Contents

Chapter 1 Safety Information and Precautions.......................................................................................... 1

1.1 Safety Precautions........................................................................................................................... 1

1.2 Precaution ......................................................................................................................................... 2

Chapter 2 Product Information ..................................................................................................................... 4

2.1 Designation Rules............................................................................................................................ 4

2.2 Product series instruction ............................................................................................................... 4

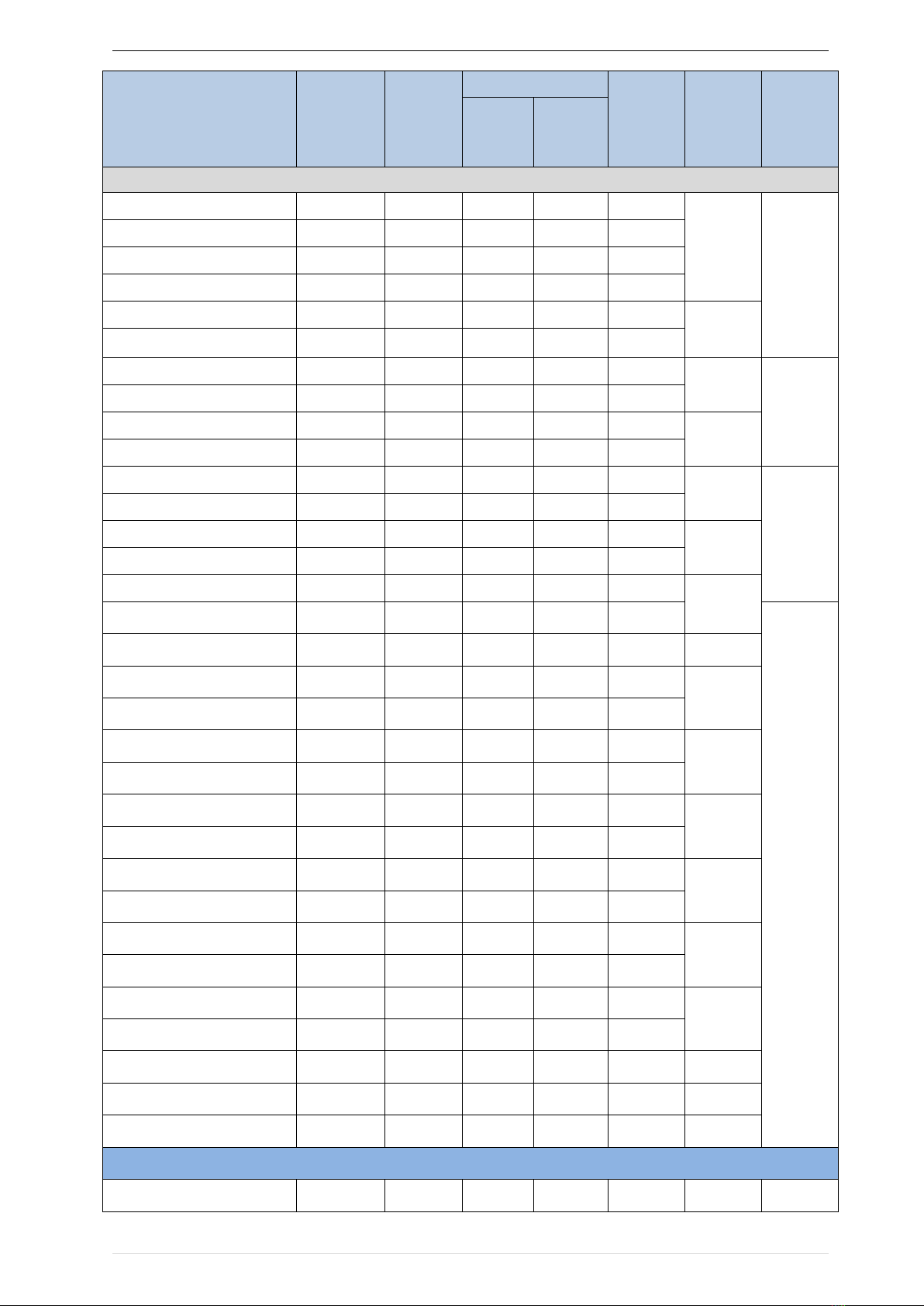

2.3 Technical Specifications.................................................................................................................. 6

Chapter 3 Product appearance and Installation Dimension .............................................................. 9

3.1 Product appearance and installation............................................................................................. 9

3.1.1 Product appearance............................................................................................................. 9

3.1.2 Appearance and Mounting Hole Dimension ................................................................... 12

3.1.3 Removal and installation of cover and inlet plate .......................................................... 17

3.2 Wiring............................................................................................................................................... 20

3.2.1 Standard wiring diagram.................................................................................................... 20

3.2.2 Main Circuit Terminals........................................................................................................ 21

3.2.3 Terminal screws and wiring specifications ...................................................................... 22

3.2.4 Cautions for Main Circuit Wiring....................................................................................... 24

3.2.5 Control Circuit Terminal ..................................................................................................... 25

3.3 EMCquestion and solution............................................................................................................ 31

Chapter 4 Operation and display ............................................................................................................... 33

