“K-SERIES” INSTALLATION DO'S & DON'TS

(also see the separate specification procedures and installation instructions)

Range hoods and liners must be properly designed and installed in order for them to be

effective. No manufacturers exhaust system will work properly if it is poorly designed and/or

improperly installed. If a Vent-A-Hood does not seem to be working properly, there could be a

mechanical problem with the hood, but that is far-and-away the least likely cause. Vent-A-Hood,

properly specified and installed, works - period! The problem is virtually always a violation of one or

more of the 11 items detailed below.

Poor design and/or improper installation are the first places to look if the ventilator is not removing the

cooking pollutants.

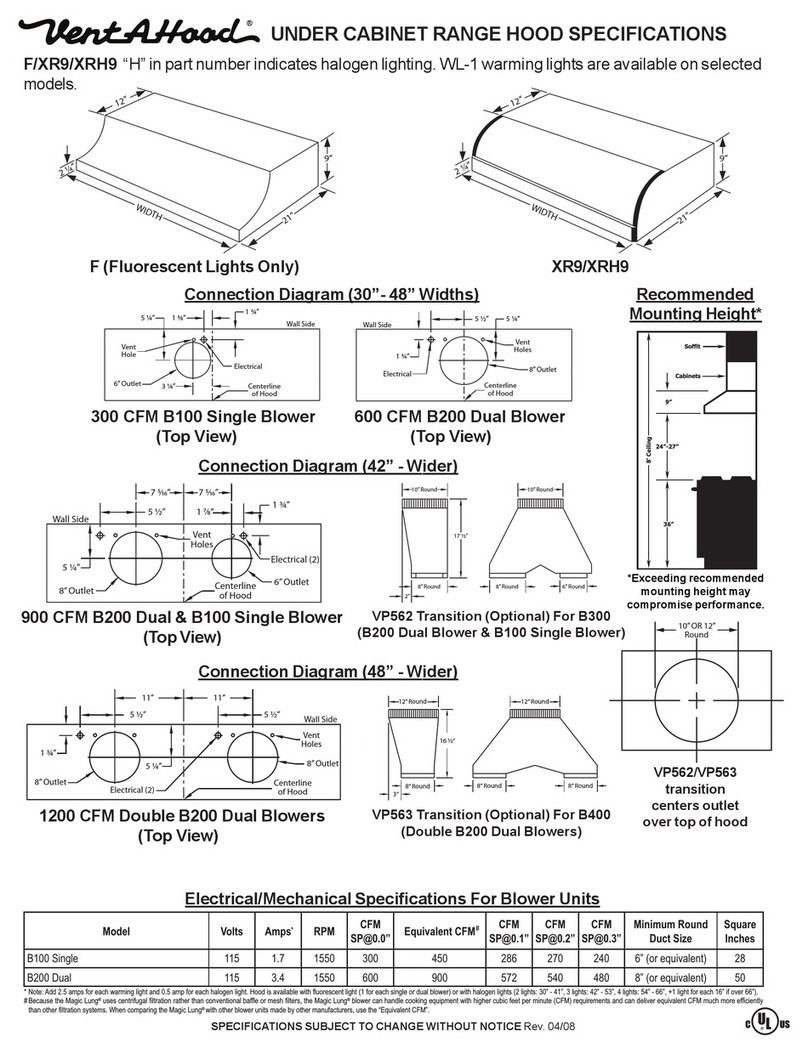

1). Use properly sized, smooth galvanized ductwork, making the duct run as short and

straight as possible.

