The Handy THMT26 User manual

24/11/2017

26cc PETROL

4 in 1 MULTI-TOOL

Model No: THMT26 -- Product No: 1938176001

ASSEMBLY REQUIRED

SAVE THESE INSTRUCTIONS

SPARES & SUPPORT: 01793 333212

Please read & understand this manual, payingattention to the safety instructions, before use.

The manufacturer reserves the right to change the product specification and livery according to

continued product improvements.

Images used are for illustration purposes only

INSTRUCTION MANUAL

CONTENTS

SPECIFICATION

IMPORTANT INFORMATION

GENERAL SAFETY INSTRUCTIONS

GET TO KNOW YOUR MACHINE

ASSEMBLY

FUELING

OPERATION

MAINTENANCE

STORAGE

TROUBLE SHOOTING

PARTS DIAGRAM & LIST

EC DECLARATION OF CONFORMITY

WARRANTY

NOTES

ASSEMBLY IS REQUIRED

This product requires assembly before use. See the “Assembly” section for instructions. Please check

that all parts required for the assembly of this machine are included. If for any reason you believe a part

for the assembly is missing or damaged, please contact us.

If you require any assistance with regards to the contents or operation of

your machine, please contact us:

TEL: 01793 333212

EMAIL: customerservice@handydistribution.co.uk

(MON –FRI 8.00AM TO 5.30PM EXCL. BANK HOLIDAYS)

You can register your machine at www.thehandy.co.uk

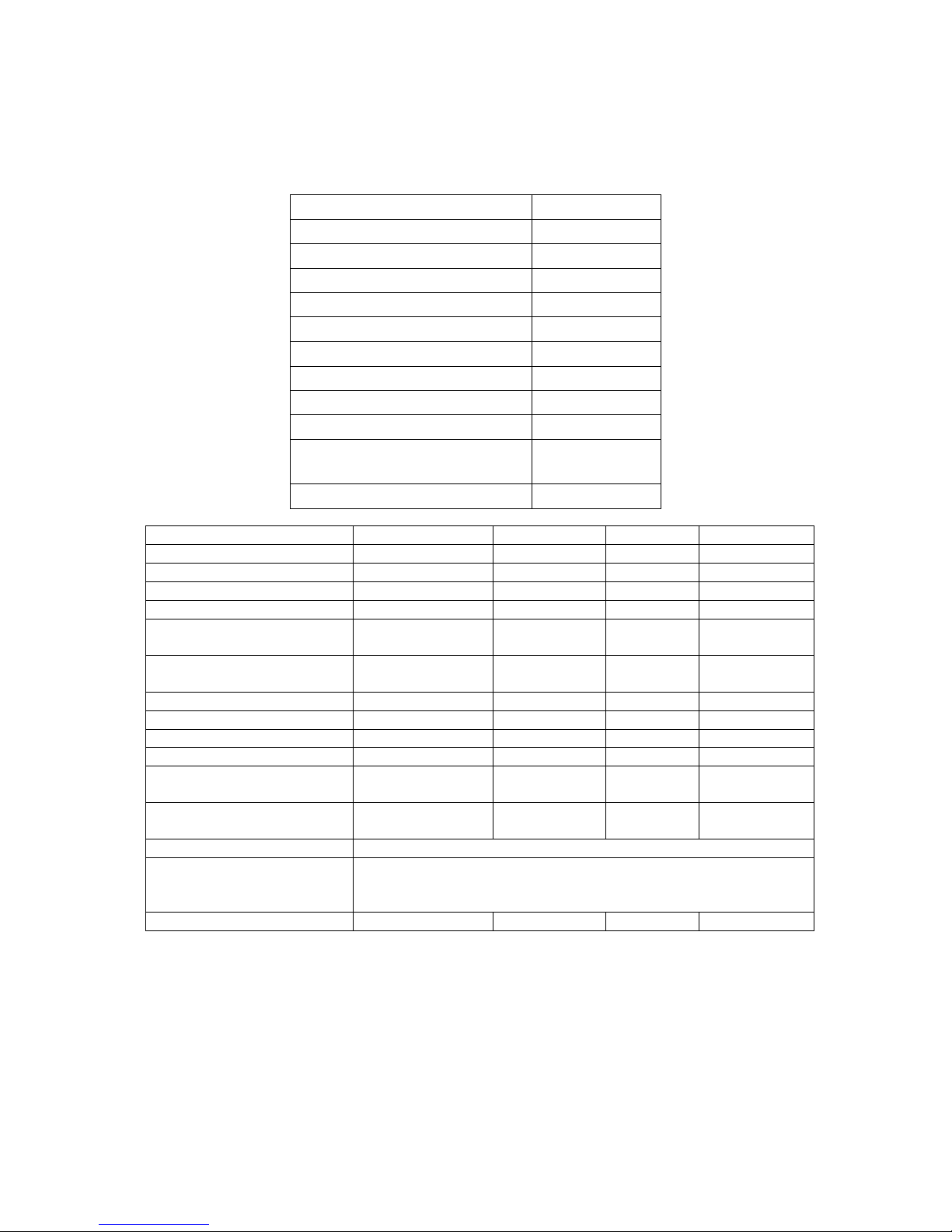

SPECIFICATION

The manufacturer reserves the right to change the product specification and livery according to continued

product improvements.

Model

THMT26

Product Number

1938176001

Engine

2-stroke, Air-cooled

Bore & Stroke

32 & 28mm

Number of cylinder

1

Engine Displacement

25.4cm3

Rated speed

7500rpm

Maximum torque speed

6500rpm

Maximum engine speed

10500rpm

Fuel Type

Unleaded Petrol

Fuel Mixture

Unleaded Petrol/2-Stroke Synthetic Oil

40:1

Fuel Tank Capacity

550ml

Brushcutter

Line Trimmer

Pruner

Hedgecutter

Cutting Diameter

254mm

400mm

19mm

Cutting Length

254mm

450mm

Chain Bar Type

3/8”

Shaft

Straight

Curve

Straight

Straight

Blades

3T

(Double Sided)

2

(Double Edged)

Spool Type

Bump Feed,

Twin Line

Line Diameter

2.4mm

Chain Pitch

3/8” 0.050

Chain Links

44

File Required

5/32”

Net Weight with Power Unit

(5.1kg Empty Tank)

7.0kg

6.05kg

7.1kg

7.3kg

Length with Power Unit

(103mm)

185mm

170mm

212mm

228mm

Declared Sound Power Level

112 dB(A)

Vibration

Front Handle: Idling 6.303 m/s2, Racing 5.323 m/s2

Rear Handle: Idling 6.128 m/s2, Racing 5.362 m/s2

Uncertainty: K=1.5 m/s2

Max Cutting Speed

6800 rpm

7000 rpm

6500 rpm

1500 rpm

IMPORTANT INFORMATION

INTENDED USE

The Multi-Tool is designed solely for domestic gardens, with annual use below 50 hours. This product is not

intended for commercial use. Generally acknowledged accident prevention regulations and enclosed safety

instructions must be observed. Only perform work described in these instructions for use, any other use is

incorrect. The manufacturer will not assume responsibility for damage or injury resulting from such use.

GENERAL SAFETY INSTRUCTIONS

Read and understand the owner’s manual and labels affixed to the product. Learn its application and

limitations as well as the specific potential hazards. Retain these instructions for future reference. The

operator is responsible for following the warnings & instructions in this manual and on the product.

