9

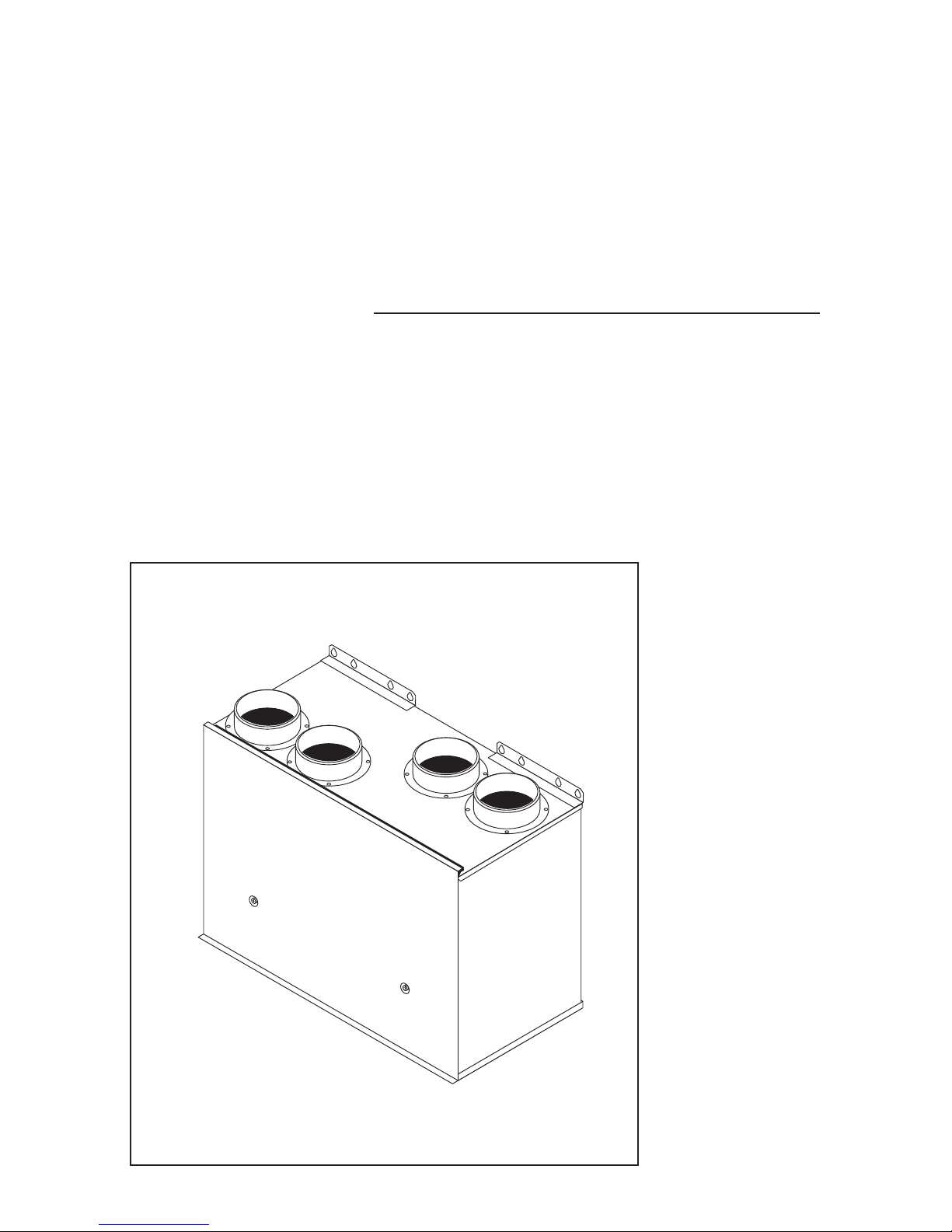

6.0 Installation Requirements

6.1 Location and Site Requirements

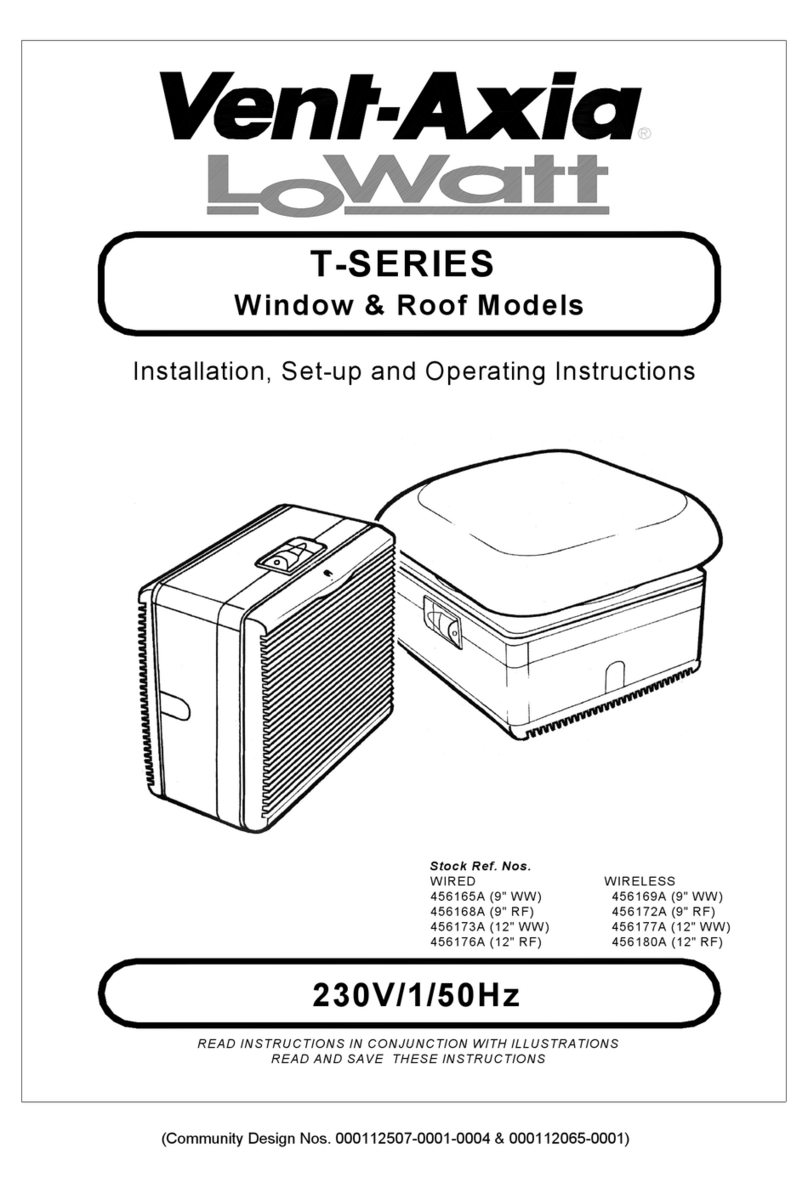

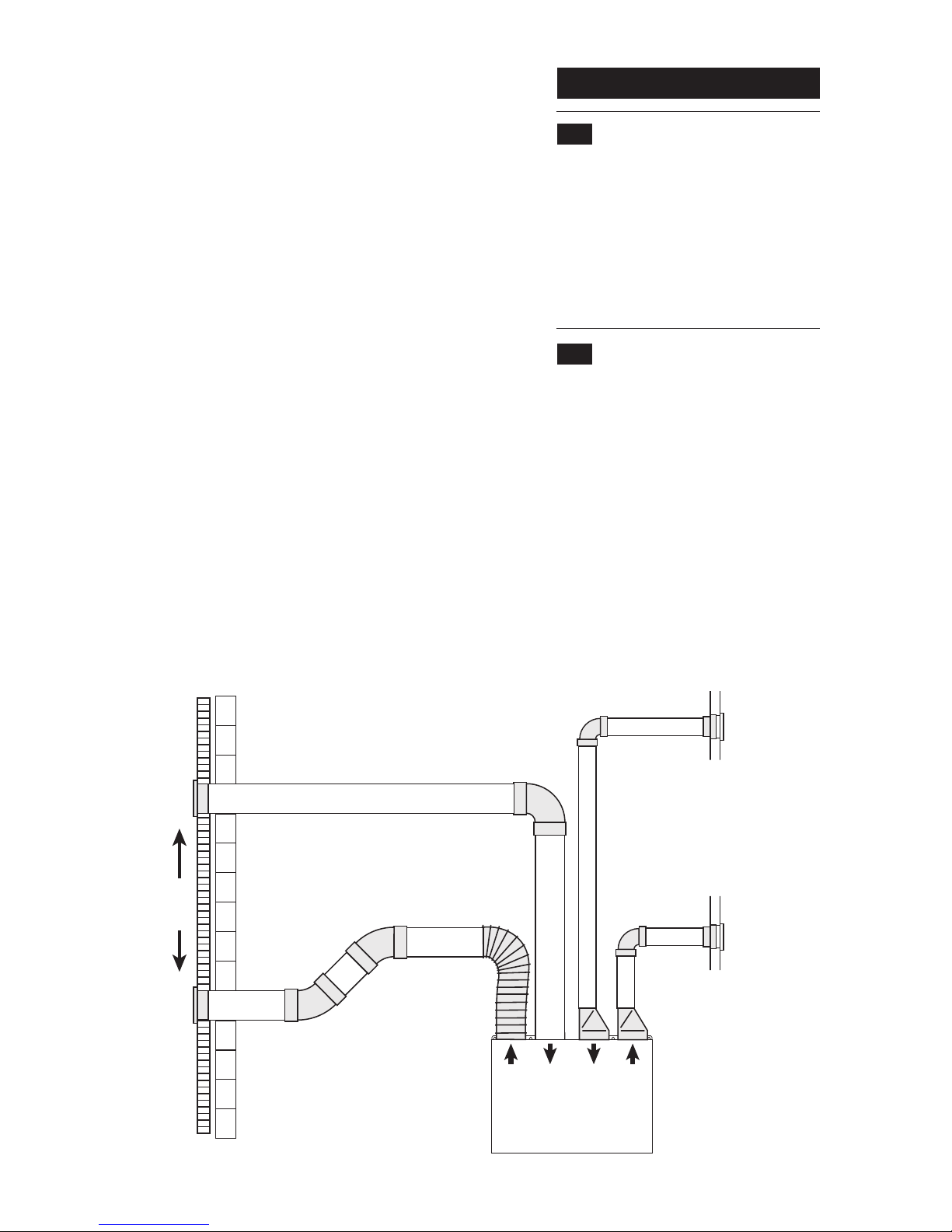

All dimensions

in mm

Total required

(including clearances)

Height - 692

Width - 562

Depth - 530

Minimum top

clearance

for servicing

200

Minimum

side

clearance

5

Minimum

side

clearance

5

Minimum bottom

clearance

100

Minimum front

clearance

for servicing

250

Fig. 7

Clearances

1. Read the instructions fully before installing or

using the appliance.

2. The installation must be carried out in

accordance with the manufacturer's instructions

by a competent person and comply with the

relevant Building Regulations and the current

I.E.E Wiring Regulations.

3. Duct systems should be installed in

accordance with BRE Digest 398 and CIBSE

guides.

4. Consideration must be given to the position

of the ductwork connections, the electrical

connection and the condensate pipe

connection.

5. The exhaust duct must pass through an

outside wall or roof and discharge to

atmosphere in a suitable position. The clean air

inlet duct must pass through an outside wall or

roof and be suitably positioned to provide an

adequate fresh air supply from atmosphere.

6. The ventilation for any open flued appliance

must always be considered before siting the

extract and inlet vents. The vents must also be

sited away from other flue terminals, ventilators

etc. on the outside of the dwelling. In addition,

there shall be adequate ventilation of the kitchen

when a cooker hood is used at the same time as

appliances burning gas or other fuel. The

exhaust air duct must not be discharged into a

flue which is used for exhausting fumes from

appliances burning gas or other fuels. Refer to

the relevant current British Standard Codes of

Practice, Part J of the Building Regulations

(England and Wales) and, in Scotland, OFTEC

Technical Information Sheet TI/112.

