3 | 6

Thank you for purchasing “виктор” (VICTOR) power tools

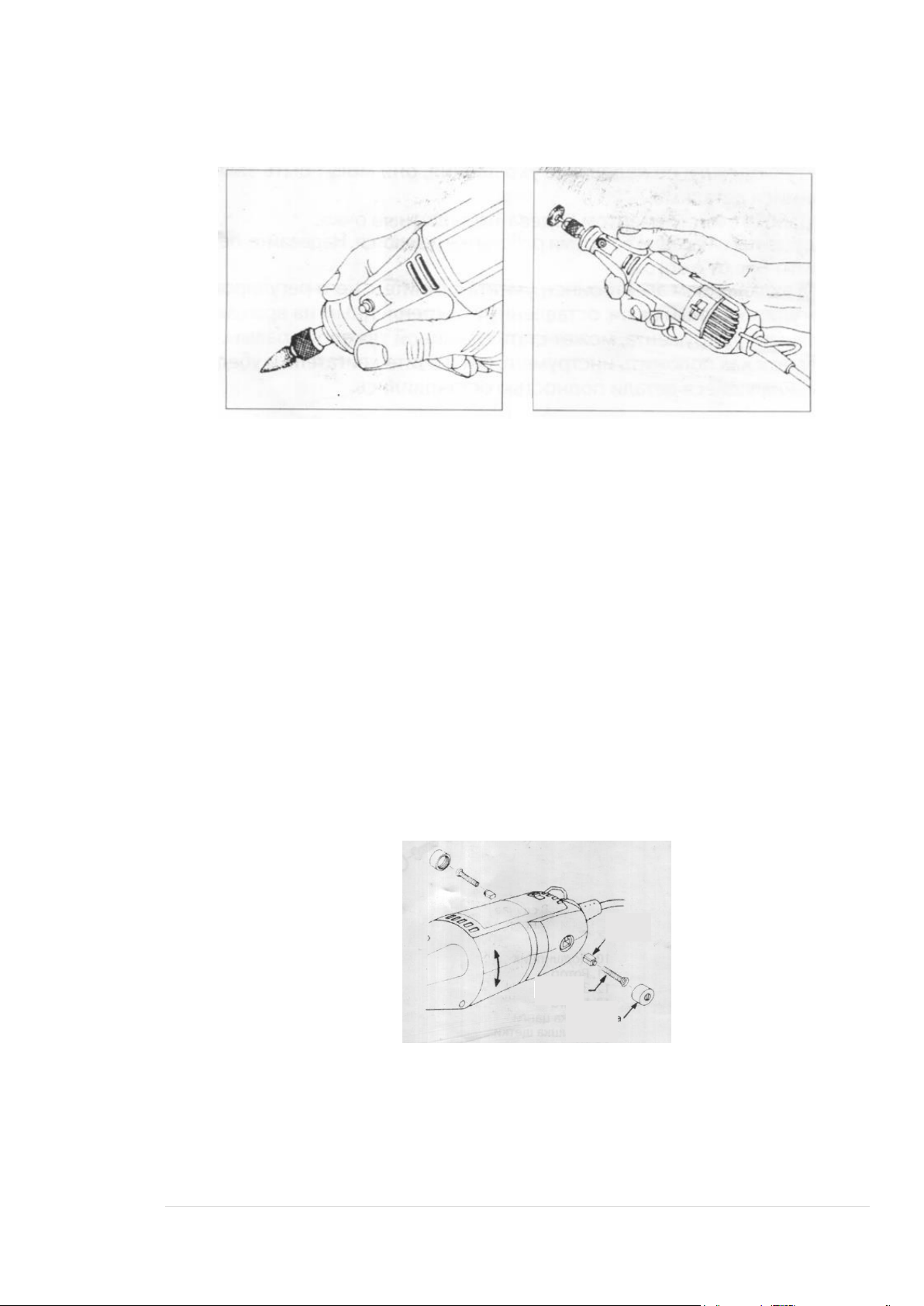

This power tool, here in after referred to as a tool, is designed to process various small

surfaces with interchangeable nozzles. The tool has a five-speed switch.

Technical specifications

Model : виктор MG-320

Supply voltage: 230 V

Output power: 320 W

Number of revolutions/RPM : 8000 - 33000

Max. drilling diameter: 1.0 - 3.2 mm

ATTENTION! Before starting work, carefully read the instructions.

Safety recommendations

1. The work area must be well lit and kept clean.

2. Do not use the tool in the presence of dust, flammable liquids, gases. During

operation, sparking of the tool is possible, which can lead to ignition.

3. Keep children or unauthorized persons away while working with the tool.

4. The plug of the drill’s cable must comply with the standard of the power outlet.

In no case do not modify the design of the tool, plug and power cable.

5. During operation, avoid contact of body parts with grounded objects: pipelines,

heating radiators, electric stoves and refrigerators.

6. Do not expose the instrument to liquids.

7. In no case do not carry the tool while holding the cable, do not pull on the cable

when disconnecting from the power outlet. Do not expose the cable to solvents

or oils. Avoid contact with sharp nozzle edges and moving parts.

8. When using the tool, use a power source equipped with a residual current

device (RCD). Use of an RCD reduces the risk of electric shock.

9. Before connecting the instrument to a power outlet, check the position of the

switch; it must be in the “off” position.

10. When working with the tool, do not wear loose or unfastened clothing, don’t

wear jewellery; they can be caught in moving parts.

11. Wear safety goggles when working with the tool.

12. Tools and tips heat up during operation. Wear gloves to protect against burns.