STAY ALERT

Do not operate the machine while under the influence of drugs, alcohol, or any medication that could affect

your ability to use it properly. Do not use this machine when you are tired or distracted from the job at hand.

Be aware of what you are doing at all times. Use common sense.

WORKING PLAN

Plan your work schedule and allow plenty of time for rest. Use continuously for around 30-40 minutes per

session and take between 10-20 minutes rest between work sessions. Also try to keep total amount of work

performed in a single day under 2 hours or less.

AVOID DANGEROUS CONDITIONS

Make sure there is adequate surrounding workspace. Cluttered areas invite injuries. Keep your work area clean

with sufficient light. Keep the area around the machine clear of obstructions, grease, oil, rubbish and other

debris which could cause persons to fall onto moving parts.

SAFE TRANSPORTATION

Always carry the machine and attachments with the supplied safety guards. If transporting by vehicle, ensure

is it secured horizontally, with the fuel tank at the lowest point, to prevent turnover, fuel spillage or damage.

INSPECT YOUR MACHINE

Check all bolts, nuts, and screws for tightness before each use, especially those securing guards and drive

mechanisms. Vibration during use, may cause these to loosen. Always check to see that all other tools or

equipment are removed from the working area before turning it on. Replace damaged, missing or failed parts

before using it. Warning labels carry important information. Replace any missing/damaged warning labels.

DRESS PROPERLY

Do not wear loose clothing, gloves, scarfs, neckties or jewellery (rings, wrist watches), which can be caught in

moving parts. Protective gloves and non-skid heavy-duty footwear are highly recommended when working.

Wear a face or dust mask if the operation is dusty. Always wear safety glasses/goggles and/or face shields.

Everyday eyeglasses have only impact resistant lenses; they are not safety glasses/goggles. Wear protective

hair covering to contain long hair, preventing it from getting caught in machinery.

CAUTION HOT

Do not touch hot parts of the machine, burn injuries may occur.

DO NOT SMOKE

Do not smoke when using the machine & caution when handling fuel. We recommend you fuel the machine at

least 3 metres away from where you wish to work, in case any spilt fuel ignites when starting the engine.

AVOID ELECTRICAL SHOCK

Do not operate near underground electrical cables, telephone lines, pipes or hoses.

USE THE SHOULDER HARNESS

Always use a shoulder harness. Adjust the shoulder harness to a comfortable operating position before

starting. Maintain a firm grip on both handles. Keep your area clear of the machine cutting area.

DO NOT OVERREACH

Keep proper footing and balance at all times when using the machine. Serious injury could occur if the moving

parts are unintentionally contacted. Do not store anything above or near the machine, where anyone might

stand on the machine to reach them.

AVOID INJURY FROM UNEXPECTED ACCIDENT

Keep hands & feet out of the way of all moving parts. Do not place any part of your body or any tool e.g. in the

machine during operation. Do not place any moving parts on the ground during start up.

BLOCKAGES

Do not attempt to remove a blockage from a jammed machine before first switching the engine off.

KICKBACK

The Pruner attachment is supplied with a low KICKBACK chain, however sometimes kick back can occur, so

always hold the unit firmly in two hands. The Kickback danger zone on your Pruner is the upper part of the

nose of the guide bar. Never saw using this part of the guide bar, which poses a significant risk for kickback.

DO NOT FORCE TOOL

Always work within the rated capacity. Do not use machine for a purpose for which it was not intended.

NEVER LEAVE MACHINE RUNNING UNATTENDED

Do not leave the machine unattended until it has come to a complete stop.

MAINTAIN YOUR MACHINE WITH CARE

Clean the machine immediately after use. Keep clean to ensure it operates to its full and safest performance.

When maintaining, only manufacturer original replacement parts. The use of non-original manufacturer parts

may invalidate your warranty.

PROTECT THE ENVIRONMENT

Take left over materials & fluids to an authorised collection point or follow the stipulations in the country

where the machine is used. Do not discharge into drains, soil or water.

STORE IDLE EQUIPMENT

When not in use, the machine should be stored in a dry location. Keep the machine away from children and

others not qualified to use it.

SAFETY SYMBOLS

Safety alert symbol. Used to alert you to potential

personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in serious injury.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in serious injury.

CAUTION

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury.

CAUTION

Used without the safety alert symbol indicates a

potentially hazardous situation which, if not

avoided, may result in property damage.

1 2 3 4 5 6 7

1. Read the owner’s manual prior to operating the machine

2. Wear head, eye and ear protection

3. Wear non-skid heavy duty footwear.

4. Wear protective electrically non-conductive gloves.

5. Beware of thrown objects.

6. Warning/Attention

7. Keep all children, bystanders and animals 15 metres away from Danger Zone.

NEVER MODIFY THE MACHINE.

The warranty supplied with the product is void if you make any modification to the machine or if you do not

observe the proper usage guidance written in this manual.

GET TO KNOW YOUR MACHINE

Image used for illustration purposes and may differ slightly from your item.

FUEL TANK

PRIMER

BULB

BRUSHCUTTER

LINE TRIMMER

GUARD

CHAIN COVER

CHAIN OIL

TANK &

CAP

PETROL

POWER

UNIT

CHAIN

GUARD

FUEL TANK

CAP

CHOKE

LEVER

THROTTLE

TRIGGER

SAFETY

LEVER

ON/OFF

SWITCH

P-HANDLE

HARNESS

HANGER

QUICK

JOINT

AIR FILTER

HOUSING

GUARD

PRUNER

HEDGECUTTER

GUIDE BAR &

CHAIN

3T

BLADE

DOUBLE

BLADE

BLADE

COVERS

SPOOL & NYLON

LINE

ASSEMBLY

LINE TRIMMER ATTACHMENT

GUARD

Place the guard onto the bent shaft of the Line Trimmer Attachment. The bracket is placed on the top of the

shaft and the guard sits underneath. They are secured with two 4mm Allen Key Bolts. Tighten until secure.

(Fig 1)

NYLON HEAD

The Nylon Head is secured to the shaft, by rotating clockwise. Do so until you reach the end of the thread

(Fig 2). Secure the large nut with a suitable Spanner or Mole Grip and hand tighten until secure. (Fig 3)

BRUSHCUTTER ATTACHMENT

GUARD

Place the plastic guard onto the small metal guard & secure with three 5mm Allen Key bolts. (Fig 4).

METAL BLADE

Remove the Blade Nut, Cup & Clamp Washers. The Stepped Washer must remain (Fig 5).

Now place the blade onto the Stepped Washer, ensuring the step of the washer is placed into the hole of the

blade (Fig 6). Sit the Clamp Washer onto the blade (Fig 7).

Fig 1

Fig 2

Fig 3

Fig 4

Fig 6

Fig 7

CUP

WASHER

CLAMP

WASHER

STEPPED

WASHER

BLADE NUT

Fig 5

Sit the Cup Washer onto the Clamp Washer (Fig 8). Thread the Blade Nut onto the shaft. Please note this is a

Left-Hand threaded nut and should be rotated anti-clockwise, to secure (Fig 9).

Align the locking hole within the Metal Guard and Stepped Washer (Fig 10). Insert an Allen Key to stop the

shaft rotating (Fig 11) and firmly tighten the Blade Nut with a Spanner (Fig 12).

PRUNER ATTACHMENT

You will need to attach the Pruner head to the shaft (Fig 13).

Remove the 5mm Allen Key Bolts located in the Head and Clamp of the Pruner

Insert the Shaft into the Head, ensuring the splined driveshaft is housed into the splines of the Head.

