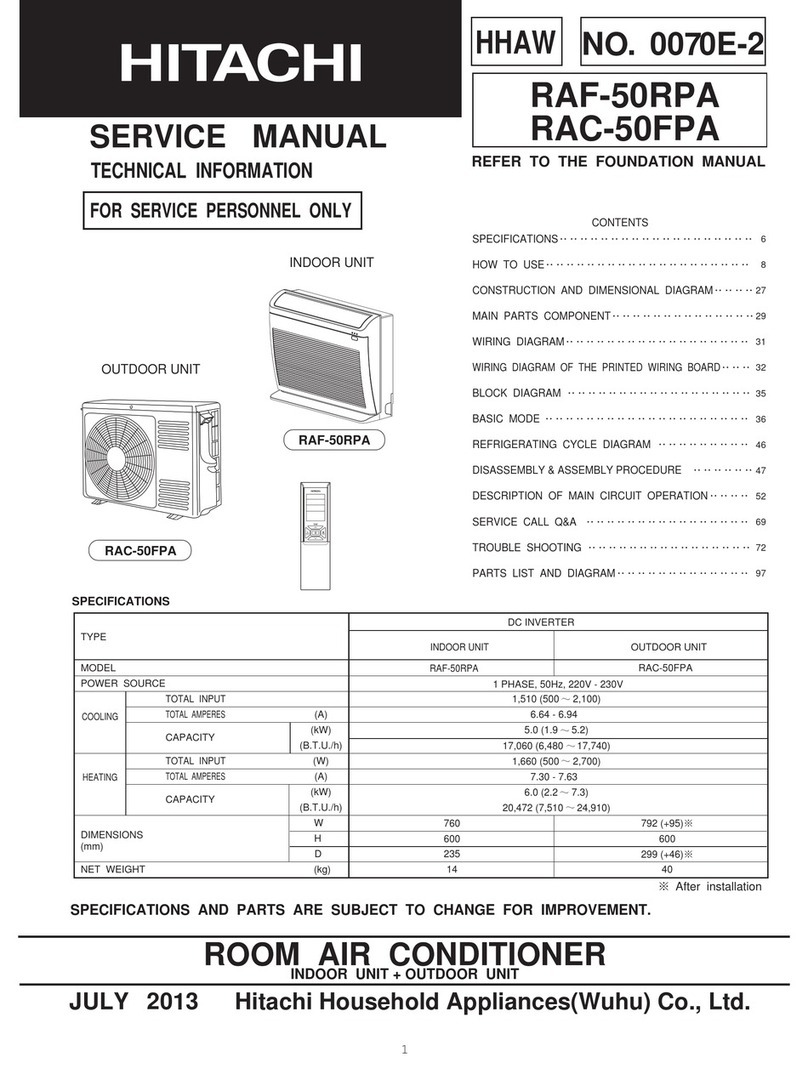

Contents

Contents......................................................................................................................................... 2

Figure table .................................................................................................................................... 2

Before starting................................................................................................................................ 4

Electrical connection....................................................................................................................... 5

Installing Compact P....................................................................................................................... 6

Condensation drain/water trap........................................................................................................ 9

Water connection.......................................................................................................................... 10

Duct connection............................................................................................................................ 12

Supplementary heating element DHW.......................................................................................... 13

Start-up and configuration of CTS602 controls............................................................................. 14

Startup...................................................................................................................................... 14

CTS602 configuration ............................................................................................................... 14

Activating the SERVICE menu.................................................................................................. 15

Inlet heating.............................................................................................................................. 16

Hotwater ................................................................................................................................... 17

Air quality.................................................................................................................................. 18

Air exchange............................................................................................................................. 19

Defrost...................................................................................................................................... 20

Temp. control............................................................................................................................ 21

Inlet control............................................................................................................................... 22

Room control ............................................................................................................................ 23

Restart...................................................................................................................................... 24

Preset....................................................................................................................................... 25

Manual...................................................................................................................................... 26

Fault finding.................................................................................................................................. 27

Maintenance................................................................................................................................. 28

Energy saving............................................................................................................................... 30

Accessories / spare parts ............................................................................................................. 31

Figure table

Figur 1: CTS 602 Control Panel...................................................................................................... 5