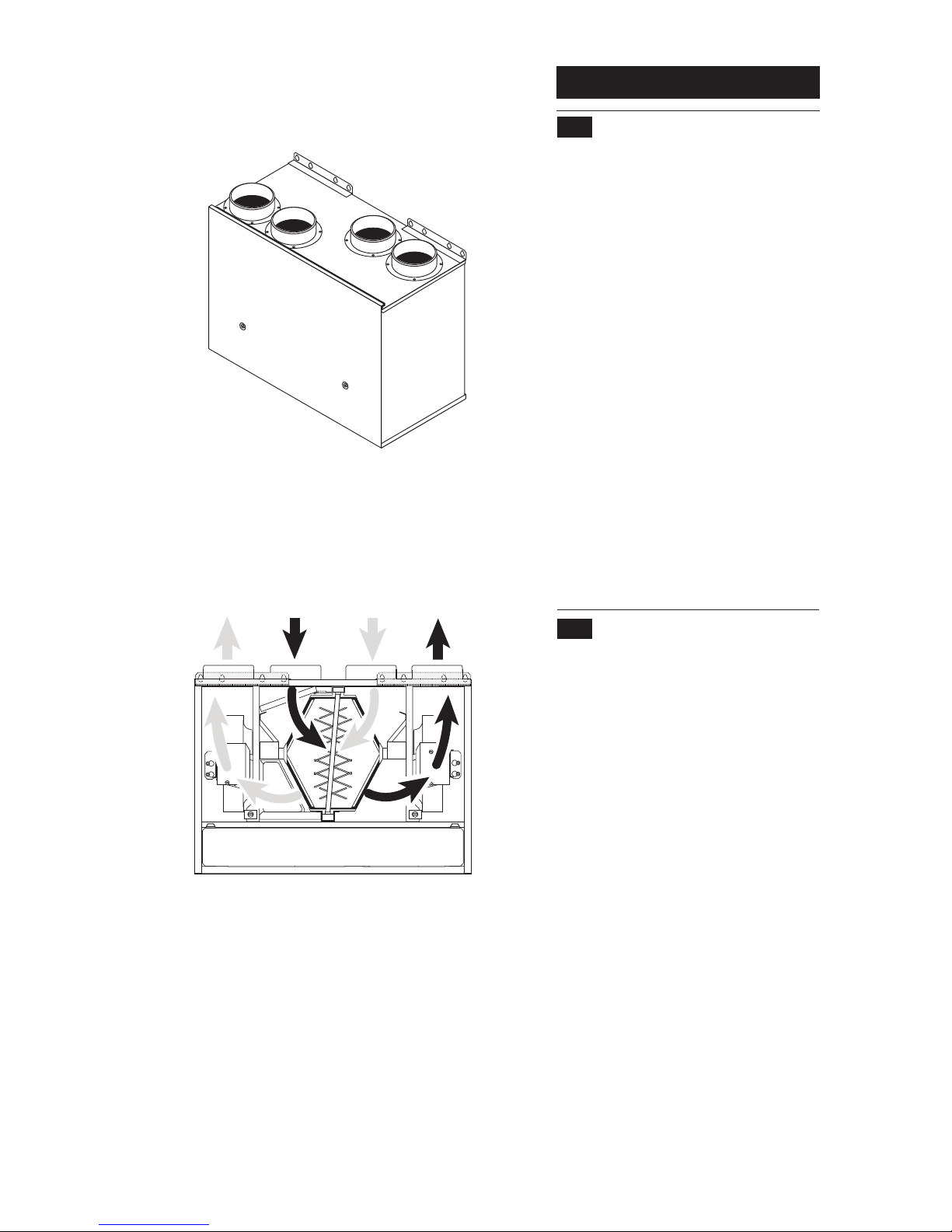

7. The LoWatt HR204 is not suitable for

installation above any cooking appliance or with

any extraction system servicing a cooking

appliance.

8. If the unit is fitted in a room containing a bath

or shower then reference should be made to the

current I.E.E Wiring Regulations.

9. A flat vertical area 692mm high x 562mm wide

is required for installation.

10. It is important that any door or cupboard

front covering the LoWatt HR204 is easily

removable by the user as access for regular

cleaning is required.

11. Check that the information on the rating

label is compatible with the supply. See Fig 2.

12. The addition of anything that may interfere

with the normal operation of the appliance could

invalidate the appliance warranty and infringe

regulations.

Note: Clearances do not take into

account any acoustic mat that may

be fitted between the unit and the

wall.