Velleman K8077 User manual

Total solder points: 383

Difficulty level: beginner 1 2 3 4 5 ⌧advanced

100W SUBWOOFER KIT

ILLUSTRATED ASSEMBLY MANUAL H8077IP-1

Powerful bassfromasmallcabinetthanksto

thedualspeakerprinciple

K8077

K8077

2

Features & specifications

Features :

bass-reflex system with adjustable tube

compact size due to dual-speaker principle

adjustable level and filter response

auto power-on/off system

phase switch (0°-180°)

line level and speaker level inputs for maximum compatibility

'Full-range'-option for use in active speaker system

separate chamber for electronics avoids air leaks

Specifications

• power output: 100Wrms/ 4ohm (10% THD)

• filter freq. response:

wide: 25 - 110Hz (-6dB)

narrow: 18 - 65Hz (-6dB)

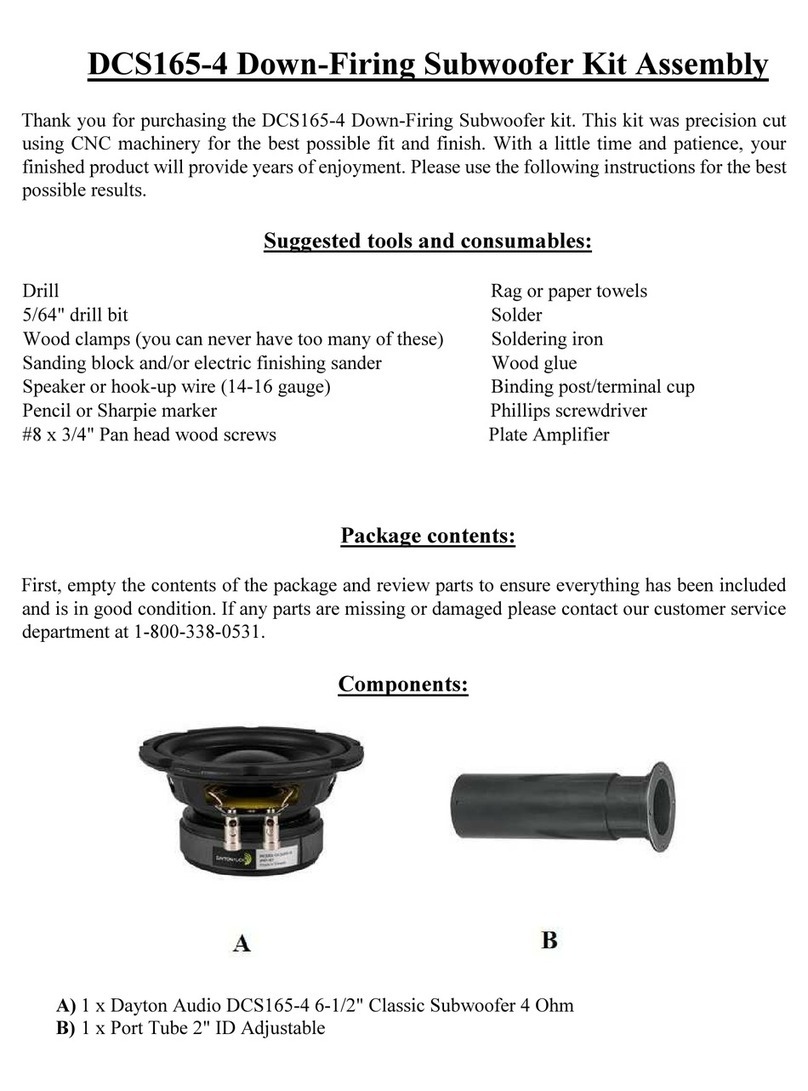

• speakers: two 6.5" 8 ohm drivers

• line level input sensitivity: 500mV

• auto turn-on level: 5mV

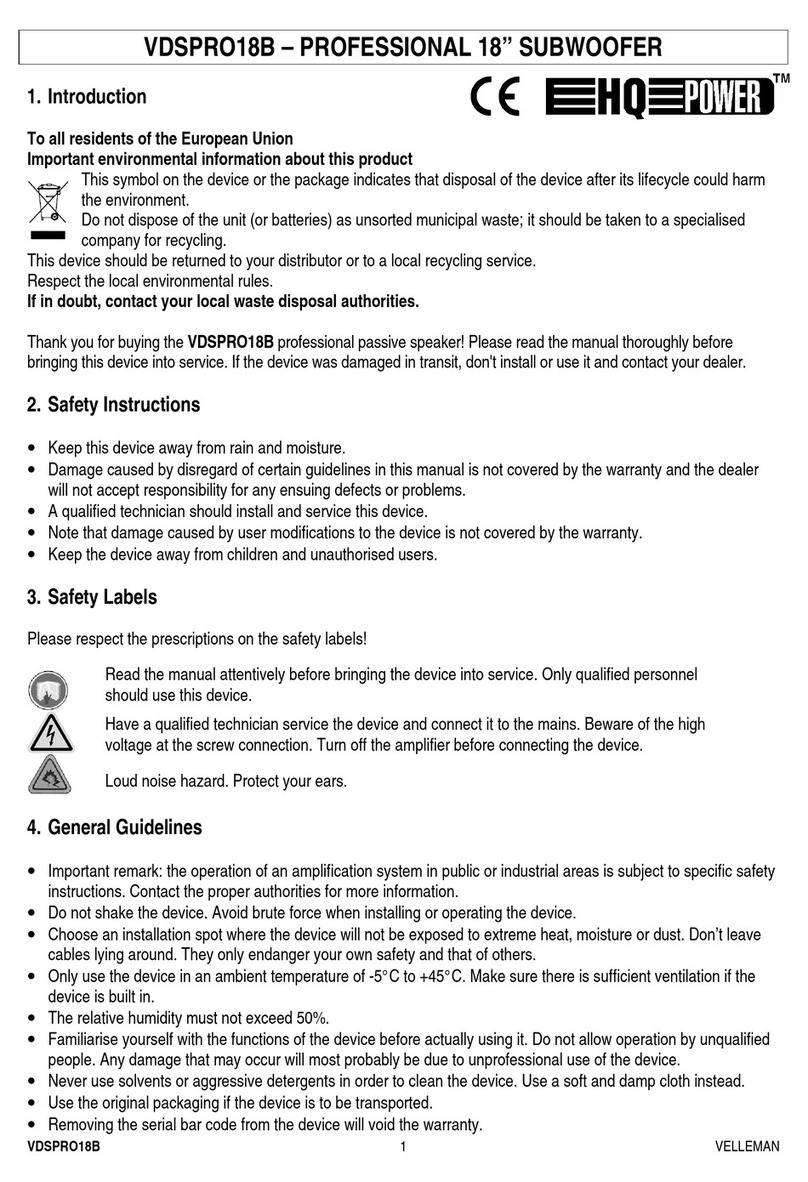

• volume*: approx. 20 liter

• power supply: 120/230VAC

• dimensions*: 460x310x210mm / 18,22 x 12,28 x 8,32"

(*) recommended enclosure. Drawings for enclosure are included

3

Assembly hints

1. Assembly (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project

successful. Read them carefully.

1.1 Make sure you have the right tools:

• A good quality soldering iron (25-40W) with a

small tip.

• Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to

the tip, to give it a wet look. This is called ‘thinning’ and will protect