Align the Fixing Hole located on the shaft with the hole within the Head and tighten with the 5mm Allen Key

Bolt, until secured.

Insert the second 5mm Allen Key Bolt into the clamp and tighten until secure.

1. Shaft

2. Pruner Head

3. Fixing Hole

4. Clamp

5. 5mm Allen Key Bolt x2

WARNING

The Chain has very sharp edges. Use protective gloves for safety.

WARNING

Ensure the Chain is placed in the correct direction.

Fig 8

Fig 9

Fig 10

Fig 11

Fig 12

Fig 13

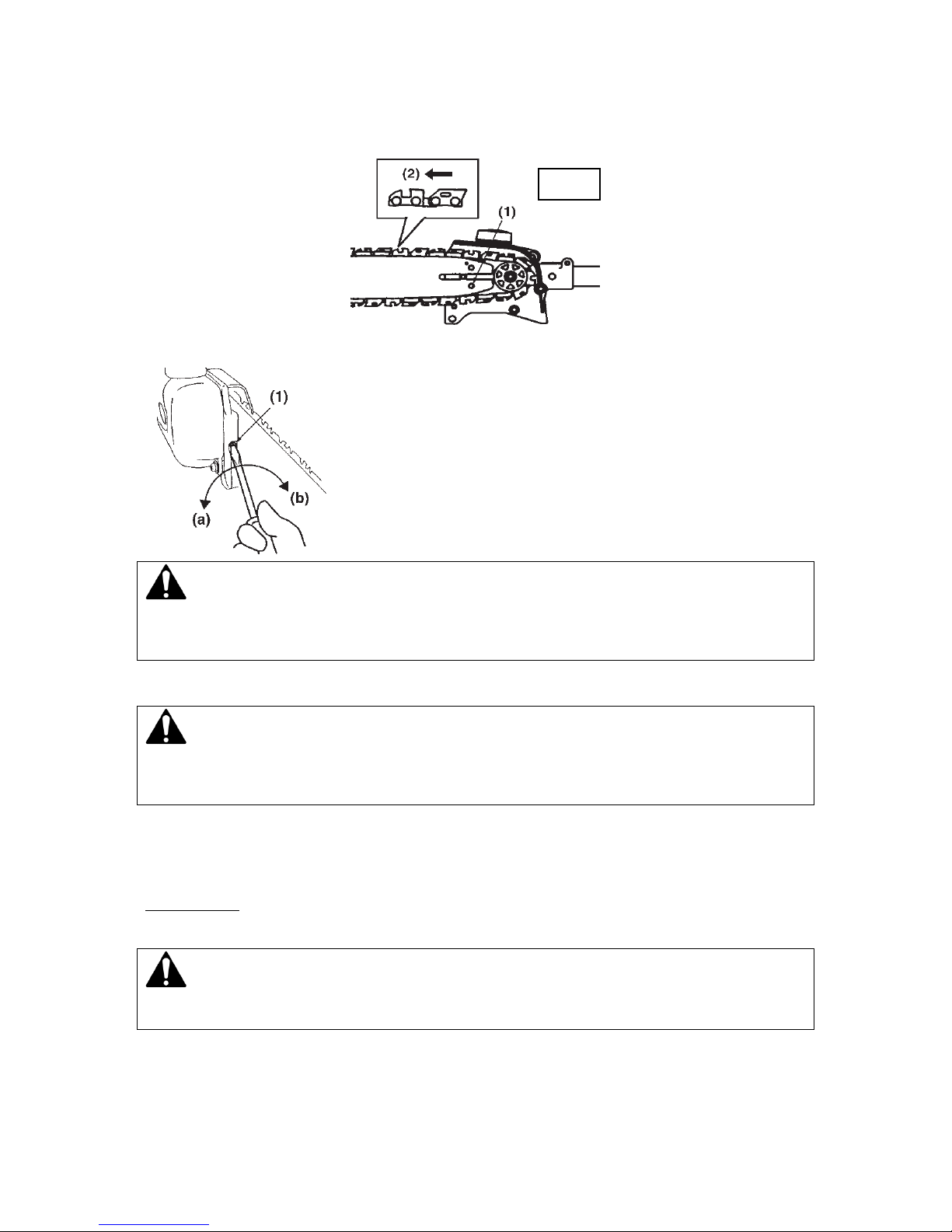

Check the Chain has a smooth rotation and correct tension with your hand (Always where safety gloves). If

necessary, adjust. The tensioner arm should be located into the lower hole (1) of the guide bar to allow full

adjustment.

Adjust the chain tension by turning the tensioner screw. You should be able to pull the chain away from the

guide bar, 5-6mm or pull the chain along the guide bar by hand.

1. Chain Tension Adjuster Screw

a. Loosen

b. Tighten

WARNING

It is important to maintain the proper chain tension. Rapid wear of the Chain/Guide Bar or the Chain coming

off easily can be caused by improper tension. A new chain must be tensioned more often than an older

chain, which has been used for some time.