4.1 LED Instruction of operation and display ................................................................................... 33

4.2 Display hierarchy and menu mode.............................................................................................. 34

4.3 Digital tube display......................................................................................................................... 35

4.4 Test run............................................................................................................................................ 36

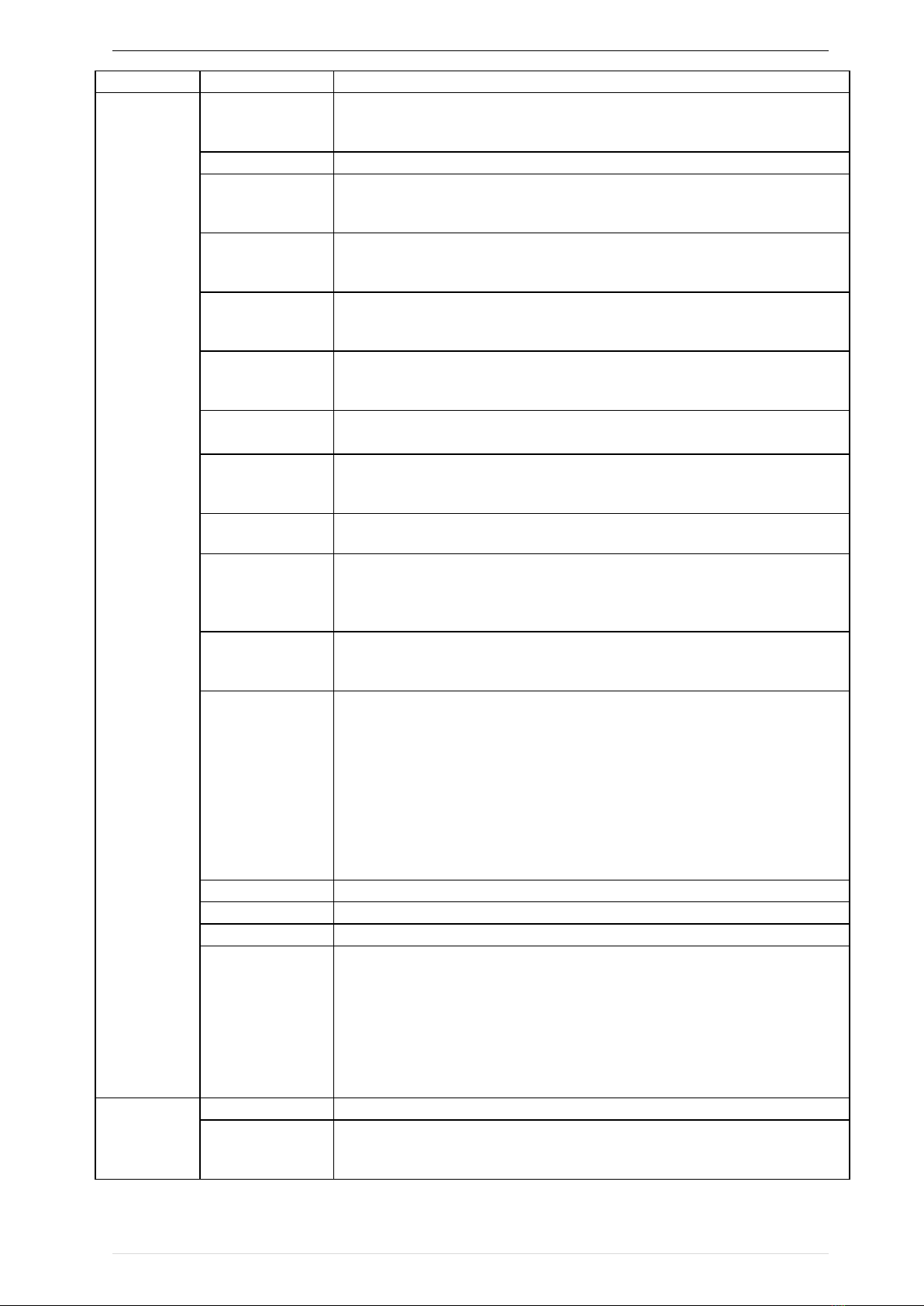

Chapter 5 Function Code Table.................................................................................................................. 38

Chapter 6 Fault Diagnosis and Solution ................................................................................................. 122

6.1 Failure and diagnosis .................................................................................................................. 122

6.2 Warning type................................................................................................................................. 128

Chapter 7 Selection Guide of inverter Accessory.................................................................................. 130

7.1 Selection Guide of braking component..................................................................................... 130

7.2 PG card type................................................................................................................................. 131

7.3 IO Extension card ........................................................................................................................ 134

7.4 CANopen exentsion card............................................................................................................ 136

Chapter 8 Daily maintenance of frequency inverters............................................................................ 139

8.1 Daily maintenance ....................................................................................................................... 139

8.1.1 Daily maintenance ............................................................................................................ 139

8.1.2 Regular inspection............................................................................................................ 139

8.2 Wearing parts replacement ........................................................................................................ 139

8.3 Warranty Items ............................................................................................................................. 140

Appendix A Modbus communication protocol ..................................................................................... 141