Figur 2: Duct Connections.............................................................................................................. 6

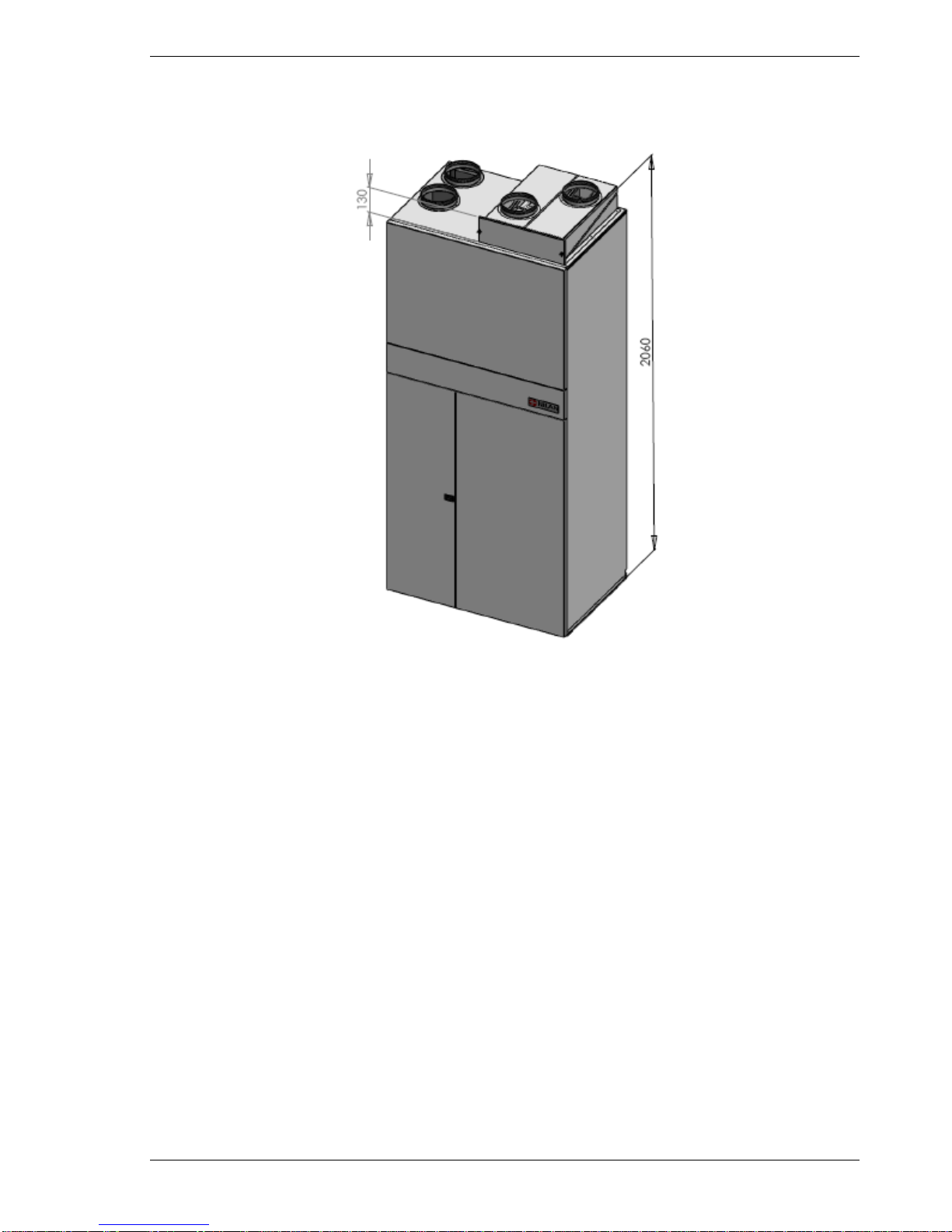

Figur 3: Sketch of Compact P......................................................................................................... 7

