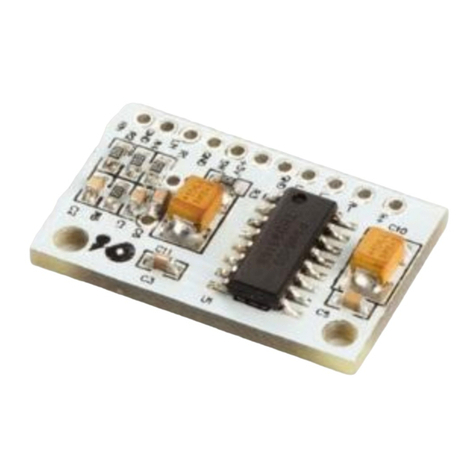

Velleman K8040 User manual

Other manuals for K8040

1

Other Velleman Amplifier manuals

Velleman

Velleman K8060 User manual

Velleman

Velleman High-Q Velleman-kit K8022 User manual

Velleman

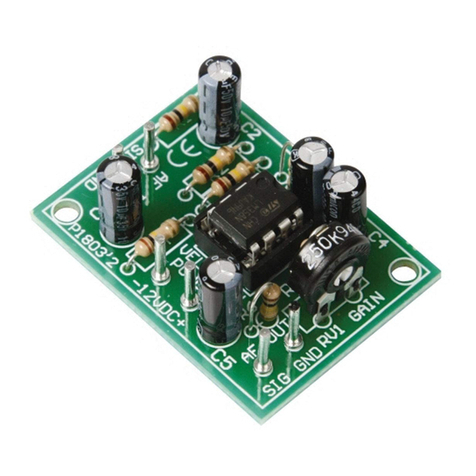

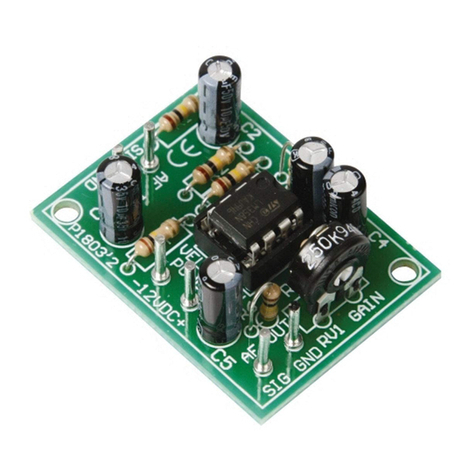

Velleman K1803 User manual

Velleman

Velleman 8021 User manual

Velleman

Velleman HQ Power PA100U User manual

Velleman

Velleman VPA2100M User manual

Velleman

Velleman 8040 User manual

Velleman

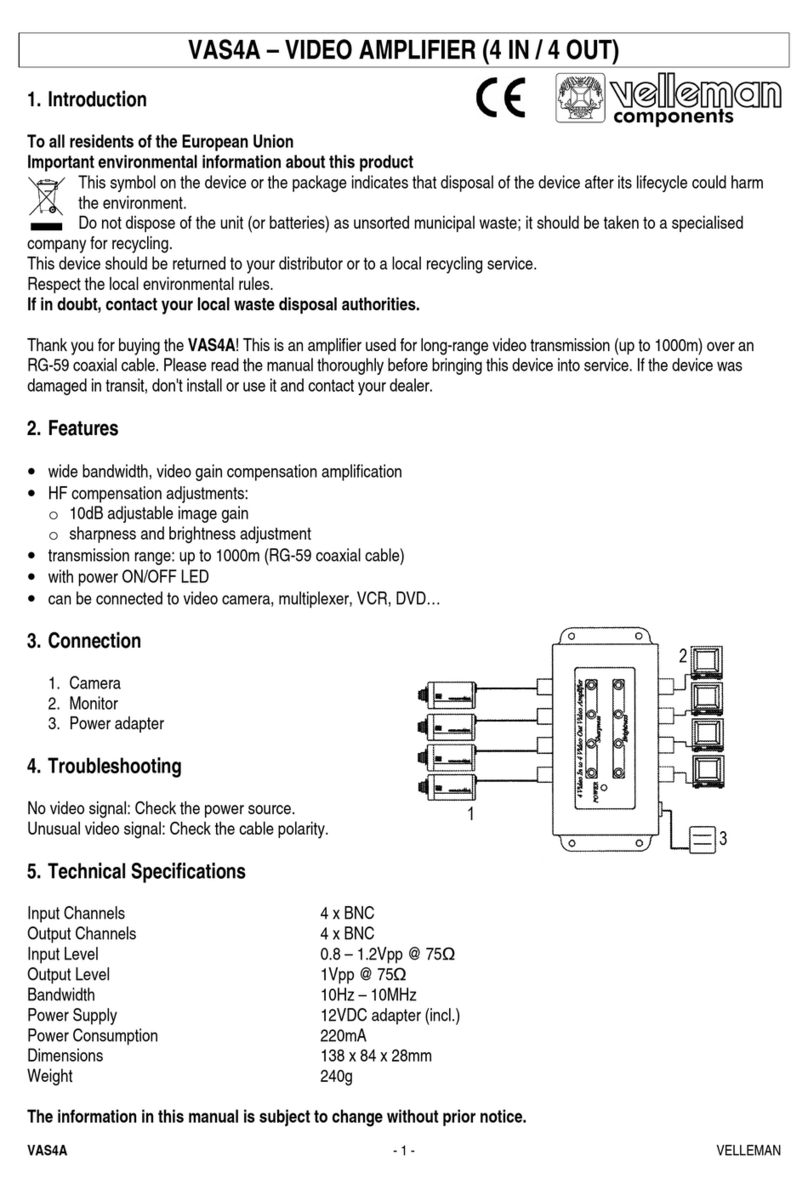

Velleman VAS4A User manual

Velleman

Velleman HQ Power PA100U User manual

Velleman

Velleman HQ-POWER SAGIRA 100 User manual

Velleman

Velleman K4001 User manual

Velleman

Velleman HQ-Power ANTM7 User manual

Velleman

Velleman High-Q Kit K1803 User manual

Velleman

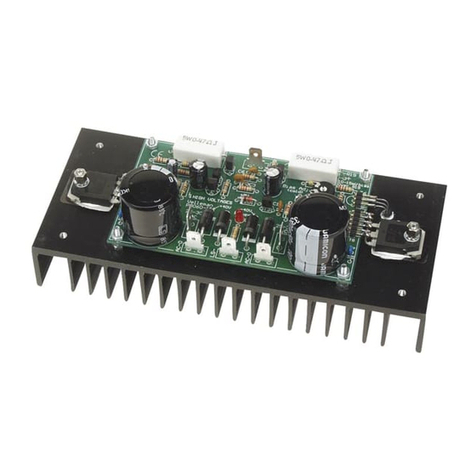

Velleman K4040 User manual

Velleman

Velleman HQ Power VPA2350MB User manual

Velleman

Velleman VM100 User manual

Velleman

Velleman HQ Power ONELINER 200 User manual

Velleman

Velleman K4005B User manual

Velleman

Velleman K8021 User manual

Velleman

Velleman K8010 User manual