3

1.Introduction:

We congratulate you on the excellent choice! We wish you many pleasant moments with your new

pellet stove.

Do not leave the instructions unread. The installation and exploitation of the pellet stove should be made

in accordance with different legal obligations, which are explained in this instruction. According to the laws and

regulations for safety, when using an appliance of such class, the buyer and the user are obliged, with the help of

this instruction, to inform themselves for the assembling and the right operation of the appliance.

The manufacturer cannot be held liable for any damage caused as a result of incorrect installation,

incorrect maintenance procedures and improper use.

Your pellet stove is manufactured and tested in accordance with the requirements of the following

standards: EN 14785 EN 60335-1, EN 60335-1-102, EN 55014-1, EN 61000-6-1, EN 61000-6-3 and it is in accordance

with the approved technical documentation.

The appliance is not designed to be used by children and persons with limited physical, sensuous and

mental abilities, or by people with not enough experience and knowledge, except in cases when they are

watched and instructed how to work with this type of heater, by someone who is responsible for their own

safety

The pellet stove can be used and maintained only by adults who are familiar with the instruction manual.

2.Safety information:

The pellet stove must never be made to operate without water in the system or at a pressure less than 1

BAR. The stove can be damaged if it is ignited or used with no water in the system.

The stove is designed to heat water by means of automatic combustion of pellets (wood with 6 mm

diameter) in the combustion chamber

If not allowed fuels are used the warranty will void.

Please pay attention during the operation of the appliance children to be kept away from it, because stove

surface is too hot. Incineration danger!

The hazard which can come from not following the instruction manual: direct contact with electrical

(internal) parts, contact to the flame or with hot surfaces or when using un-allowed fuel.

If there is a malfunction in some part, the stove has safety devices which guarantee that it will automatically

shut down. The safety devices are activated automatically without any additional intervention.

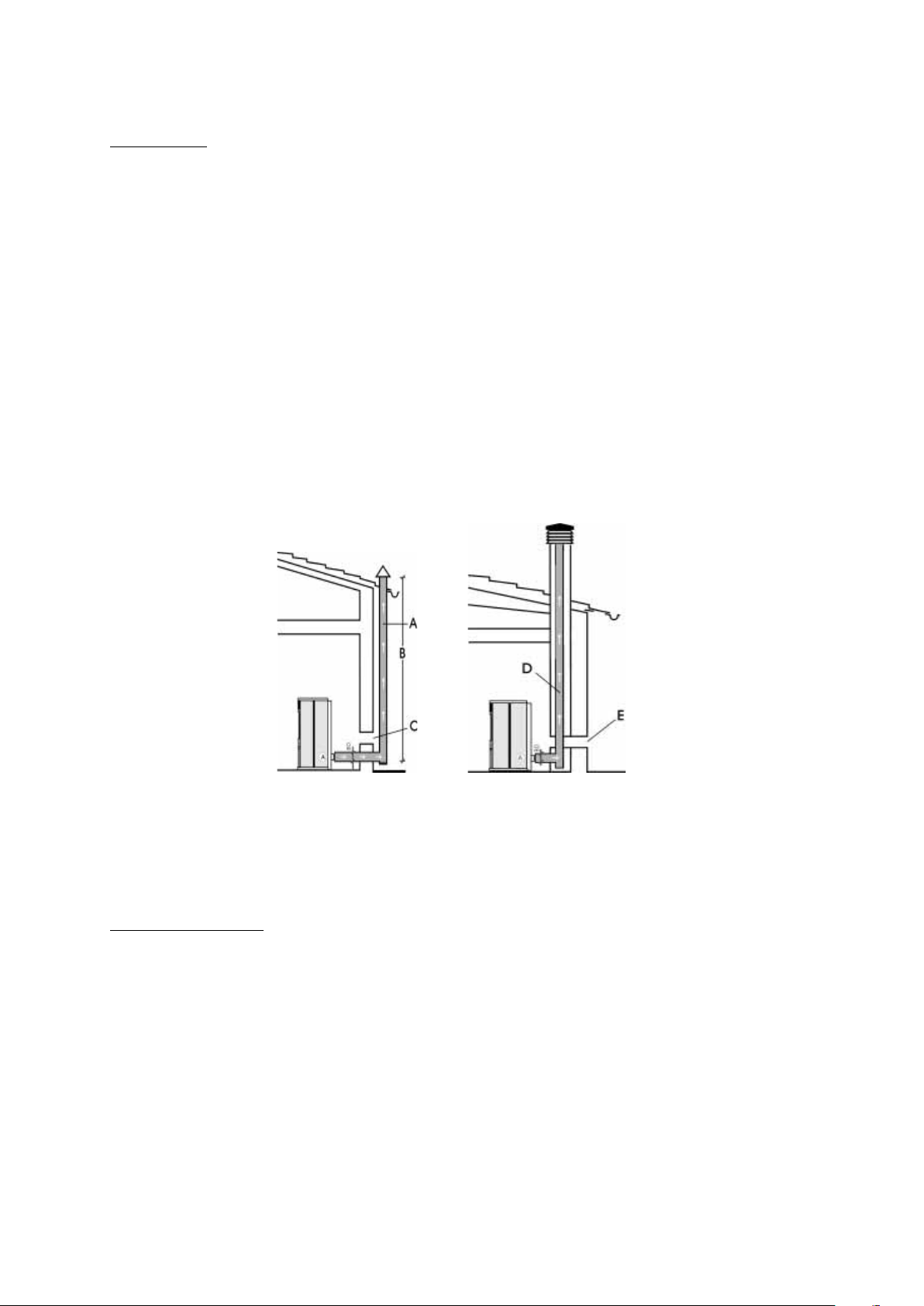

In order to function correctly, the stove must be installed in accordance with the instructions given here.

Whilst functioning, the door must never be opened. The combustion is fully automatic and requires no

manual intervention

It is absolutely forbidden to use the stove if the glass is damaged or broken.

The handle of the fire door is becoming as hot as the front part of the stove. The heat resisting glove should

be used when using the handle.

Is is strictly forbidden that any foreign substances be put into the combustion chamber or in the hopper.

Do not use flammable materials when cleaning the flue outlets.

Before cleaning or maintaining switch of the stove from electrical supply.

Use a vacuum cleaner to clean the fire chamber and hopper only when the stove is cold.

Never use water to clean the inside parts of the stove.

The glass can be cleaned when cold with a suitable product and a cloth. Do not clean when hot.