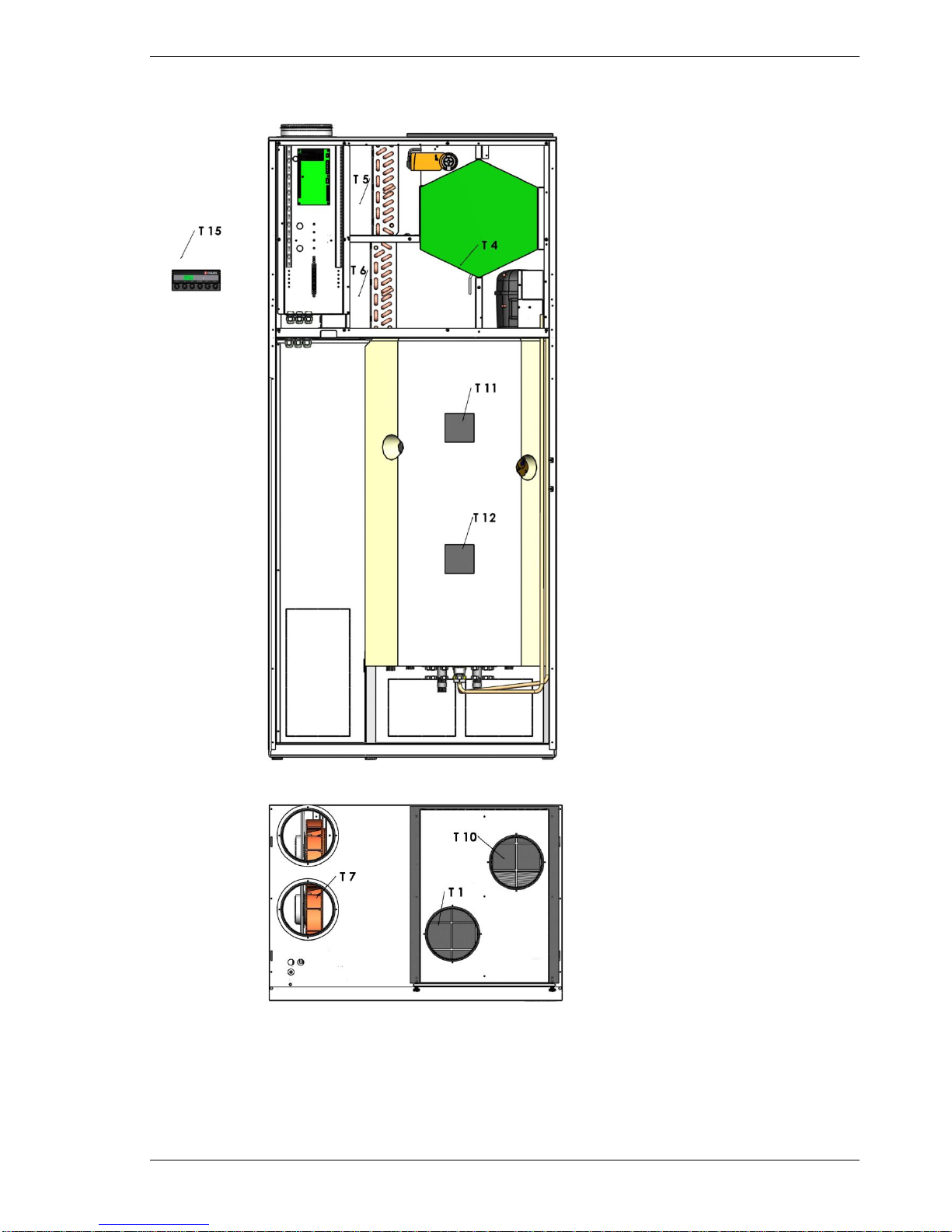

Figur 4: Location of temperature sensors ....................................................................................... 8

Figur 5: Location of sacrificial anode............................................................................................. 10