the tip, and enables you to make good connections. When solder

rolls off the tip, it needs cleaning.

• Thin raisin-core solder. Do not use any flux or grease.

• A diagonal cutter to trim excess wires. To avoid injury when cutting

excess leads, hold the lead so they cannot fly towards the eyes.

• Needle nose pliers, for bending leads, or to hold compo-

nents in place.

• Small blade and Phillips screwdrivers. A basic range

is fine.

For some projects, a basic multi-meter is required, or might

be handy

1.2 Assembly Hints :

⇒Make sure the skill level matches your experience, to avoid disappointments.

⇒Follow the instructions carefully. Read and understand the entire step before

you perform each operation.

⇒Perform the assembly in the correct order as stated in this manual

⇒Position all parts on the PCB (Printed Circuit Board) as shown on the draw-

ings.

⇒Values on the circuit diagram are subject to changes.

⇒Values in this assembly guide are correct*

0.000

4

⇒Use the check-boxes to mark your progress.

⇒Please read the included information on safety and customer service

* Typographical inaccuracies excluded. Always look for possible last minute

manual updates, indicated as ‘NOTE’ on a separate leaflet.

1.3 Soldering Hints :

1- Mount the component against the PCB sur-

face and carefully solder the leads

2- Make sure the solder joints are cone-shaped

and shiny

3- Trim excess leads as close as possible to the

solder joint

REMOVE THEM FROM THE TAPE ONE AT

A TIME !

