TABLE OF CONTENTS

3

INTRODUCTION PAGE 5

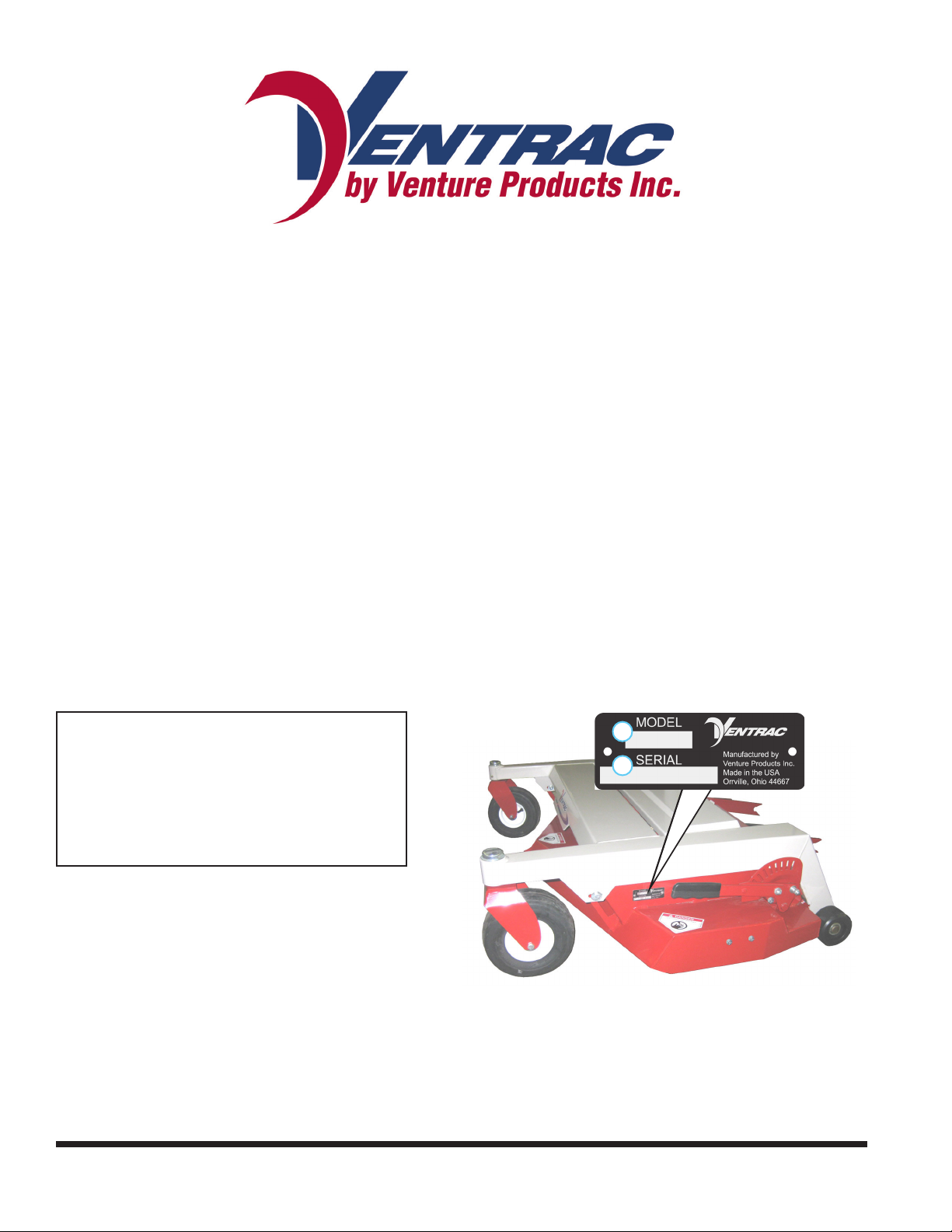

Product Description................................................................................................................................5

Why Do I Need an Operator’s Manual? .................................................................................................5

Using Your Manual.................................................................................................................................6

Manual Glossary ....................................................................................................................................6

SAFETY PAGE 7

Safety Decals .........................................................................................................................................7

Training Required...................................................................................................................................9

Personal Protective Equipment Requirements ......................................................................................9

Operation Safety ....................................................................................................................................9