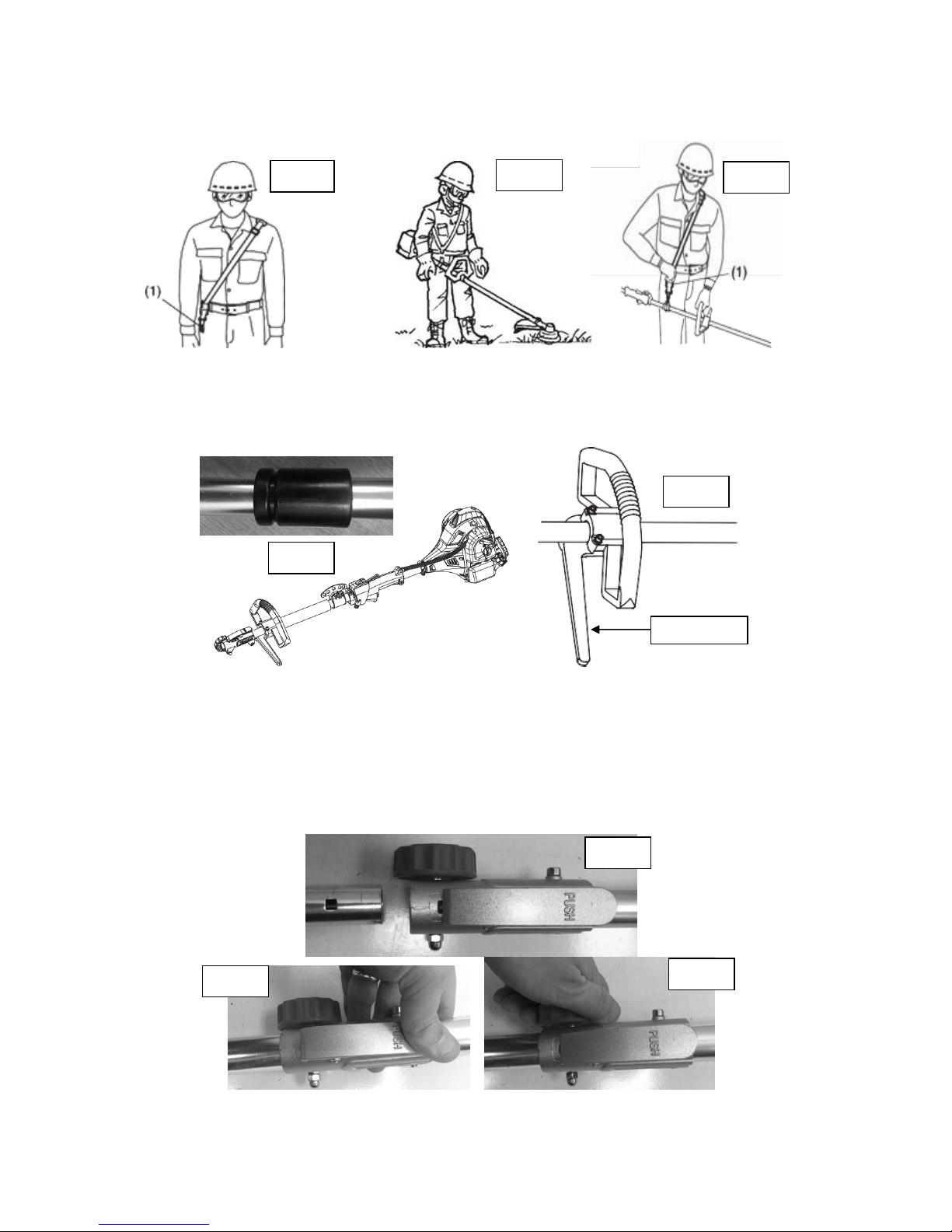

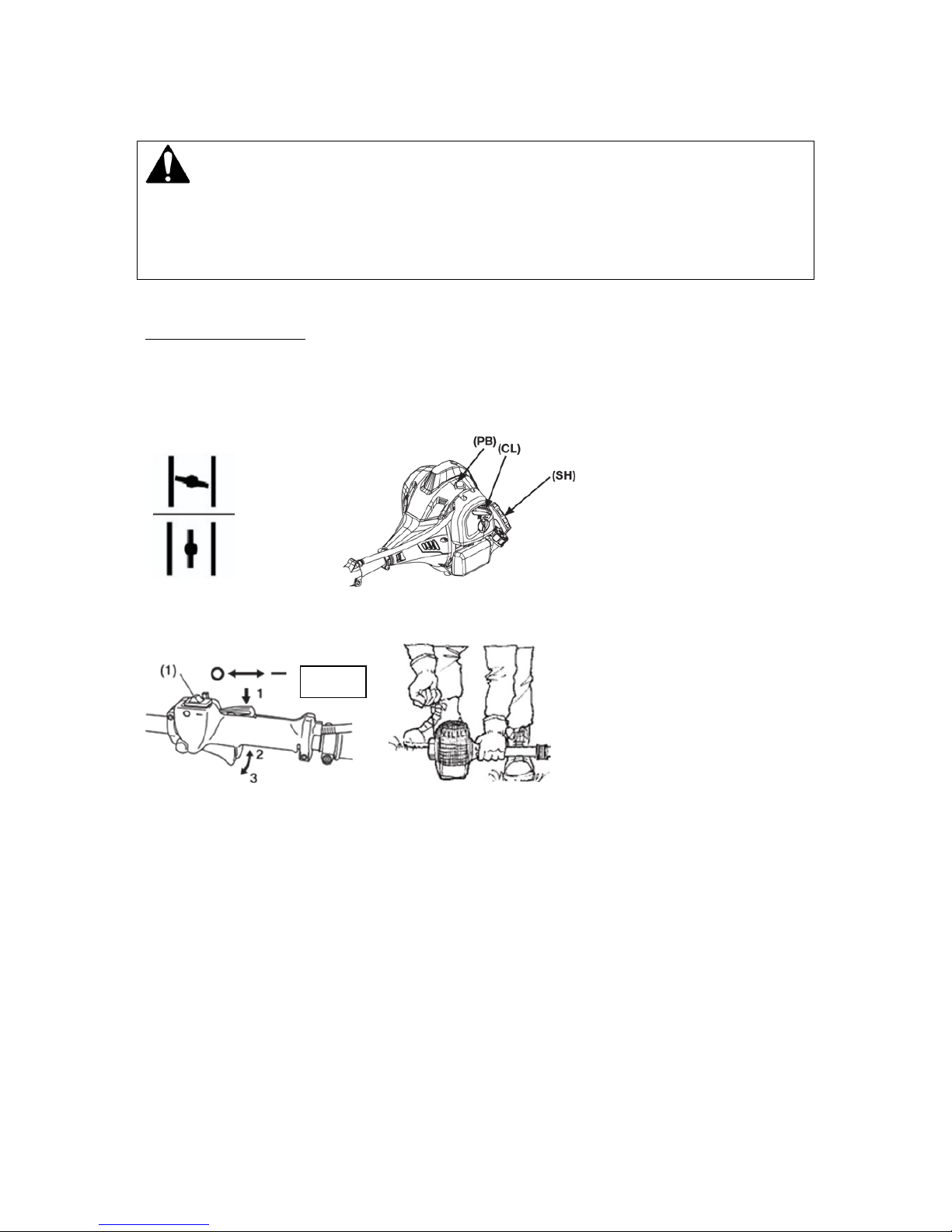

SHOULDER STRAP

WARNING

ALWAYS wear the provided Shoulder Strap, when operating. Make sure the Shoulder Strap is hooked

securely to the Harness Hanger. Incorrect use can cause the machine to be unbalanced and may cause injury

to yourself of bystanders.

Wear the provided Shoulder Strap without twists, with the connecting hook (Fig 17) on your right side. Hook

the Shoulder Strap to your chosen locating holes on the Harness Hanger. Adjust the length of the Shoulder

Strap to enable the cutting blade to be parallel to the ground when you are in your normal working position

(Fig 18). This provides the most effective and comfortable operating position.

QUICK RELEASE

The Shoulder Strap is equipped with a Quick Release devise. To release the machine from the harness in an

emergency situation, please follow the below steps:

WARNING

Always check the correct operation of the Quick Release before operating the machine. Make sure you hold

the machine securely, prior to checking the Quick Release mechanism.

Fig 14

While holding the machine securely with your left hand, pull the red tab (1) and the Shoulder Strap will release

from the machine. (Fig 17)

P-HANDLE

Mount the handle onto the Handle Seat (Fig 18) Insert and tighten the bolts supplied to secure the handle to

the shaft in the desired position. Ensure the leg guard of the Loop Handle is on the left of the shaft and in the

direction as per the arrow on the grip. (Fig 19)

QUICK JOINT

The Quick Joint coupler allows you to safely attach the different attachments to the power unit. To attach your

chosen attachment to the power unit, follow the below steps.

1. Loosen the Handwheel (Fig 22)

2. Align the attachment with the power unit (Fig 20)

3. Insert the attachment and depress the coupler lever. (Fig 21)

4. Ensure the attachment securing hole is aligned with the couple lever leg and secure.

5. Tighten the Handwheel until secure. (Fig 22)

Fig 15

Fig 16

Fig 17

Fig 18

Fig 19

Leg Guard

Fig 20

Fig 21

Fig 22

FUELING

Fuel & its vapors are very flammable. Do not use or fuel the machine near a flame, sparks or while smoking.

Allow the engine to cool for more than 3 minutes, before re-fueling. Never fuel the machine with the engine

running. Fuel the engine at least 3 metres away from your work area. Always fuel your machine outdoors.

FUEL MIXTURE

The machine has been designed to use 40:1 unleaded petrol to 2-stroke synthetic oil fuel ratio.

The fuel mixture should be shaken prior to entering the machine fuel tank.