Assembly hints

AXIAL COMPONENTS ARE TAPED IN

THE CORRECT MOUNTING SEQUENCE !

5

Construction

R1 : 22K (2 - 2 - 3 - B)

R2 : 22K (2 - 2 - 3 - B)

R7 : 47K (4 - 7 - 3 - B)

R12 : 22K (2 - 2 - 3 - B)

R13 : 22K (2 - 2 - 3 - B)

R14 : 33K (3 - 3 - 3 - B)

R15 : 22K (2 - 2 - 3 - B)

R16 : 10K (1 - 0 - 3 - B)

R17 : 22K (2 - 2 - 3 - B)

R18 : 1K (1 - 0 - 2 - B)

R19 : 10K (1 - 0 - 3 - B)

R20 : 1K (1 - 0 - 2 - B)

R21 : 1M (1 - 0 - 5 - B)

R22 : 33K (3 - 3 - 3 - B)

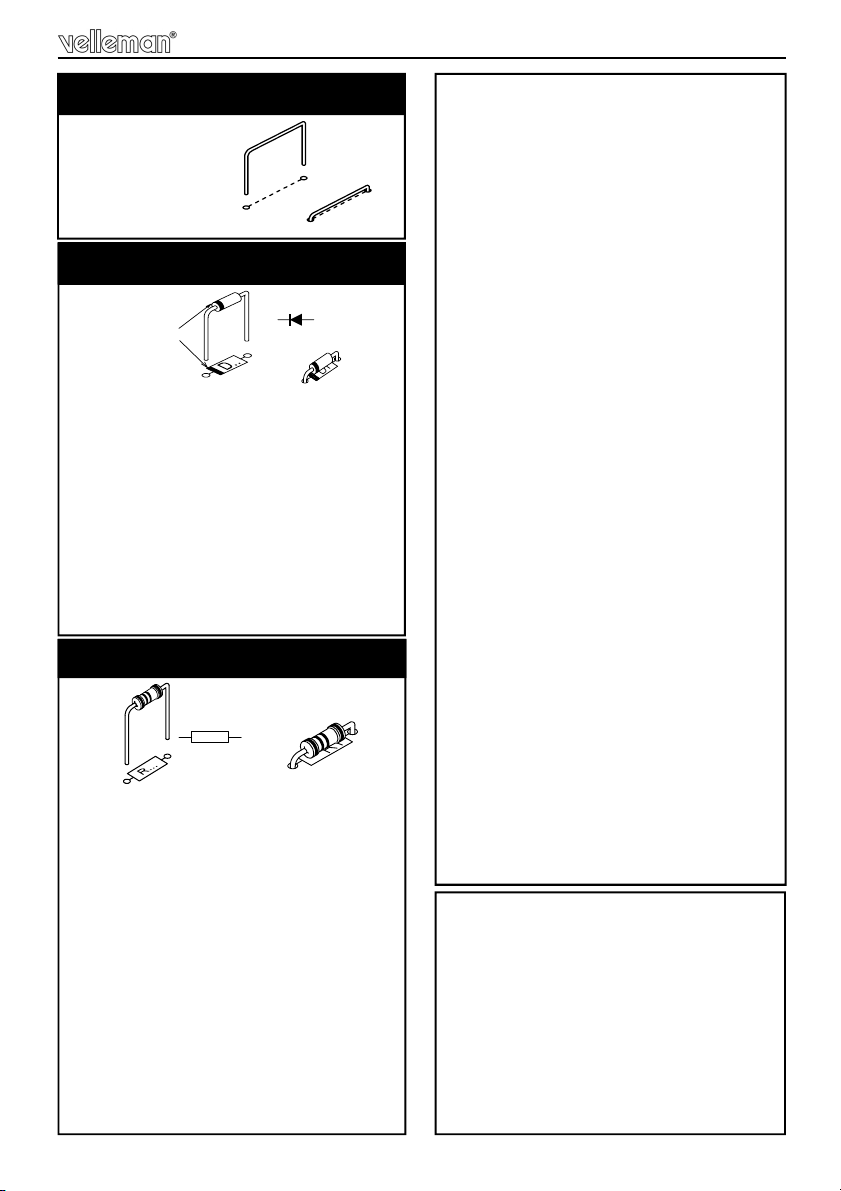

3. 1/4W resistors.

