2

Contents

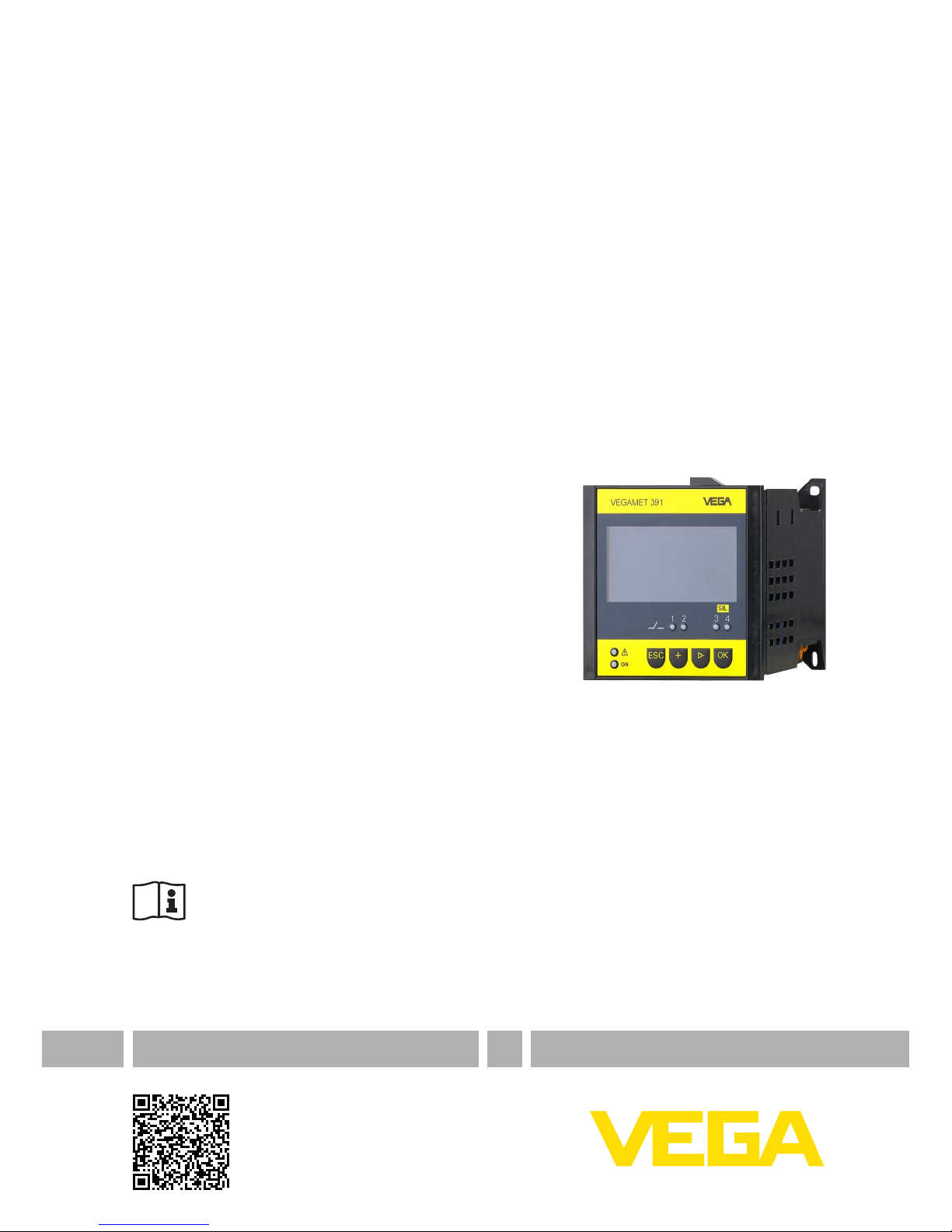

VEGAMET 391 • With SIL qualication

38704-EN-170907

Contents

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Safety label on the instrument .......................................................................................... 6

2.6 EU conformity................................................................................................................... 6

2.7 SIL conformity .................................................................................................................. 6

2.8 Installation and operation in the USA and Canada ........................................................... 6

2.9 Safety instructions for Ex areas ........................................................................................ 6

2.10 Environmental instructions ............................................................................................... 7

3 Product description ................................................................................................................. 8

3.1 Conguration.................................................................................................................... 8

3.2 Principle of operation........................................................................................................ 9

3.3 Adjustment ....................................................................................................................... 9

3.4 Packaging, transport and storage................................................................................... 10

4 Mounting................................................................................................................................. 11

4.1 General instructions ....................................................................................................... 11

4.2 Mounting instructions ..................................................................................................... 11

5 Connecting to power supply................................................................................................. 14

5.1 Preparing the connection ............................................................................................... 14

5.2 Connection procedure.................................................................................................... 14

5.3 Wiring plan ..................................................................................................................... 16

6 Functional safety (SIL) .......................................................................................................... 17

6.1 Directive and scope........................................................................................................ 17

6.2 SIL qualication.............................................................................................................. 17

6.3 Application area ............................................................................................................. 17

6.4 Safety concept of the parameterization .......................................................................... 18

7 Setup with the integrated display and adjustment unit ..................................................... 20

7.1 Adjustment system......................................................................................................... 20

7.2 Setup steps .................................................................................................................... 21

7.3 Menu schematic............................................................................................................. 30

8 Setup with PACTware............................................................................................................. 36

8.1 Connect the PC.............................................................................................................. 36

8.2 Parameter adjustment with PACTware............................................................................ 36

9 Application examples ............................................................................................................ 38

9.1 Overll protection according to SIL................................................................................. 38

9.2 Dry run protection according to SIL2 .............................................................................. 39

9.3 Pump control 1/2 (run time controlled)............................................................................ 41

10 Maintenanceandfaultrectication...................................................................................... 44