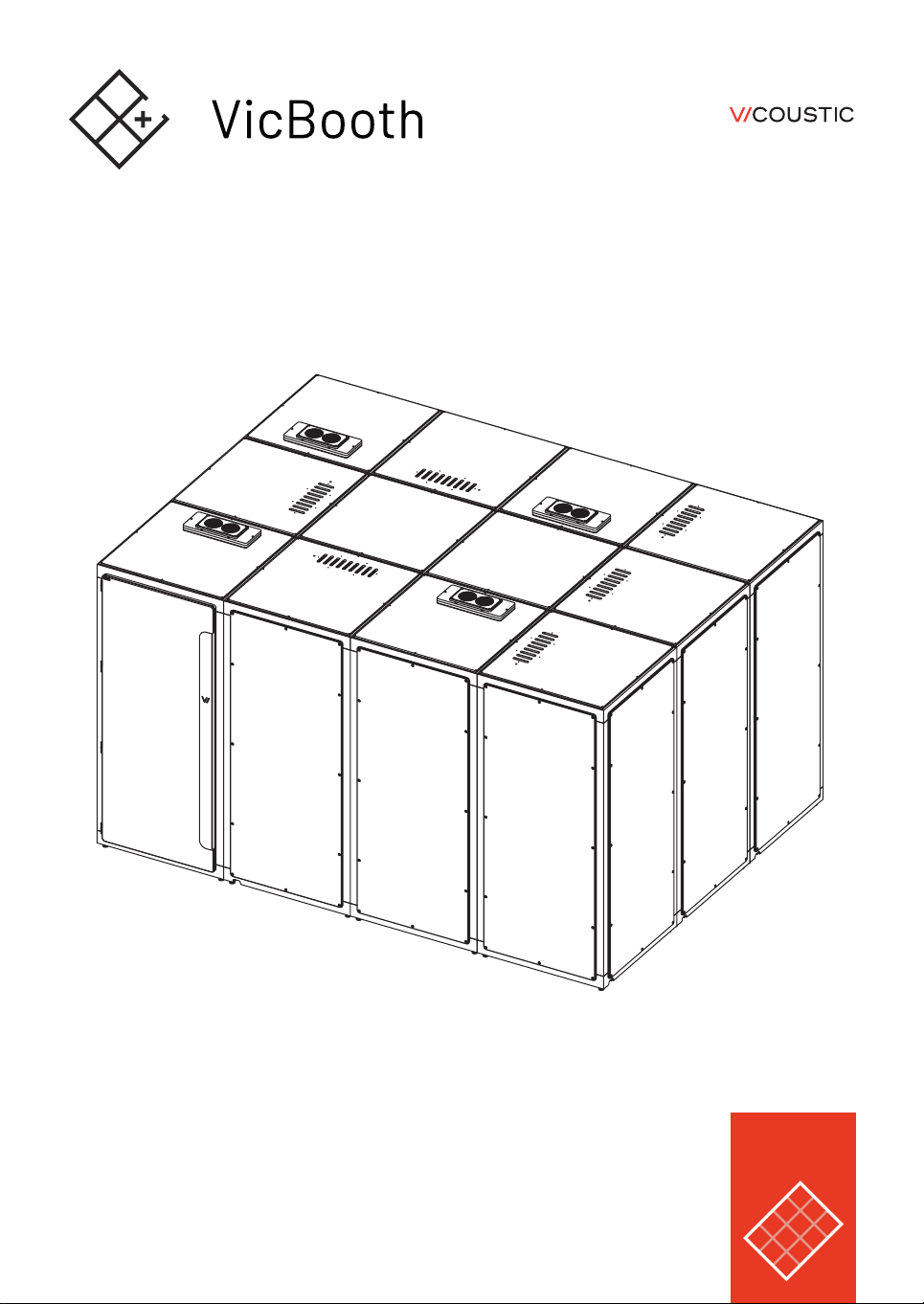

Vicoustic VicBooth Spa User manual

Popular Hot Tub manuals by other brands

CalderaSpas

CalderaSpas CalderaSpas Utopia Series owner's manual

anko

anko SS-601A user manual

CalderaSpas

CalderaSpas CANTABRIA owner's manual

Dimension One Spas

Dimension One Spas HYDRO SPORT Installation and owner's guide

Bestway

Bestway Lay-Z-Spa Maldives HydroJet Pro manual

Dimension One Spas

Dimension One Spas Nautilus Specifications