R...

J1 … J8

R3

R4

R8

R11

1. Jump wires.

D1 : BAT85

D2 : 1N4148

D3 : 1N4148

D4 : 1N4148

D5 : 1N4007

D6 : 1N4007

D7 : 1N4007

D8 : 1N4007

D9 : 1N4007

D10 : 1N4007

2. Diodes (check the polarity)

CATHODE

D...

R23 : 1K (1 - 0 - 2 - B) *

R24 : 100K (1 - 0 - 4 - B)

R25 : 390K (3 - 9 - 4 - B)

R26 : 15K (1 - 5 - 3 - B)

R27 : 470 (4 - 7 - 1 - B)

R28 : 15K (1 - 5 - 3 - B)

R29 : 100K (1 - 0 - 4 - B)

R30 : 100K (1 - 0 - 4 - B)

R34 : 10K (1 - 0 - 3 - B)

R35 : 10K (1 - 0 - 3 - B)

R36 : 10K (1 - 0 - 3 - B)

R37 : 10K (1 - 0 - 3 - B)

R39 : 10K (1 - 0 - 3 - B)

R40 : 100K (1 - 0 - 4 - B)

R41 : 33K (3 - 3 - 3 - B)

R42 : 100 (1 - 0 - 1 - B)

R43 : 47K (4 - 7 - 3 - B)

R44 : 330 (3 - 3 - 1 - B)

R45 : 220 (2 - 2 - 1 - B)

R46 : 47 (4 - 7 - 0 - B)

R47 : 3K3 (3 - 3 - 2 - B)

R48 : 680 (6 - 8 - 1 - B)

R49 : 3K3 (3 - 3 - 2 - B)

R50 : 3K3 (3 - 3 - 2 - B)

R51 : 10 (1 - 0 - 0 - B)

R52 : 3K3 (3 - 3 - 2 - B)

R53 : 1K5 (1 - 5 - 2 - B)

R54 : 3K3 (3 - 3 - 2 - B)

R55 : 680 (6 - 8 - 1 - B)

R56 : 1K (1 - 0 - 2 - B)

R57 : 220 (2 - 2 - 1 - B)

R58 : 47 (4 - 7 - 0 - B)

R61 : 1K8 (1 - 8 - 2 - B)*

R62 : 470 (4 - 7 - 1 - B)

(*) Select operation mode :

Subwoofer:

R61 : not mounted

R23 : 1K

Full range:

R61 : 1K8

R23 : not mounted

Full range with 6dB bass boost:

R61 : 1K8

R23 : 1K

6

R5 : 100 (1 - 0 - 1 - B - 9)

R6 : 470 (4 - 7 - 1 - B - 9)

R9 : 100 (1 - 0 - 1 - B - 9)

R10 : 470 (4 - 7 - 1 - B - 9)

R31 : 820 (8 - 2 - 1 - B)

R32 : 820 (8 - 2 - 1 - B)

R33 : 560 (5 - 6 - 1 - B)

R38 : 2K7 (2 - 7 - 2 - B - 9)

Construction

ZD1 : 5V1

ZD2 : 5V1

ZD3 : 15V0

ZD4 : 15V0

ZD5 : 9V1

5. Zener diodes (check the polarity)

CATHODE

ZD...

IC1 : 8p

IC2 : 14p

IC3 : 8p

8. IC sockets. Watch the position

of the notch!

C1 : 390pF (391)

C2 : 390pF (391)

C3 : 100nF (104)

C4 : 100nF (104)

C5 : 100nF (104)

C6 : 100nF (104)

C7 : 100nF (104)

C8 : 100nF (104)

C9 : 100nF (104)

C10 : 100nF (104)

C11 : 680pF (680)

C12 : 680pF (680)

C13 : 47nF (473)

C14 : 47pF (47)

C15 : 47pF (47)

C16 : 47pF (47)

C17 : 1nF (102)

C18 : 100pF (101)

C19 : 10nF (103)

9. Capacitors

c...

LD3 : RED (-35/+35VDC)

7. LEDs. Watch the polarity!

LD1

CATHODE

4. Metallfilm resistors.

R...