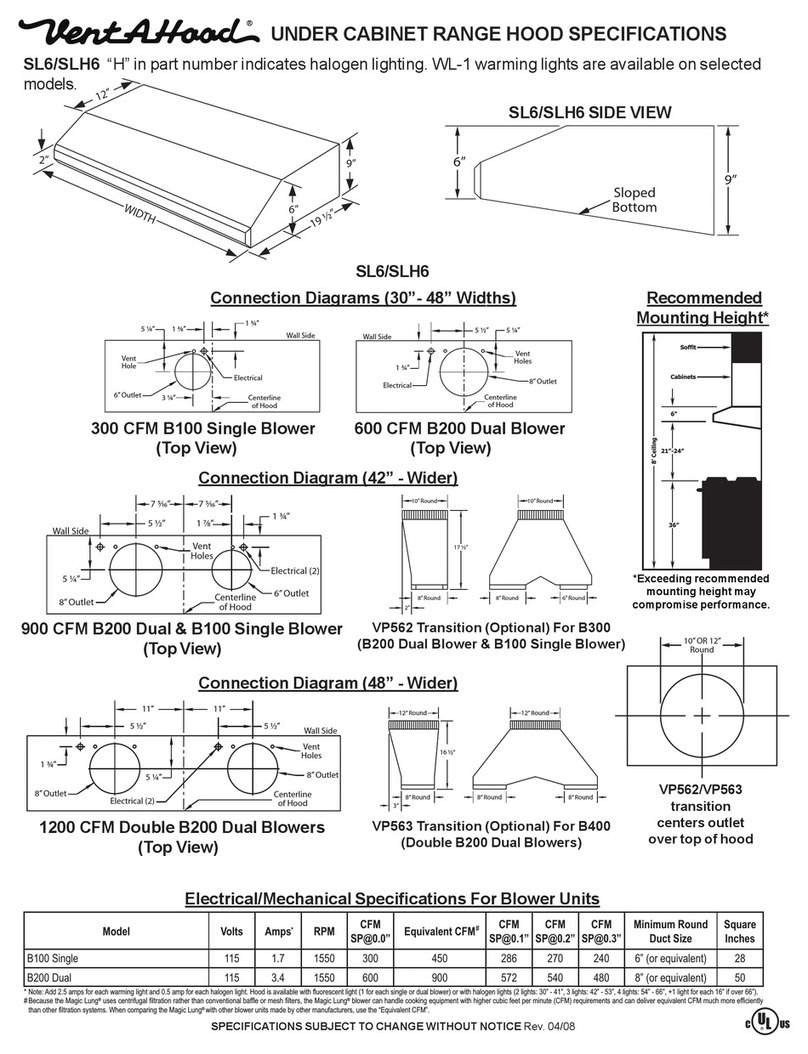

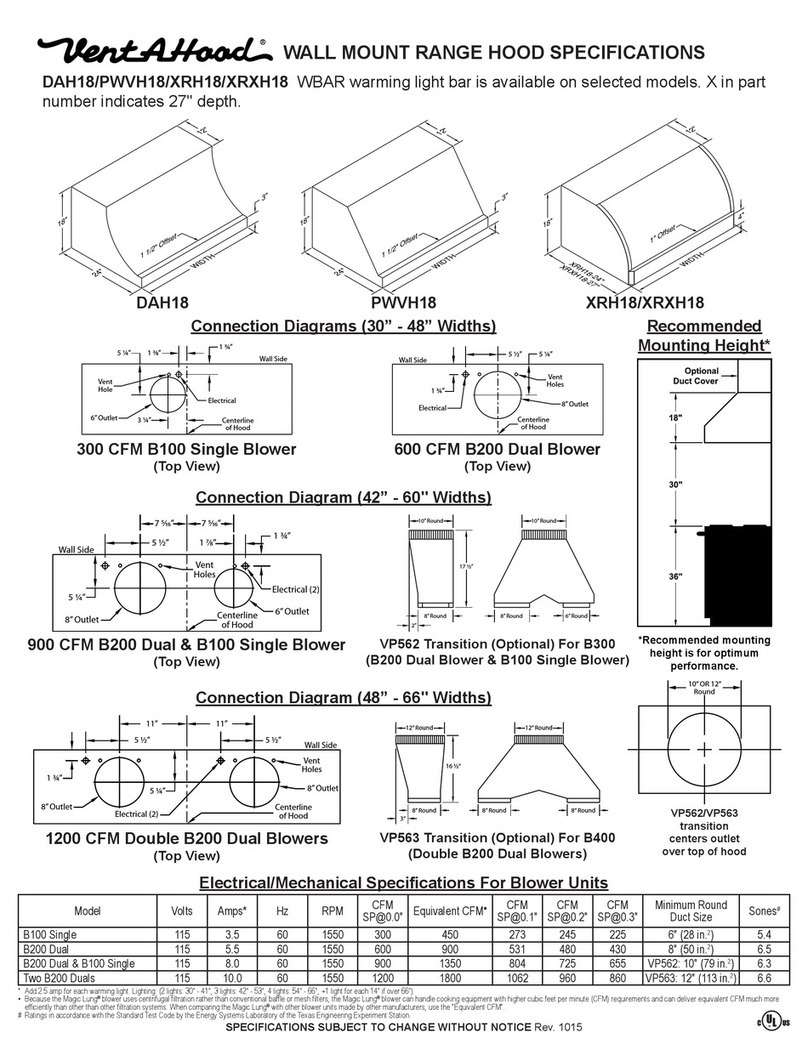

Blower Correct Duct Size Round Equivalent

240cfm 3-1/4” x 10” 7"

(32.5 sq. in.) (38.5 sq. in.)

2). DO NOT reduce the suggested minimum duct size, (as outlined above), ANYWHERE in

the duct run. Even at the wall cap or roof jack. A 5" duct in place of a 6" duct will reduce

a 300cfm air flow to 205cfm and a 7" duct in place of an 8" duct will reduce a 600cfm air

flow to 400cfm.

3). DO NOT USE flexible ductwork. The ribbing creates resistance to air flow and reduces

exhaust efficiency tremendously.

4). DO NOT TURN SHARP CORNERS. Make gradual turns in the duct run.

Rapidly moving air cannot make sharp 90°turns.

5). IF AT ALL POSSIBLE - do not space 90°elbows closer than 6 feet to each other.

6). TAPE ALL JOINTS with duct tape in order to prevent leakage of any pollutants into the wall, joist,

basement or attic spaces.

7). DO NOT USE SCREWS to attach ductwork to the duct collar on the top/back of the hood. Protruding

screws may keep the backdraft damper from opening and closing properly.

Make sure all backdraft dampers open and close completely and freely!

8). INSULATE THE DUCTWORK in cold spaces to prevent moisture condensation in the winter, which can

run down the ductwork into the cabinet below.

9). NO SCREENING MATERIAL on the wall caps or roof jacks. Screens cut air flow by 20-50% and should

not be used.

10). THE AIR SHOULD NOT "DEAD END" into the top of wall caps or roof jacks. Openings on wall caps or

roof jacks should be wide enough and deep enough to allow the air to flow continuously and freely. Wall

caps and roof jacks should have solid, gravity dampers that will open and close freely with the air flow.

Vent-A-Hood dealers have access to all the appropriate wall caps and roof jacks.

11). Due to tighter construction techniques being used in homes today, it is important to replace any air

removed from the home via a safe pathway from the outside. If this is not done, the possibility exists that

fireplaces, furnace flues etc. may be backdrafted. If it is starved of air to exhaust due to inadequate

make-up air, a range hood or liner may perform poorly, evidenced by cooking contaminants not being

completely exhausted to the outside.To avoid these potential problems, consult an HVAC professional

who is qualified to determine if, and how much, make-up air is needed.

Thank you for choosing !

Distributed By: Shady Oak Distributing, 616 - 13th Avenue South, Hopkins, MN 55343

Ph: (952) 935-3305 Toll Free: (888) 933-6529 Fax: (952) 224-3610