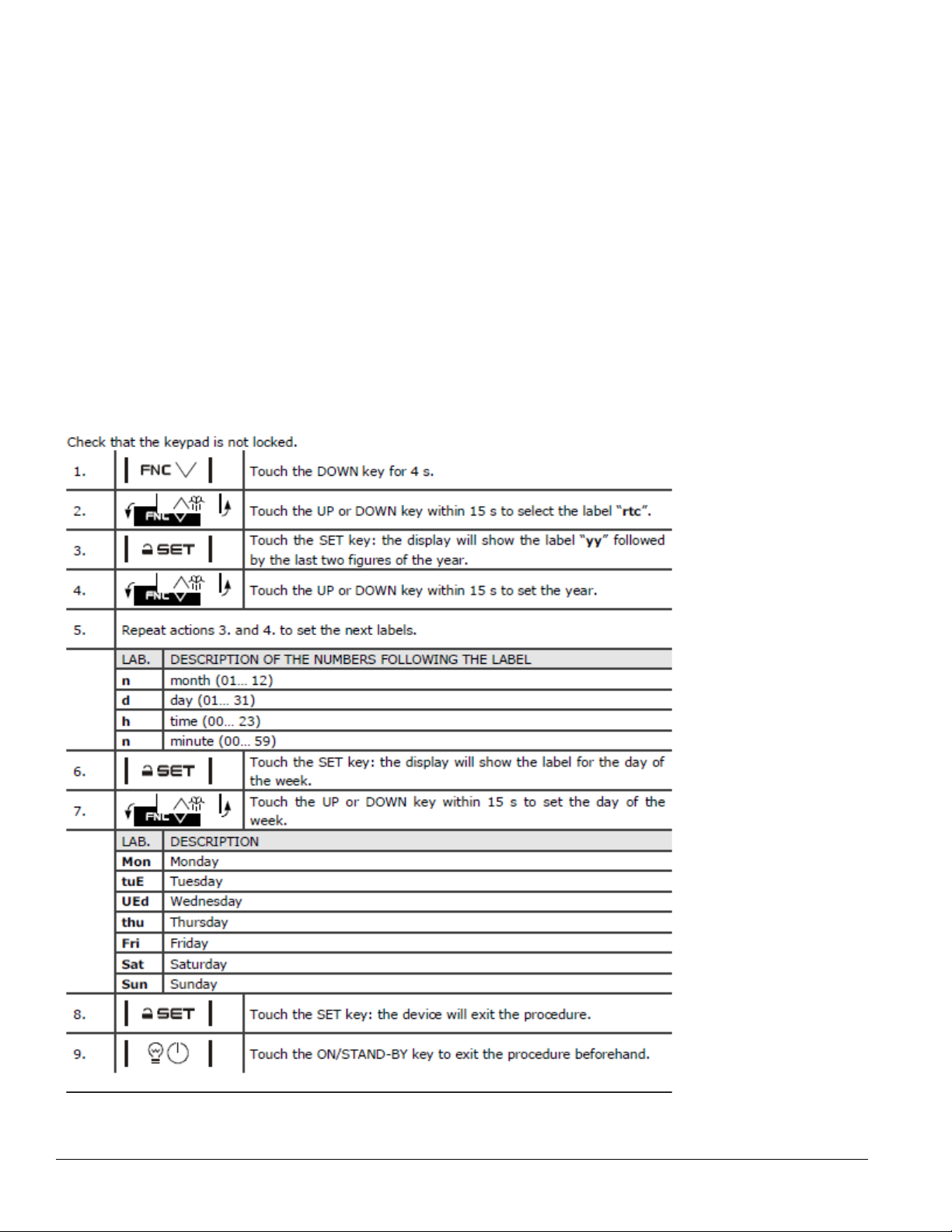

Controller Set Up ............................................................................ 8

Defrosting .................................................................................. 9

Door Switch ................................................................................ 9

Cleaning ......................................................................................11

Interior Cleaning .............................................................................11

Exterior Cleaning ............................................................................11

Annual Cleaning ............................................................................11

Refrigeration System .........................................................................11

Refrigeration Diagram - Refrigerators............................................................. 12

Refrigeration Diagram - Freezers................................................................. 12

Facade Removal .............................................................................. 13

Controller Replacement ........................................................................ 13

Door Gasket Replacement ...................................................................... 14

Modular Refrigeration System ................................................................... 14

Wiring Diagram - Glass Door.................................................................... 15

Wiring diagram - Solid Door .................................................................... 16