T7 : 5 pins

T8 : 6 pins

T9 : 6 pins

6. Pinheaders

7

Construction

D11 : 1N5404

D12 : 1N5404

D13 : 1N5404

D14 : 1N5404

10. Diodes (check the polarity)

CATHODE

C20 : 0,047µF / 63V

C21 : 0,068µF / 63V

C22 : 4700pF/ 100V

C23 : 0,022µF / 63V

C24 : 0,022µF / 63V

RV3 : 1K

Turn RV3 fully

counter-

clockwise

11. Trim potentiometer

R4

T1 : BC547B

T2 : BC547B

T3 : BC640

T4 : BC640

T5 : BC557

T6 : BC639

12. Transistors

T1

R59 : 0,47

R60 : 0,47

13. 5W resistors

R...

2mm

SK12 : GND

14. PCB tab

LS+

LS-

AC BLUE

AC RED

AC GREY

AC YELLOW

15. Flat receptacles

SK...

SK11

Remark: if you wish to have a

‘POWER’ and ‘ON’ indication in a

remote location, you can remove the

shunts and connect the supplied fe-

male board to wire connector and two

extra LED’s

16. Male board wire connector

SK11

SK11

-

-

+

+

+

-

+

-

SK11 +

-

+

-

D...

Wiring diagram:

Brown cathode1 ON

Red anode1

Orange anode2

Yellow cathode2

POWER

SK11 +

-

+

-

Cathode2

Cathode1

Anode1

Brown

Red

Orange

Yellow

Anode2

8

C25 … C28 : 10µF / 35V

C29 : 22µF / 50V

C30 … C35 : 100µF / 50V

C36 : 470µF / 16V

construction

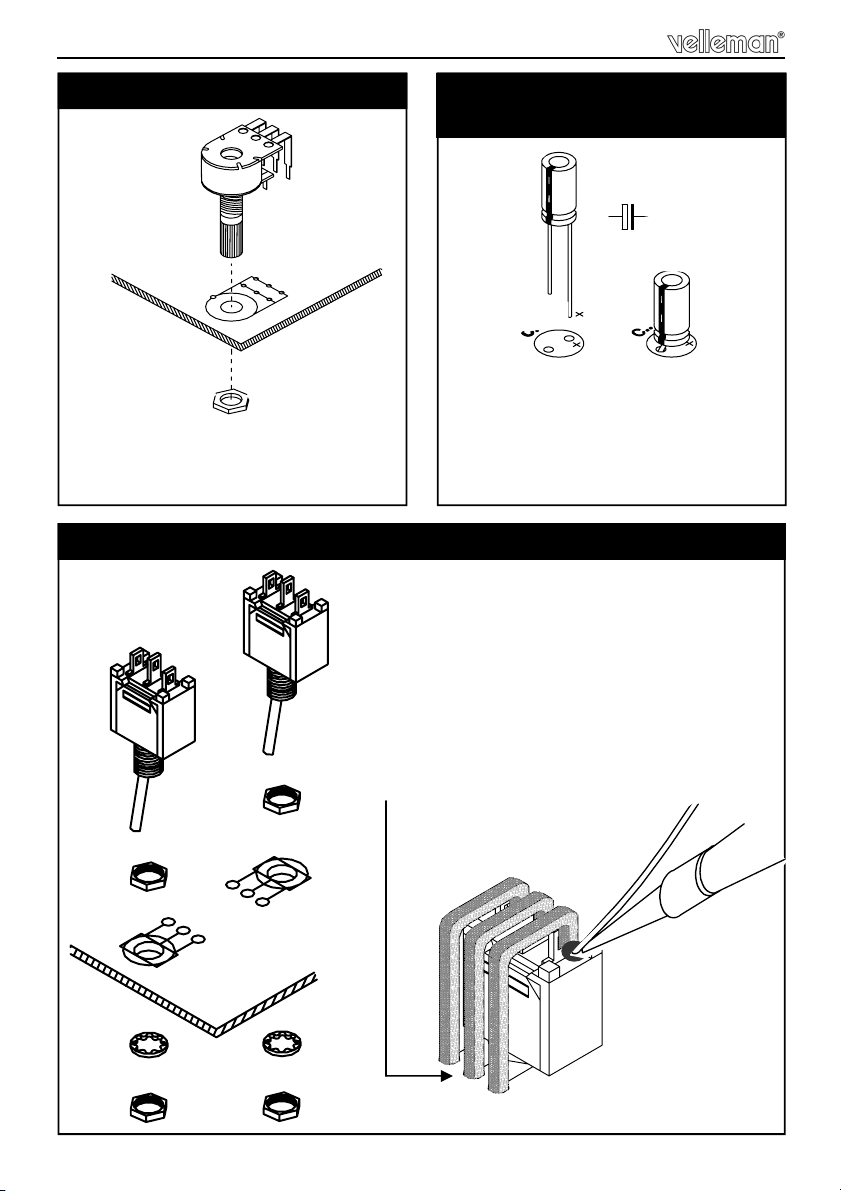

RV1 : Stereo log. 50K

RV2 : Stereo log. 50K

17. Potentiometers 18. Electrolytic capacitors.

Watch the polarity !