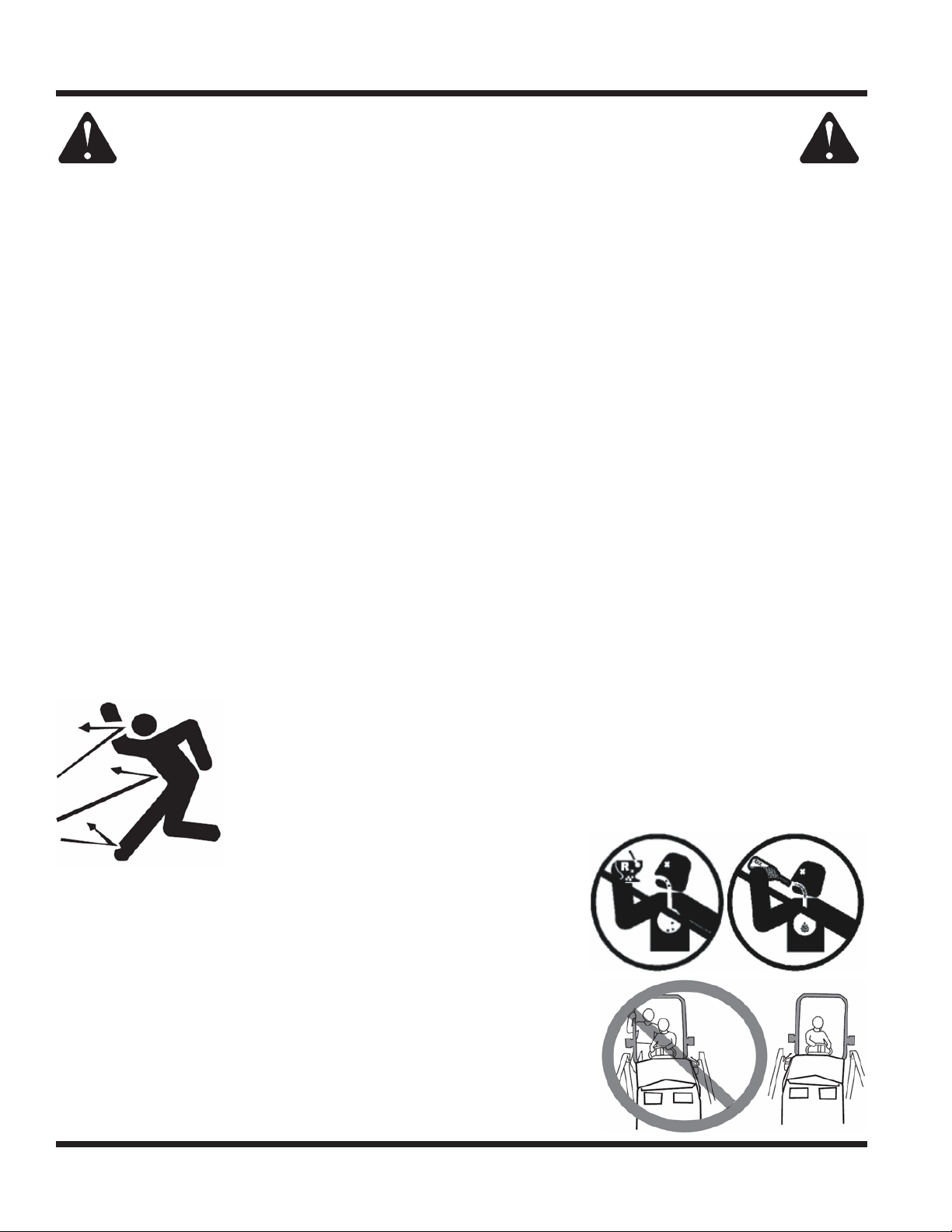

Preventing Accidents............................................................................................................................10

Keep Riders Off....................................................................................................................................10

Operating On Slopes............................................................................................................................ 11

Roadway Safety................................................................................................................................... 11

Truck Or Trailer Transport .................................................................................................................... 11

Maintenance.........................................................................................................................................12

Fuel Safety...........................................................................................................................................12

Hydraulic Safety ...................................................................................................................................13

Cutting Unit Safety ...............................................................................................................................14

OPERATIONAL CONTROLS PAGE 15

Operational Control Locations..............................................................................................................15

Main Belt Tensioner (A)........................................................................................................................15

Height Adjustment Handle (B)..............................................................................................................15

GENERAL OPERATION PAGE 16

Daily Inspection....................................................................................................................................16

Attaching ..............................................................................................................................................16

Detaching.............................................................................................................................................16

Mowing and Operating Procedure .......................................................................................................16

Transport of Mower ..............................................................................................................................17

Cutting Height Adjustment....................................................................................................................17

SERVICE PAGE 18

Cleaning and General Maintenance.....................................................................................................18

Deck Flip-Up Procedure (Service Position)..........................................................................................18

Mower Blade Removal & Installation ...................................................................................................18

Sharpening Blades...............................................................................................................................18

Belt Inspection......................................................................................................................................18

Deck Belt Replacement........................................................................................................................19

Tire Pressure........................................................................................................................................19

Deck Leveling Procedure.....................................................................................................................19

Lubrication Locations ...........................................................................................................................20

Storage.................................................................................................................................................20

Maintenance Schedule.........................................................................................................................21

Maintenance Checklist.........................................................................................................................21