40:1 Fuel Mixture Ratio

Unleaded Petrol –litre

Two-Stroke Synthetic Oil - ml

1

25

2

50

3

75

4

100

5

125

Use good quality unleaded fuel. Fuel which is older than 30 days old can become stale and cause acid & gum

deposits in the fuel system or essential carburettor components. This could result in starting issues which

would not be covered by your manufacturer’s warranty.

To keep fuel fresh, we recommend you use SURE-START FUEL ADDITIVE (HP-199) from Handy Parts. A fuel

additive added to your fuel at the time of mixture, will help make your machine easier to start, extend the

shelf life of your fuel mixture for up to two years, keeps the carburettor & engine clean, plus reduces emissions

and increases fuel economy. A 250ml bottle of SURE-START FUEL ADDITIVE will treat 25 litres of fuel mix

Only use 2-stroke air cooled engine oil. DO NOT USE automotive or marine oil.

It is recommended that you use a Fuel Mixing Bottle, to ensure the correct fuel mixture is used with your

machine. We recommend HANDY PARTS –FUEL MIXING BOTTLE (HP-120).

Unscrew the fuel cap slowly and fill the fuel tank with your fuel mixture to a maximum of 80% capacity. This

will allow the fuel tank expansion. Fasten the fuel cap tightly, being careful not to cross-thread. This will also

prevent loosening through vibration during use.

Wipe away any spillage, with an appropriate material.

If the machine has continued leaks, the product should not be started. Never use the machine with damaged

ignition cable or spark plug cap, as there is a risk of sparks.

IMPORTANT

Ensure that any stored petrol/oil mixture is clearly marked in a separate appropriate canister for a

maximum of 4-6 weeks if not mixed with a fuel additive. If the machine is not going to be used for a long

period, drain the mixture from the fuel tank, start the engine and drain the carburetor of any remaining fuel.

(See Maintenance for further instruction). Dispose of any unwanted 2-stroke mixture at an authorised

recycling point.

FUELING THE MACHINE

Place the machine onto a solid flat surface.

Ensure the engine is not running, before refueling.

Unscrew the fuel cap slowly and fill the fuel tank with your fuel mixture to a maximum of 80% capacity. This

will allow the fuel tank to expand.

Fasten the fuel cap tightly, being careful not to cross-thread. This will also prevent loosening through vibration

during use. Wipe away any spillage, with an appropriate material.

If the machine has continued leaks, the product should not be started. Never use the machine with damaged

ignition cable or spark plug cap, as there is a risk of sparks.

Operating the engine with insufficient oil within your fuel can have catastrophic consequences. Any failure

caused by insufficient oil, will not be covered by the manufacturer’s warranty, supplied with this machine.

OPERATION

DANGER

The DANGER ZONE on the output of the machine must be respected, to avoid serious injury. Do not allow

anyone to enter the operating DANGER ZONE with you. The danger zone is an area 15 metres in radius.

Insist that persons in the RISK ZONE beyond the danger zone wear eye protection from thrown

objects. Do not operate if the user or bystanders have insufficient protection.

DANGER ZONE WITHIN 15 METRES –RISK ZONE GREATER THAN 15 METRES

POWER UNIT

STARTING A COLD ENGINE

Once you are happy that your Multi-Tool has been assembled & fueled correctly, you are now in a position to

start the machine.

During the first 10 hours of work, run the engine at moderate speed.

Place the Power Unit onto the floor, with the fuel tank at its lowest. We recommend you use a concrete or

similar surface to avoid slippage.

Move the ON/OFF switch to the ‘I’ position (Fig 23).

Move the Choke Lever (CL) left to the Closed position (Towards the cutting blade).

Push the clear Primer Bulb (PB), 5-10 times until the fuel mixture fills the bulb.

Place your left hand on the handle shaft to apply downward pressure.

Pull the Recoil Starter Handle (SH), with a smooth rapid pull for a strong spark, until the engine fires, but

immediately cuts out. (We call this a false start).

Apply downward pressure onto the Safety Trigger (1) and pull up the Trigger (2). This will automatically release

the Choke Lever to the Open position. Release the Safety Trigger and Trigger (3)

Pull the Recoil Starter again, with a smooth rapid pull.

The engine should now start. Allow the engine to run for 10 seconds on normal tick over before pulling the

trigger to increase the engine revs and move the cutting blade.

NOTE

Over choking of the engine, can cause the engine to be difficult to start due to excess fuel. When the engine

fails to start after several attempts, remove the spark plug and dry it with the appropriate material.

Choke Closed

Cold Start

Position

Choke Open

Warm Start or

Run Position

Fig 23

STARTING A WARM ENGINE

Place the Power Unit onto the floor, with the fuel tank at its lowest. We recommend you use a concrete or

similar surface to avoid slippage.

Move the ON/OFF switch to the ‘I’ position.

Ensure the Choke Lever is to the right in the Open position.

Pull the Recoil Starter again, with a smooth rapid pull. The engine should now start, and you are free to

operate the machine.

WARNING

The product is equipped with a centrifugal clutch mechanism, so the cutting blade should not move on start

up or tick over. If the cutting blade does move, stop the engine immediately and refer to the Trouble

Shooting section of this manual.

STOPPING THE ENGINE

•Release the throttle trigger and allow the engine to idle for a few moments.

•Move the ON/OFF switch to the ‘O’ position.

WARNING

Attachments may continue to rotate for a few seconds after the engine has stopped.

GENERAL USE

WARNING

Prior to using the Multi-Tool, ensure all nuts, bolts & screws are securely tightened.

Always have a firm footing and use two hands.

Always position the Power Unit on your right side, with all attachments. Using it on the left side will expose

the user to the exhaust. Hot surfaces can result in burns. The trigger handle should be positioned at waist

height.

Operate the trigger with your right hand & hold the P-handle with your left hand.

The trigger increases and decreases the power of the engine to the attachment, increasing the

revolution/reciprocation of the attachment.

HEDGECUTTER

To adjust the angle of the Hedge cutter, pull pin 1 and depress levers A & B, you can now release the pin.

Rotate the Hedgecutter head to the desired angle & fix the locking lever to the gear ring, ensuring the teeth

are locked.

Always have a firm footing and use two hands to hold the machine

It is advisable to cut a hedge from the bottom up, sweeping the cutter head in an arc as you move along the

hedge. The double-edged cutter blades allow cutting of your hedge in both directions.

To cut the top of the hedge, adjust the cutter head to a horizontal position. Hold the cutter head at an angle of

0-10 degrees as you sweep the head in an arc across the top of your hedge, towards the outside to allow

cuttings to fall to the ground.

1

B

A

Pay special attention to hedges which are positioned along wire fencing. If the cutting blades contact the

fence, damage may occur. If the blade meets a stone, wire or other foreign object, stop immediately and check

for any damage to the blades immediately.

Do not attempt to remove any twigs or branches jammed in the blades, without first turning the engine off.

Always check for any damage before each use and replace damaged blades immediately, with an approved

replacement part.

Always fit the supplied blade guard when the Hedgecutter is not in use.

BRUSHCUTTER

WARNING

Always wear safety goggles or glasses to protect your eyes. Never lean over the rotating head. Stones or

other debris could be thrown towards your face and cause serious personal injury.

Always keep the guard in place.

Operate with the power unit on your right side, using the Shoulder Strap. Always keep a firm grip with both

hands during operation. The machine should be held at a comfortable position, with the trigger handle at hip

height. Adjust the shoulder strap to suit.