C...

SW1 : Phase

SW2 : Mode

Position the switches onto the PCB first.

Mount a wire jumper onto each switch

connector and connect these with the switch

connector on the PCB.

19. Switches

Fig 1.0

Fig 1.0

COMPONENT SIDE

COMPONENTSIDE

9

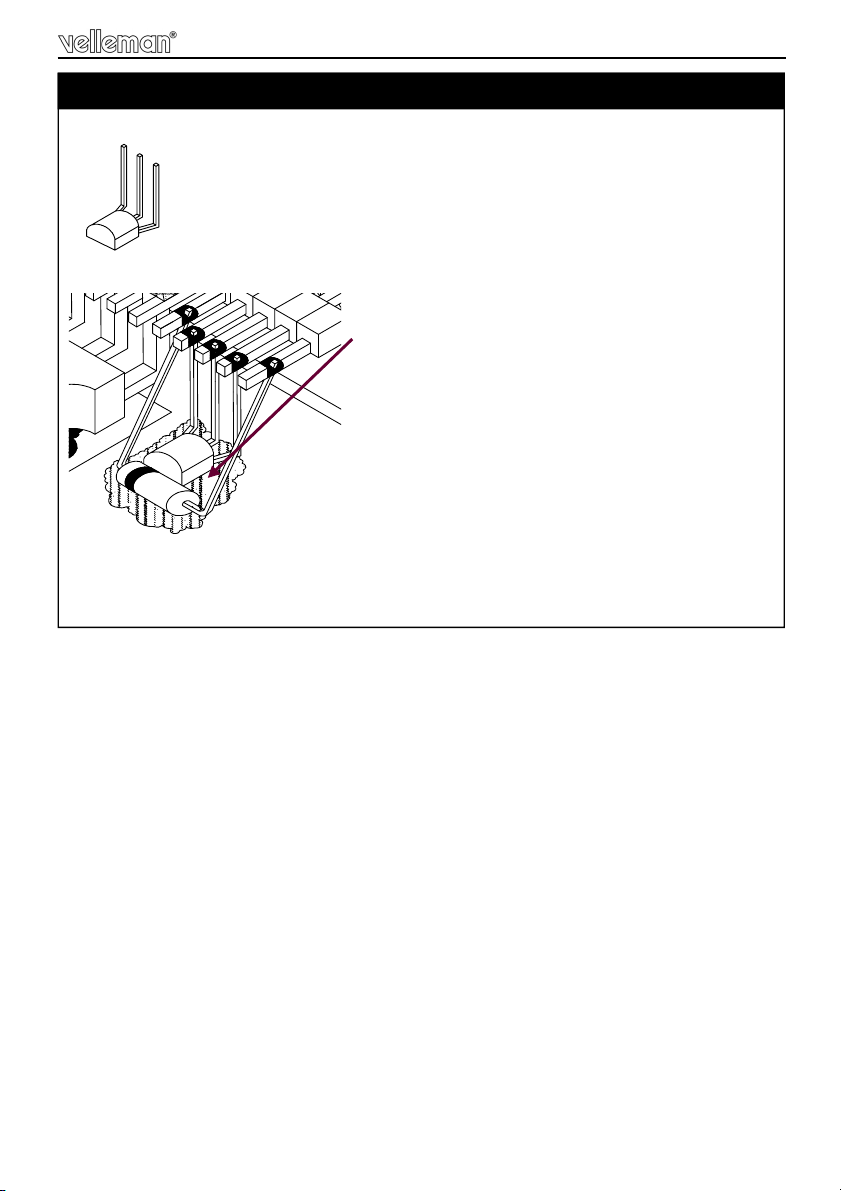

RY1 : VR5V242C

( 24VDC - 5A - 2C)

20. Relais

Construction

C37 : 3300µF / 50V

C38 : 3300µF / 50V

21. Electrolytic capacitors.

Watch the polarity !

