User's manual Medium Comfort

8

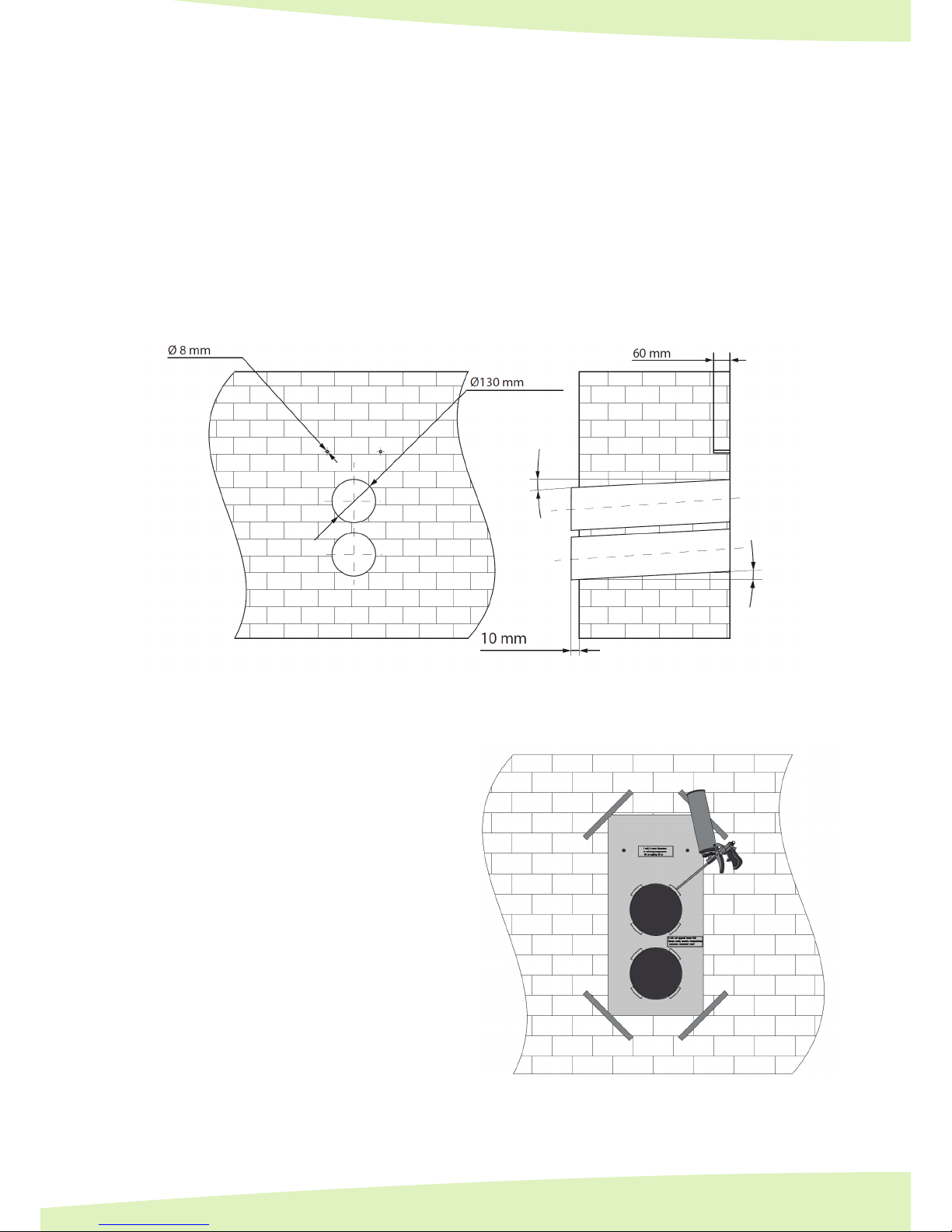

7. DESIGNS AND OPERATING LOGIC

• The unit casing is made of painted steel, internally lled

with a heat- and sound-insulating material.

• The plate heat exchanger and two fans are located inside

the unit.

• The front panel is installed on the rotating sleeves to

enable access for the unit servicing.

• The casing bottom is equipped with a protecting service

panel to enable service access to the automation unit.

• The supply lter is installed between the fan and the heat

exchanger and provides fresh ltered air supply to the

unit.

• The extract lter is installed in the upper part of the

front panel.

• The temperature sensor downstream of the heat

exchanger in the exhaust air duct provides the heat

exchanger freezing protection. If the exhaust air

temperature drops down below +3 ºC (+37,4 ºF) the

heat exchanger freezing danger is registered. In this case

the supply fan is turned off and the unit operates in

exhaust mode only. After the heat exchanger is warmed

up and the freezing danger is no longer imminent the unit

reverts to the standard operation mode.

Unit operation logic

Supply fan

Supply lter

Heat exchanger

Extract lter

Front panel

Control unit

Exhaust fan

Supply air

Extract air

Intake air

Exhaust air

Warm stale extract air from the room ows through the

air ducts to the unit, is puried in the extract lter, then it

is moved to the heat exchanger and exhausted outside by

the exhaust fan. Clean cold air from outside is moved by

supply fans to the unit where it is puried through the supply

lter.Then clean air ows through the heat exchanger and is

supplied to the room.

Heat energy contained in the warm extract air is transferred

to the fresh intake inside of the heat exchanger. Heat recovery

minimizes heat energy losses and operating heating costs.