Maintain a firm footing in case the machine hits a solid object & kicks back. Do not use the Brushcutter near

fencing, posts, buildings or other immoveable objects. If a hard object is struck, immediately stop the machine

and inspect for damage.

Use the front left side of the cutting rotation. Guide the blade from left to right, with the blade tilted slightly

towards the left.

Be sure that the blade and holder are positioned and secured correctly. If assembled incorrectly, excessive

vibration made be felt and the machine must be stopped immediately, and the correct assembly instructions

followed.

Do not attempt to cut foliage which is too long. We recommended you cut long foliage in stages. The blade

may become seized by foliage if the engine speed is too low or you attempt to cut too deep into the growth.

Adjust the engine speed and cut in stages to avoid stoppages.

WARNING

DO NOT contact the metal blade with utility wires, metal stakes, rubber, masonry, rocks, fences, and trees.

DANGER

Rocks & metal can dull or damage a blade. Wires can wrap around the blade head or be thrown in the air.

DO NOT cut with a dull, cracked or damaged metal blade.

Before cutting, inspect for obstructions. If an obstruction cannot be removed, mark its location clearly so

you can avoid it during operation.

SCYTHING WEEDS

This is cutting by swinging the blade in a level arc. It can quickly clear areas of field grass and weeds. Scything

should not be used to cut large, tough weeds or woody growths.

Scything can be done in both directions, or just in one way which results in the debris being thrown away from

you. This is done by using the side of the blade that it is rotating away from you. Tilt the blade downwards

slightly, on this same side. You will be hit by some debris if you scythe in both directions

LINE TRIMMER

WARNING

Always wear safety goggles or glasses to protect your eyes. Never lean over the rotating head. Stones or

other debris could be thrown towards your face and cause serious personal injury.

Always ensure the guard is in place.

Always keep a firm grip with both hands during operation. The machine should be held at a comfortable

position. Adjust the shoulder strap to suit. Maintain a firm footing in case the machine hits a solid object &

kicks back

Cut tall grass from the top down to prevent grass wrapping around the shaft housing & strong head, which

may cause overheating and damage. If grass becomes entangled, stop the engine completely and remove the

grass.

FEED NYLON LINE

Note: A full spool of trimmer line is included with this trimmer from new.

Feed out new line by pressing the trimmer head firmly on the ground with the trimmer turned on and the

trimmer head spinning. Run the trimmer for a few seconds without trimming to allow the trimmer line to be

cut to the correct length. (Do not hit the ground with excessive force, damage may occur not covered under

warranty)

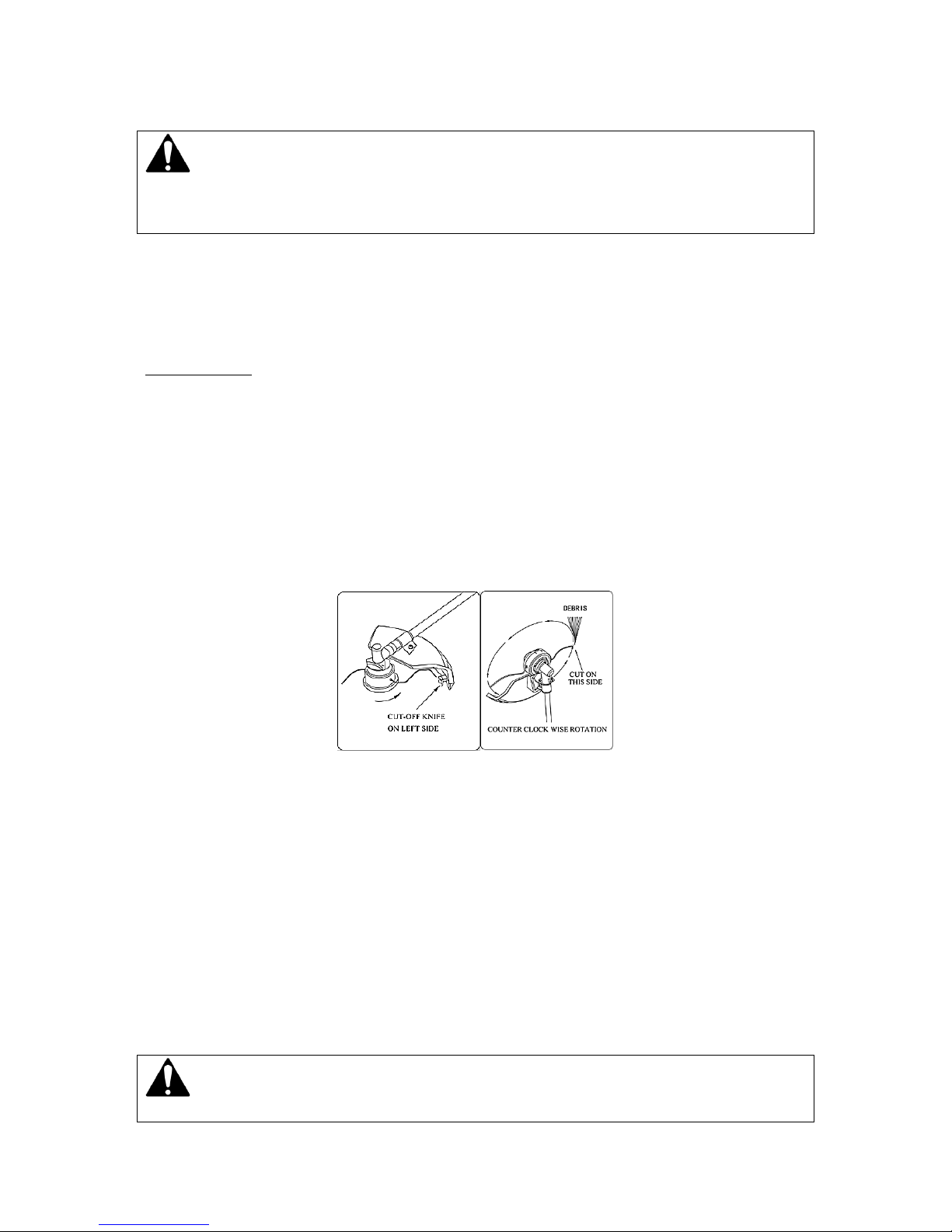

The line trimmer head rotates in an ANTI-CLOCKWISE direction. The knife, located on the left side of the guard,

ensures your nylon line is operating at the correct length for optimum trimming.

NOTE: Nylon line which is too long or the incorrect diameter (Recommended 2.4mm), will cause excess wear

to the engine and clutch components, not covered by the manufacturer’s warranty.

It is recommended that the head is tilted at a 20o angle, so the nylon line cutting circle is moving away from the

user and guard/shield. This will enable debris to be thrown away from the user.

TRIMMING

This is feeding the trimmer carefully into the material you wish to cut. Tilt the head slowly to direct debris

away from you. If cutting up to a barrier such as fence, wall or tree, approach from an angle where any debris

ricocheting off the barrier, will fly away from you. Move the line head slowly until the grass is cut right up to

the barrier, but do not jam (over-feed) the line into the barrier.

If trimming up to a wire mesh or chain linked fence, be careful to feed only up to the fence. If you go too far,

the line will snap off around the fence.

Trimming can be done to cut through weed stems, one at a time. Place the trimmer line head near the bottom

of the weed, never high up, which could cause the weed to chatter and catch the line. Rather than cut the

weed right through, just use the very end of the line to wear through the stem slowly.

