_______________________________________________________________________________________________________________________________________________________

8

17. ASSEMBLY, HOOK-UP AND USE

Assembly :

The 12-position rotary switch SW3 must be configured for 8 positions.

Turn the switch all the way counterclockwise.

Remove the nut and the lockwasher

Lift the stop washer and move it to position ‘8’

Put the lockwasher and nut back in place

Take care when connecting and using this kit. Most parts carry lethal volt-

ages. All wires of the output section must be at least 2.5mm² (14AWG).

Power supply wiring can be done with 0.5mm² (22AWG) wire. Use fuse rat-

ings as indicated on the connection examples.

Put an extra layer of solder on all thinned PCB tracks, to improve their cur-

rent handling capabilities. This unit is suitable for use with resistive loads,

such as regular incandescent lightbulbs. The unit is not suitable for use with

transformer operated lighting or fluorescent lighting.

Hook-up of one unit :

Hook-up the unit as shown in the diagram.

To use the internal speed adjustment, connect ‘OSC OUT’with ‘SIG IN’by

means of a wire jumper. A external 5V CMOS clock signal (e.g generated

by a beat detector), can be connected between GND and SIG. IN.

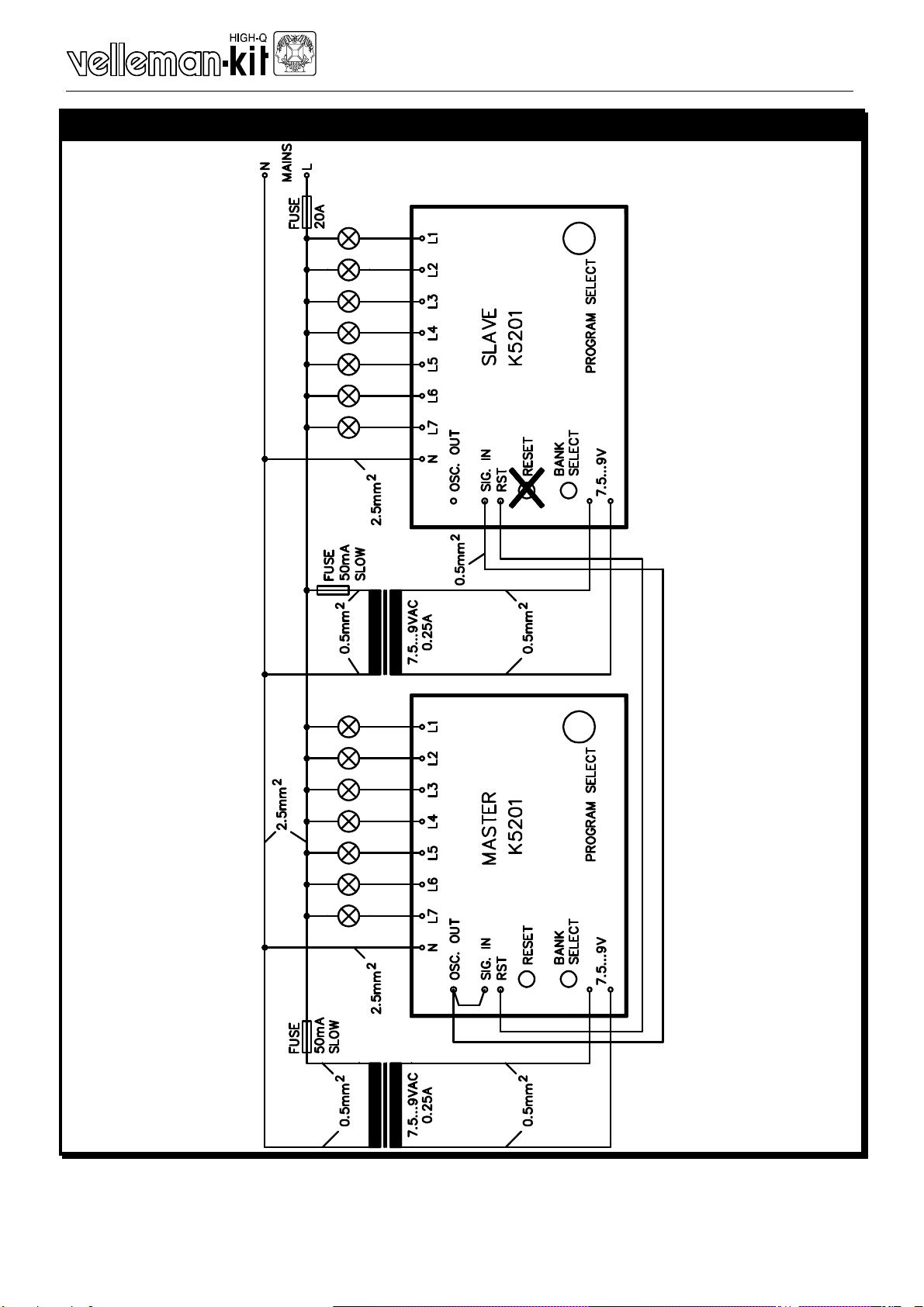

Cascading of two units :

Two units can be hooked-up in cascade configuration, to create a 14 -

channel lightshow. Hook-up both units as shown in the diagram. The ‘RE-

SET’button of the slave unit can be omitted. It is very important that each

unit gets its own power supply transformer. Do not use a single transformer

for both units. Make sure the ‘L’(live) of both kits is connected to the same

phase of the mains. Not doing so will result in damage beyond repair of

both kits, and the risk of fire. Use 4mm² (12AWG) wire for the output sec-

tion and use fuses rated as indicated.

Patterns 15 and 16 have been developed for cascade use. Choose pattern

15 for the master unit, and pattern 16 for the slave unit.

Use :

Choose between 8 different patterns with the rotary switch SW3.

SW2 allows selection of another bank of 8 patterns.

To restart the selected pattern, press ‘RESET’

If internal speed control has been chosen (OSC. OUT connected to SIG.

IN), you can adjust the running speed with RV1.