C...

MOUNT THEM ON THE

SOLDERSIDE !

Mount first :

SK1 : LOW LEVEL IN 'RIGHT'

SK3 : HIGH LEVEL IN 'RIGHT'

Mount now :

SK2 : LOW LEVEL IN 'LEFT'

SK4 : HIGH LEVEL IN 'LEFT'

22. Female cinch connectors

SK...

SOLDERSIDE

SK...

LD1 : POWER (red)

LD2: ON (red)

Mount both LEDs on the solderside

at 8mm of the PCB cathode is

marked with 'C'.

23. LEDs

8mm

COMPONENT SIDE

SOLDERSIDE

Inspect the complete assembly.

Once the PCB is mounted on the

heatsink, the solderside is no

longer accessible.

Cathode Anode

10

Fixing the knobs

Slide the knobs fully onto the potentiometer axes.

Turn potentiometers fully counterclockwise

24. Fixing the knobs

!

Watch the position of

the dot !

11

25. Fixing the PCB onto the heatsink

M3 nut

Spacer

M3 bolt 16mm

Fixing the PCB

Fixing the PCB onto the heatsink :

(1) Slide 2 x 5mm plastic spacers over the black bolts.

(2) Carefully position the PCB onto the two bolts

(3) fasten using two nuts.

12

Tighten gently, making sure that :

• the leds protrude the holes

• the cinch (RCA) connectors do not touch the heatsink

• the knobs do not touch the heatsink

• the switches do not touch the heatsink

(4) fit the remaining bolts and spacers

(5) fit the nuts and tighten them all, while minding the position of the knobs,

switches, leds and connectors

5X

Fixing the PCB

13

26. Fixing the power transistors T8 (TIP147) & T9 (TIP142)

Fixing power transistors

bend both transistors as indicated.

• apply a drop of heat conductive compound on the heatsink.

• position the mica onto the heatsink so that the hole coincide with the hole in

the heatsink, press gently.

• apply a drop of heat conductive compound on the mica.

• Mount the transistor on the heatsink, using a 16mm bolt, lock washer and nut.

Make sure the transistor leads are correctly positioned

between the pins of the pinheader.

• Tighten gently.

+/-5mm

Heat conductive

compound

Lock washer

M3 nut

M3 bolt

mica

T8 (TIP147)

14

• Solder the transistor leads

Repeat for the remaining transistor T9 (TIP142)

Fixing Diode D15

Bend the leads as indicated.

Put a large drop of heat conductive

compound on the heatsink.

Solder the diode to the two outer pins of

the pin header.

Make sure that the diode is bend to-

wards the heat conductive com-

pound.

Mind the direction of the ring. It should

face transistor T9

27. Fitting diode D15 (1N4007)

!

15

Fitting transistor T7

Bend the leads as indicated.

Put a large drop of heat conductive compound

on the heatsink.

Solder the transistor to the remaining pins of

the pinheader.

The flat side of the transistor must face the

heatsink.

Make sure that the transistor and diode leads do not touch each other

and make sure that the diode does not touch the power transistor.