SCALPING AND EDGING

Both of these are done with the line head tilted at a steep angle.

Scalping is removing top growth leaving the earth bare.

Edging is trimming the grass back where it has spread over a path or driveway.

During edging and scalping, hold the unit at a steep angle and in a position where the debris and any dislodged

dirt and stones will not come back towards you, even if it ricochets off the hard surface.

WARNING

DO NOT use a metal blade for scalping or edging

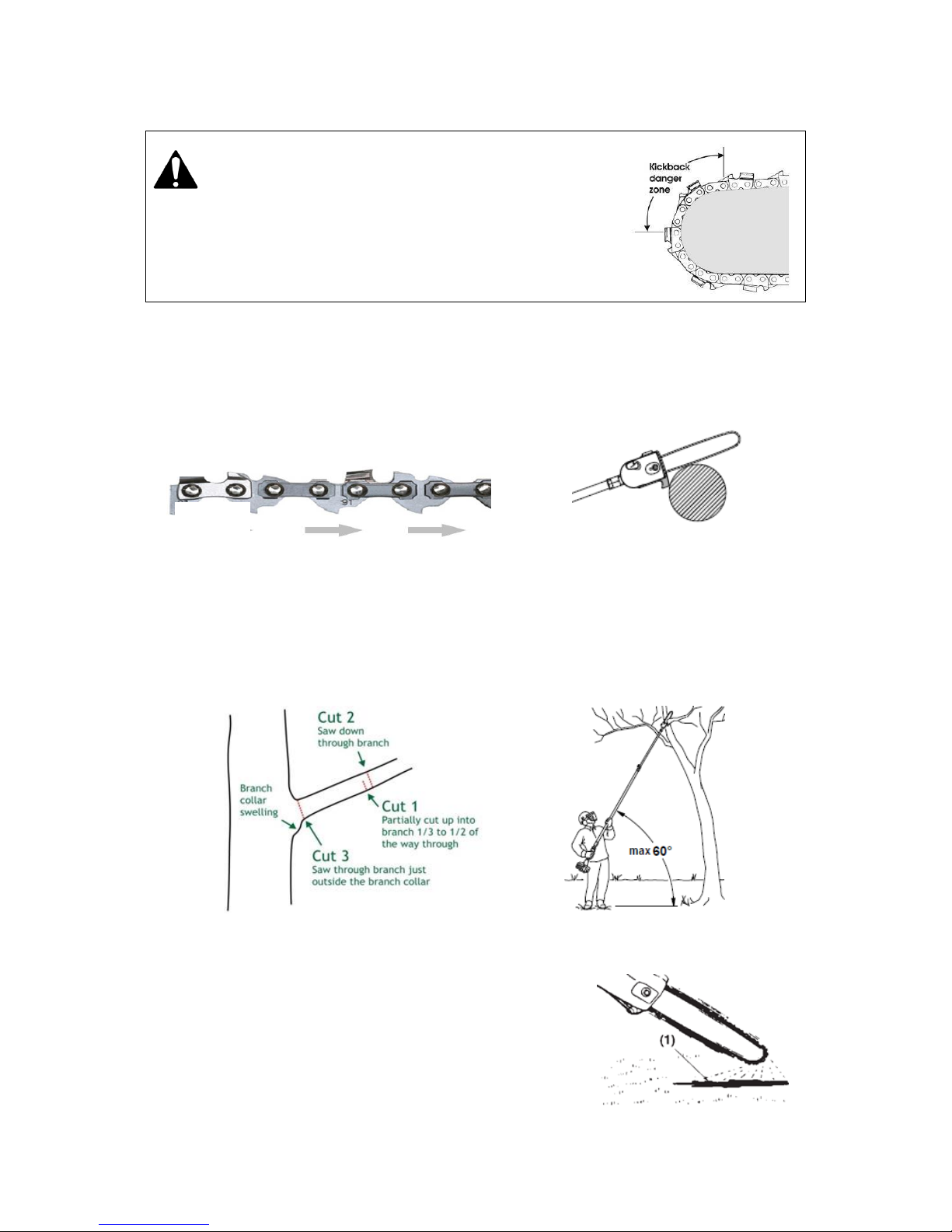

PRUNER

WARNING

The Pruner is supplied with a low KICKBACK chain, however sometimes kick

back can occur, so always hold the unit firmly in two hands. The Kickback

danger zone on your Pruner is the upper part of the nose of the guide bar.

Never saw using this part of the guide bar, which poses a significant risk for

kickback.

CHAIN OIL

Chainsaw oil should always be used with the Pruner attachment. We recommend Handy Parts Chainsaw Oil

(HP-177). Remove the oil cap from the canister, fill until 80% full and replace oil cap.

Position the hook located on the bottom of the head against the branch, to reduce the risk of the pruner

jerking forward.

Ensure the chain is running in the correct direction.

Thin branches can be removed with a single cut, but if the branch is long, it is preferable to cut it in several

pieces, moving towards the main trunk of the tree. Always check for any damage before each use and replace

a damaged chain immediately, with an approved replacement part. Before every use, check the level of the

chain oil in the reservoir. During use, check the tension of the chain. (See Maintenance Section for Instruction)

Always fit the supplied blade guard when the Pruner is not in use. For larger branches, the 3-point method

should be used to prevent breakage. Do not work at an angle higher than 60o, there is a danger of being

injured by branches falling without warning. Be careful not to trip over grounded branches.

CHECKING OIL SUPPLY

After starting the engine, run the chain at medium speed over a piece of cardboard or paper. Chain oil should

be scattered off as shown (1).

NOTE: The oil reservoir has capacity to provide 40 minutes of cutting time

approximately. This will depend on oil flow rate. Be sure to refill the

reservoir to ensure your chain is constantly lubricated. Increasing the oil

flow rate will increase the oil consumption, requiring frequent checks on

the oil reservoir.

Cutting

Direction

Top

3-point cutting method for larger branches

Do not work at an angle over 60O

Position cutting

hook against branch

ADJUSTING THE OIL FLOW RATE

WARNING

Never fill the oil reservoir or adjust the oiler with the engine running.

The guide bar and chain are automatically lubricated by a pump that operates when the chain is in motion. The

pump is set at the factory to deliver a minimum flow rate, but it can be adjusted. A temporary increase in oil

flow is often desirable when cutting hard wood.

Adjust the pump as follows:

Stop the engine and make sure the ON/OFF Switch is in the “O” position.

Place the unit on its side with the oil reservoir up.

With a screwdriver, push in on the oil flow adjusting screw and turn in the desired direction (there are three

incremental settings).

1. Oil Tank

2. Chain Cover

a) Clockwise –Decrease Lubrication

b) Anti-Clockwise –Increase Lubrication

c) Middle

IMPORTANT

The oil flow adjusting screw must be pressed in slightly to turn. Failure to do so, could damage the pump

and screw.

MAINTENANCE

Only undertake maintenance and service work described in this manual. More extensive work must be

carried out by an authorised service dealer. (Visit www.thehandy.co.uk to find your nearest).

IMPORTANT:

If a part needs replacement, only use parts that meet the manufacturer’s specifications. Replacement parts

that do not meet specifications, may result in a safety hazard or poor operation.

Engine repairs must be made by an approved service dealer.

POWER UNIT

WARNING

Prior to undertaking any inspection or maintenance, ensure the engine has stopped and completely cooled.

Contact with moving cutting heads or hot exhausts may result in a personal injury.

