LX420 Safety Procedures

Never operate snow blower when people are in the area. Frozen snow, ice, gravel, and other objects

can be thrown at lethal velocity.

Operators should be familiar with the area they are clearing and make preparations ahead of time.

Place guide stakes appropriately and remove stones, markers, or other debris that may be hidden

after a snowfall. Curbs, offsets, steps, man hole covers, broken or raised pavement, etc. should be

noted. Operators should map areas to be cleared before the winter season so they can review

potential hazards prior to clearing snow in the area.

If an area is to be cleared that is unfamiliar to the operator, travel slowly and use EXTREME

CAUTION. Inquire of anyone who might know of potential hazards.

The operator should never proceed if visibility is poor. If the tractor is equipped with a cab, the

windshield must be kept clean.

Discharge snow with the wind direction as much as possible. Discharging into the wind reduces

blowing distance and visibility.

Use caution when operating around objects that can obstruct your vision.

Shut off the PTO when you are not blowing snow.

Always shut off the PTO and engage the parking brake before dismounting to change the angle of the

discharge chute deflector.

Never travel at speeds that would cause injury to the operator or damage to the machine, if the

machine were to be stopped suddenly by an unseen, immovable object.

SAFETY

B-4

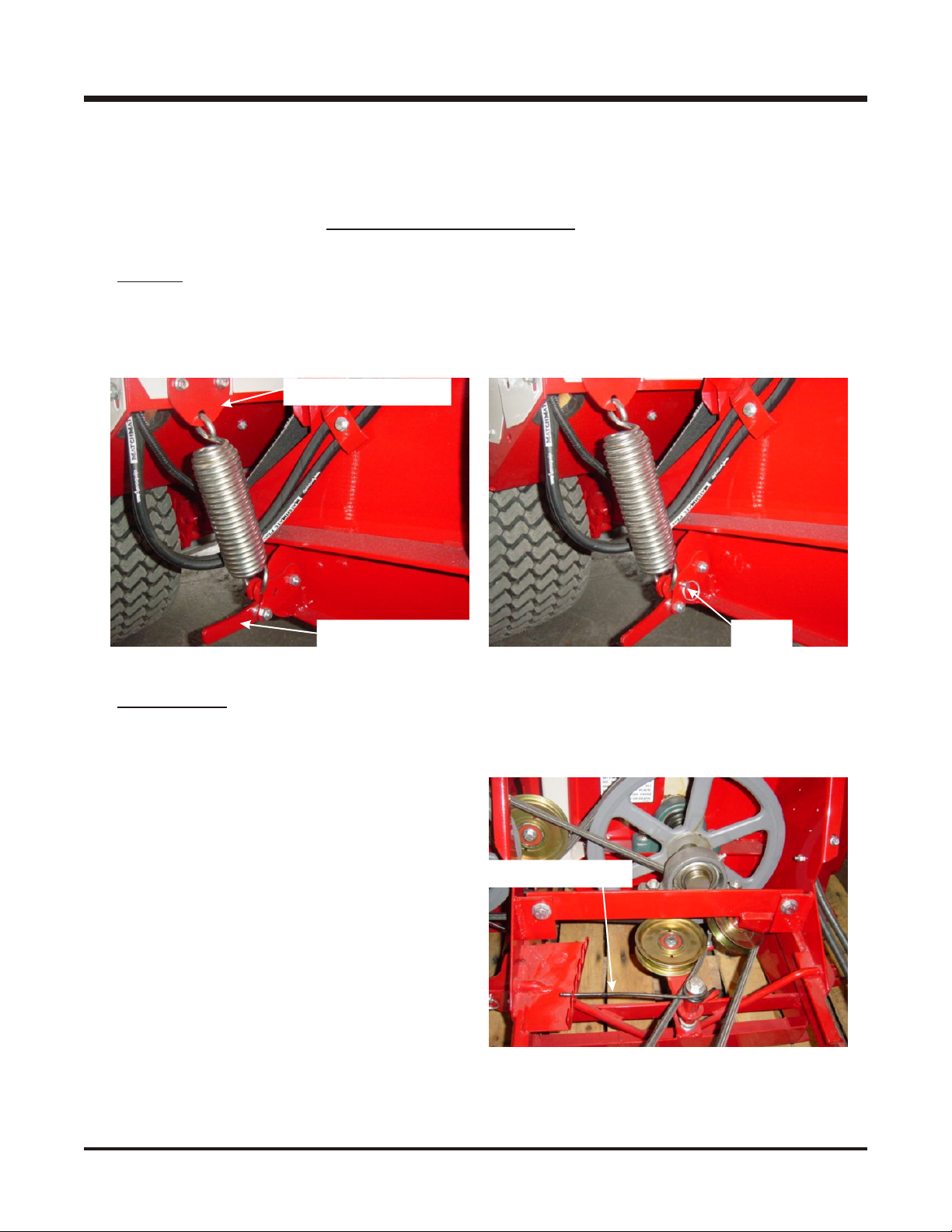

Before making any repairs or adjustments, engage

the parking brake, lower attachment to the ground,

shut the engine off, and remove the key.

Read and understand the operator’s manual

before operating this equipment.

Never direct the snow blower discharge chute to-

ward people, animals, buildings, vehicles, or other

personal property. Debris can be thrown from the

chute causing damage, serious injury, or death.

Before operating any LX420 prior to serial

AB1135 with a LE3100 or LE3200 that is

equipped with a tractor cab, a new center post

(Kit #70.3022) must be installed, or the tractor

cab must be removed. Damage may occur to

the cab if proper precaution is not followed.

See Warning Above

Before Operating the

LX420 with a LE Cab!