28. Fitting transistor T7 (BC547)

16

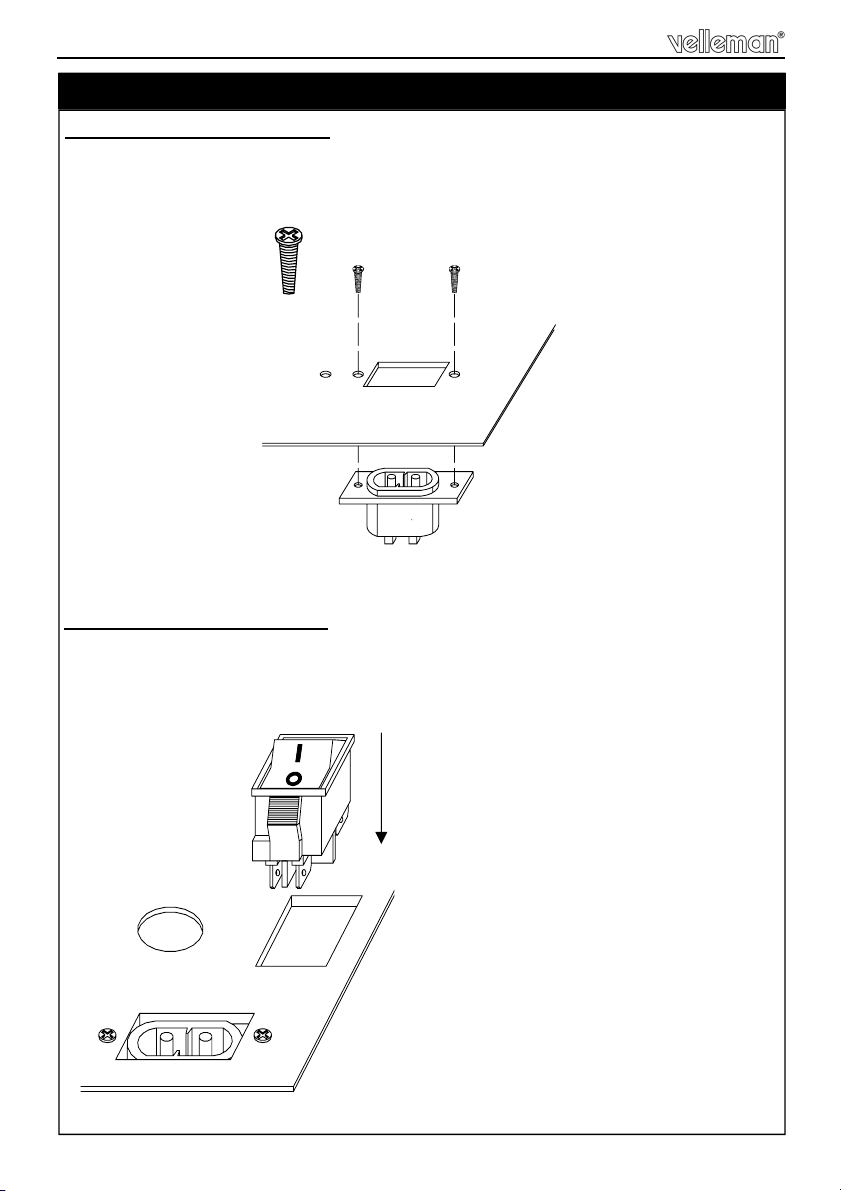

2. Mounting the power switch

Click the power switch onto the heatsink. Make sure the '0'-position of the switch

faces the AC connector.

Mounting power supply section

29. Mounting the power supply section

10mm screw

1. Mounting the AC connector

Position the AC connector at the PCB side of the heatsink and fix by means of

two 10mm black screws.

17

2A T

3. Mounting the fuse holder

Place the fuse holder and fix with the included nut.

Place a 2A T fuse.

Mounting power supply section

If necessary , enlarge mounting hole

18

4. Fixing the transformer

Rotate the transformer in such a way that the red/yellow/blue/grey wires point

towards the PCB.

Tighten the nut

Mounting power supply section

bolt

washer

transformer

washer

disk

nut

19

5. Wiring the ground connection

Connect one end of the cable to the red ring terminal.

Connect the ring terminal to the chassis

by means of a black bolt, spring washer

and nut.

Solder the other end to the PCB tab

(SK12)

Mounting power supply section

1 2

M3 nut

spring washer

16mm M3 bolt

Scratch off anodizing

for better conduction

20

6. Transformer wiring (red/yellow/blue/grey wires)

Slide an insulation sleeve over each wire.

Solder a connector to each wire

Slide the sleeve over the connector

• Connect the wires to the PCB. Mind the colours!

• Group the wires by means of two cable ties

• Cut the largest of the two heatshrink tubes into 3 pieces: 3cm - 3cm - 4cm

SOLDER

REMARK : In case you trim the wires, always

remove the insulating lacquer (+/- 1cm)

Mounting power supply section

GREY

RED

BLUE YELLOW

3cm 3cm 4cm

Other manuals for K8077

1

Table of contents

Other Velleman Subwoofer manuals

Popular Subwoofer manuals by other brands

Klipsch

Klipsch Reference Series RW-12d Specifications

JL Audio

JL Audio Stealthbox SB-S-LWAG/10W6v2/DG installation guide

Ground Zero

Ground Zero TITANIUM Series owner's manual

Ground Zero

Ground Zero RADIOACTIVE Series owner's manual

Axiom Audio

Axiom Audio EP125 owner's manual

L-Acoustics

L-Acoustics KIVA SB18i Rigging manual