CARBUETTOR

The carburettor governs the engine’s speed via the throttle control. Air and fuel are mixed in the carburettor.

The air/fuel mixture is adjustable as is the engine speed. Correct adjustment is essential to get the best

performance from the machine. The T-screw regulates the throttle setting at idle speed, H-screw the max

speed and L-screw the air/fuel mix. Special tooling is required and should be undertaken by your approved

service dealer.

AIR FILTER

Accumulated dust in the air filter will reduce engine efficiency, increase fuel consumption and allow abrasive

particles to pass in the engine. Remove & clean the air filter regularly to ensure optimum performance.

Remove the air filter cover, by releasing the securing winged screw from the front of the cover. Lift off the

cover. Remove the air filter from the housing. Tap the filter to remove light surface dust. Heavy deposits

should be brushed off. If deposits cannot be removed, replace air filter.

FUEL FILTER

Check the fuel filter periodically, but be careful not to allow dust to enter the fuel tank.

The fuel tank is fitted with a filter, which is situated at the free end of the fuel pipe and can be extracted by

using a piece of hooked wire.

If the filter is dirty on inspection, replace it immediately with an approved replacement part.

If the inside of the fuel tank is dirty, rinse out with petrol.

SPARK PLUG –BM6A

Check the Spark Plug after every 10-15 hours of use.

Remove the Spark Plug cover with a crosshead screwdriver and the rubber cap.

Using the Spark Plug Spanner supplied, remove the Spark Plug by turning it anti-clockwise.

Clean & adjust the electrode gap to 0.6-0.7mm

If the Spark Plug is visibly damaged or worn, replace immediately (See Specification for details)

Install the new/cleaned Spark Plug to finger tightness, before fully tightening with the spanner.

Replace the spark plug with a similar make & model, every 50 hours or once a year (whichever comes first).

EXHAUST

WARNING

Periodically inspect the exhaust for loose fastenings, damage or corrosion. If any sign of leakage is found,

stop using the machine and have inspected by an approved service dealer. Failure to do so, may result in the

engine catching fire and personal injury.

AIR INTAKE COOLING VENTS

WARNING

Never touch the cylinder, exhaust or spark plug with your bare hands immediately after stopping the engine.

The engine can become very hot when in operation and doing so could result in severe burns.

0.6 - 0.7mm

If waste gets stuck and causes blockages around the air intake cooling vent (1), it may cause the engine to

overheat and that in turn may cause mechanical failure.

BRUSHCUTTER

GEAR HEAD LUBRICATION

The gearhead is filled with multi-purpose lithium grease. Regularly check the quantity and fill where necessary.

Remove the grease-nipple from the gearhead and fill appropriately. Refit when complete.

BLADE SHARPENING

Never attempt to sharpen the blade. It is reversible, so should be turned over when blunt. The blade must

remain balanced; an unbalanced blade will cause excessive vibration through the machine. Always check for

any damage before each use and replace a damaged blade immediately, with an approved replacement part.

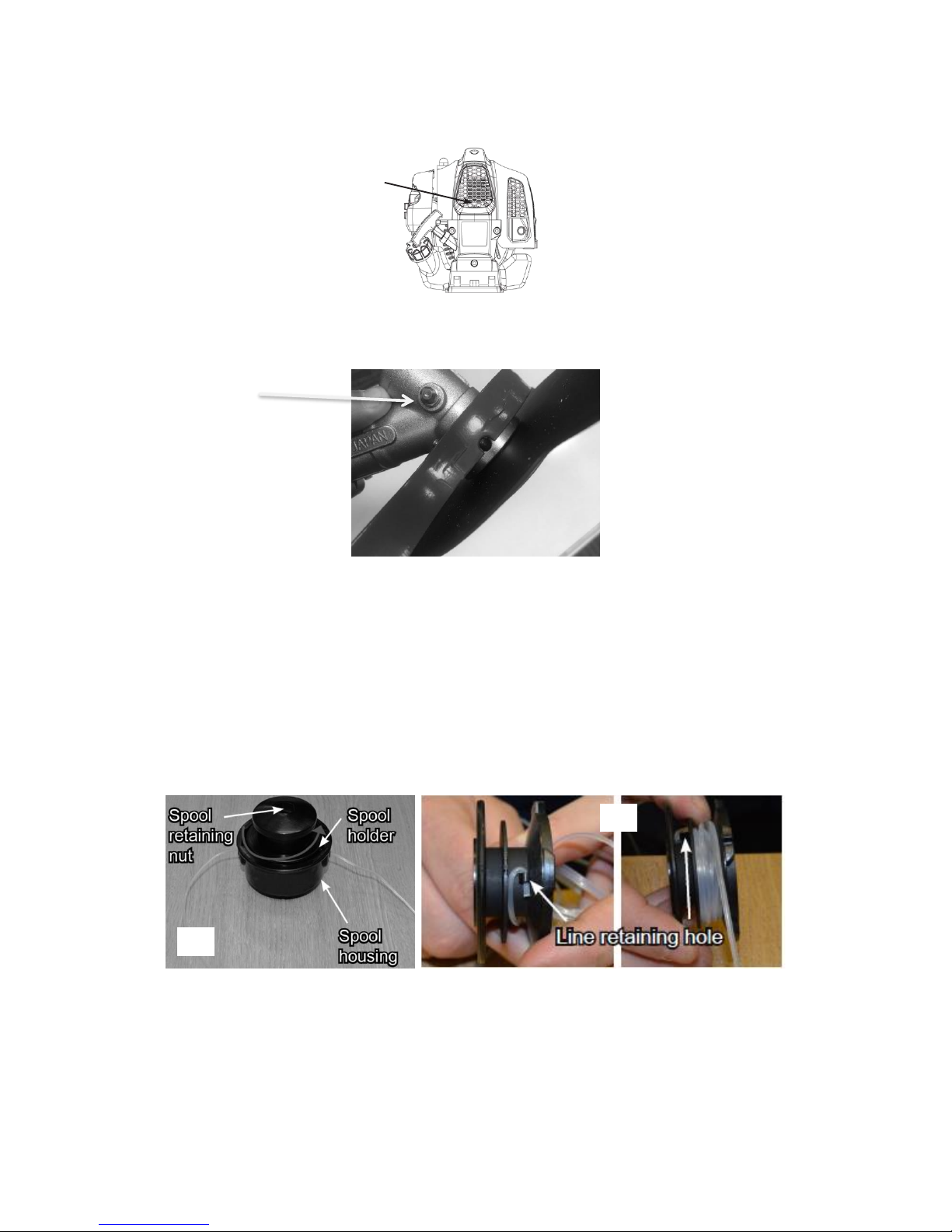

LINE TRIMMER

REFILLING THE TRIMMER LINE

1. Remove the spool retaining nut by turning it anti-clockwise. Take care not to lose the spring. Once the

spool retaining nut has been removed, take the spool holder from the spool housing.

2. Remove any old trimmer line. Locate the line retaining hole. Cut two equal 3m lengths of trimmer line

(2.4mm diameter) pieces. Take the end of one and thread approximately 4mm through the line retaining

hole. Now wrap the line around the retaining hole and around the spool holder, following the arrow on

the moulding.

3. Repeat the process and fill the other side of the spool. Ensure you wrap the trimmer line in the same

direction as the first side. This will allow the line to eject when using the bump feed system.

1.

2.

(1)

This manual suits for next models

1

Table of contents

Other The Handy Power Tools manuals