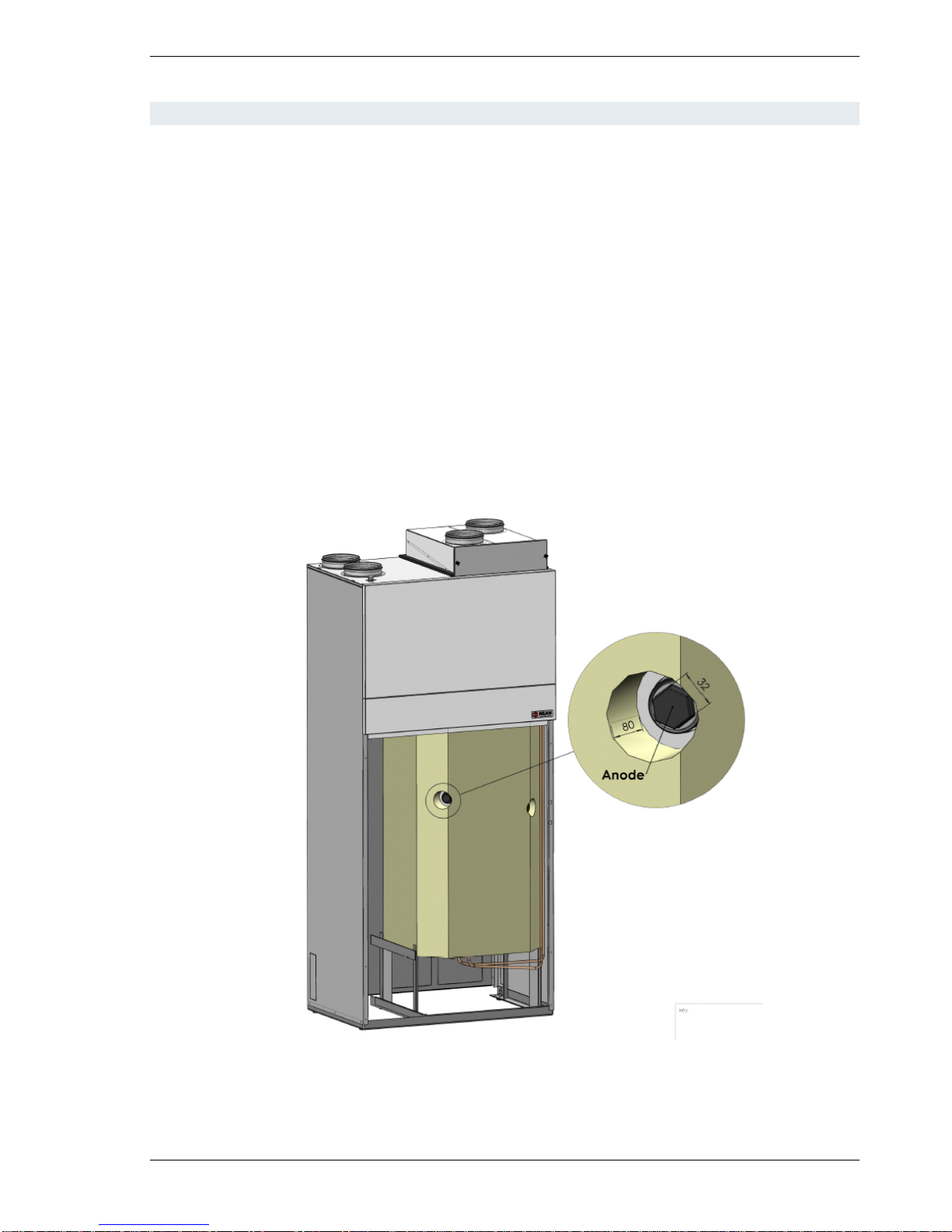

Figur 6: Water connections............................................................................................................11

Figur 7: Insulation of ducting......................................................................................................... 12

Figur 8: Headlines in the service menu......................................................................................... 15

Figur 9: The "inlet heating" Menu.................................................................................................. 16

Figur 10: The "Hotwater" Menu..................................................................................................... 17

Figur 11: The "Air quality" Menu.................................................................................................... 18

Figur 12: The "Air exchange" Menu.............................................................................................. 19

Figur 13: The "Defrost" Menu ....................................................................................................... 20

Figur 14: The "Temp. control" Menu.............................................................................................. 21

Figur 15: The "Inlet control" Menu................................................................................................. 22

Figur 16: The "Room control" Menu.............................................................................................. 23

Figur 17: The "Restart" Menu ....................................................................................................... 24

Figur 18: The "Preset" Menu......................................................................................................... 25

Figur 19: The "Manual" Menu ....................................................................................................... 26

Figur 20:Air Filter change............................................................................................................. 28

Figur 21: Safety Switch................................................................................................................. 29