2

Contents

VEGASWING 66 • Relay (2 x SPDT)

45307-EN-180717

Contents

1 Document language ................................................................................................................ 3

2 Scope ........................................................................................................................................ 4

2.1 Instrument version............................................................................................................ 4

2.2 Area of application ........................................................................................................... 4

2.3 SIL conformity .................................................................................................................. 4

3 Planning.................................................................................................................................... 5

3.1 Safety function ................................................................................................................. 5

3.2 Safe state ......................................................................................................................... 5

3.3 Prerequisites for operation ............................................................................................... 5

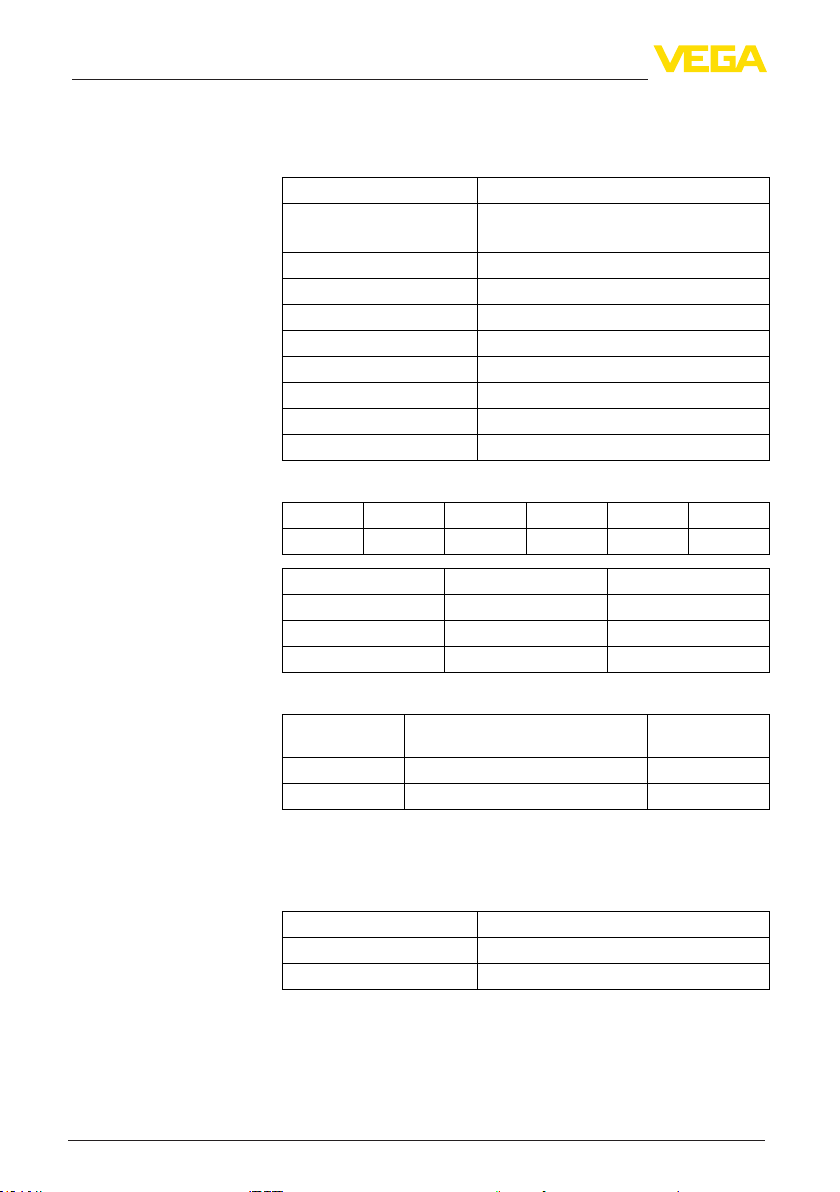

4 Safety-related characteristics................................................................................................. 6

4.1 Characteristics acc. to IEC 61508 .................................................................................... 6

4.2 Characteristics acc. to ISO 13849-1................................................................................. 6

4.3 Supplementary information .............................................................................................. 7

5 Setup ......................................................................................................................................... 9

5.1 General information.......................................................................................................... 9

5.2 Adjustment instructions .................................................................................................... 9

6 Diagnostics and servicing .................................................................................................... 10

6.1 Behaviour in case of failure ............................................................................................ 10

6.2 Repair ............................................................................................................................ 10

7 Proof test ................................................................................................................................ 11

7.1 General information........................................................................................................ 11

7.2 Test1:Withoutllingordismountingthesensor............................................................. 11

7.3 Test2:Withllingordismountingofthesensor .............................................................. 12

8 Appendix A: Test report......................................................................................................... 13

9 AppendixB:Termdenitions................................................................................................ 14

10 Supplement C: SIL conformity.............................................................................................. 15

Editingstatus:2018-07-17