8

It is not recommended to install a pellet stove in rooms where there is mounted another heater. If it does, it must be equipped

with a separate air duct.

Compatibility with other devices:

Pellet stove should not be installed in the same room in which there are absorbers and / or devices that reduce ventilation in the

room.

Checking electrical connections:

Pellet stove is equipped with a power cable to be connected to a voltage 230V / 50Hz. Changes exceeding by 10% the voltage

can damage the appliance. Electrical grid-circuit must comply with the provisions of the laws and requirements for grounding.

According to the requirements for electrical grid-circuit connection, pellet stove should be installed to ensure free access to the

plug and socket (230V / 50Hz). According to the safety requirements it is prohibited the room where the pellet stove is installed

to have electrical installation mounted on the floor. Lack of bonding / grounding can cause damage for which the manufacturer

is not responsible.

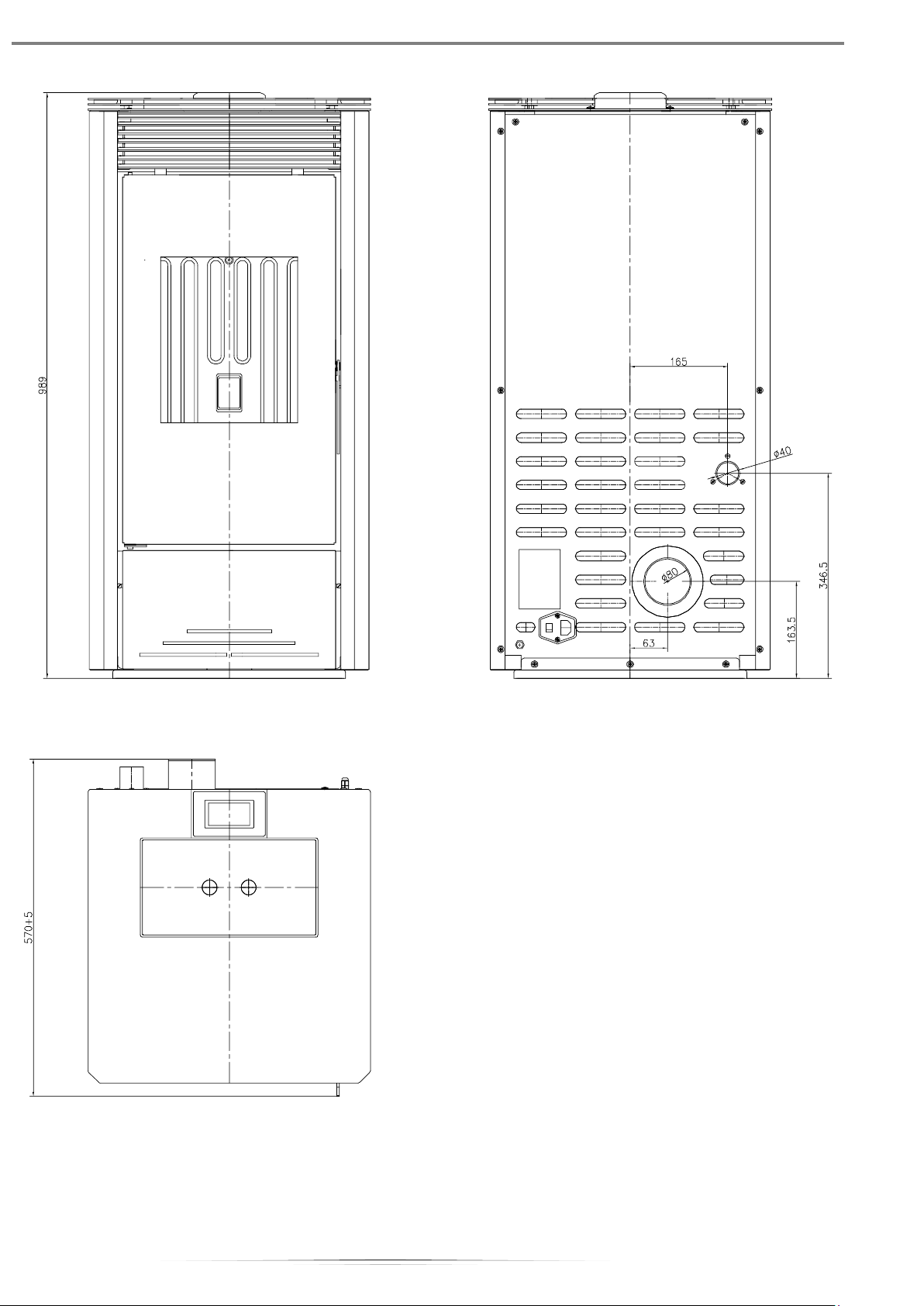

Positioning:

To ensure well operation, pellet stove should be levelled. The floor on which is placed the pellet stove must be of non-

combustible materials (concrete, marble, terracotta, etc.)

Given the easy servicing and refuelling, we recommend the following minimum free distance around the pellet stove: 1000 mm

at the front, back and sides -500 mm, top -minimum 1000 mm.

Safe distances for fire safety:

When installing a pellet stove and storage of wood pellets must be respected the fire requirements!

It is recommended that an appropriate place to mount a fire extinguisher be ensured.

It is forbidden to store the wood pellets directly to the pellet stove or less than a 400 mm.

The optimal distance between the pellet stove and combustible materials is 800 mm in front and 300 mm from the sides and the

back. Inflammable objects should not be placed on the top board of the pellet stove.

If the chimney is connected to the timber wall or other inflammable material, suitable materials such as ceramic wool should be

used to isolate it.

Fresh air opening:

Imperative to ensure submission of fresh air!

The room, in which is mounted pellet stove must have an opening for fresh air with a cross section of not less than 80 cm² to

ensure a sufficient supply of oxygen necessary for combustion. Additionally, it can be delivered outside air through a pipeline of

Ø 50 mm. In this case, it is possible to emerge condensate. If necessary, the opening for external air can be protected by a grid.

Pipe for outside air must be mounted on the nearest outer wall to the pellet stove. Its length should not exceed 1 m, should not

have curves and its location must prevent clogging. The outer end of the pipe must end with a knee 90˚, downward or be

provided with protection against wind.

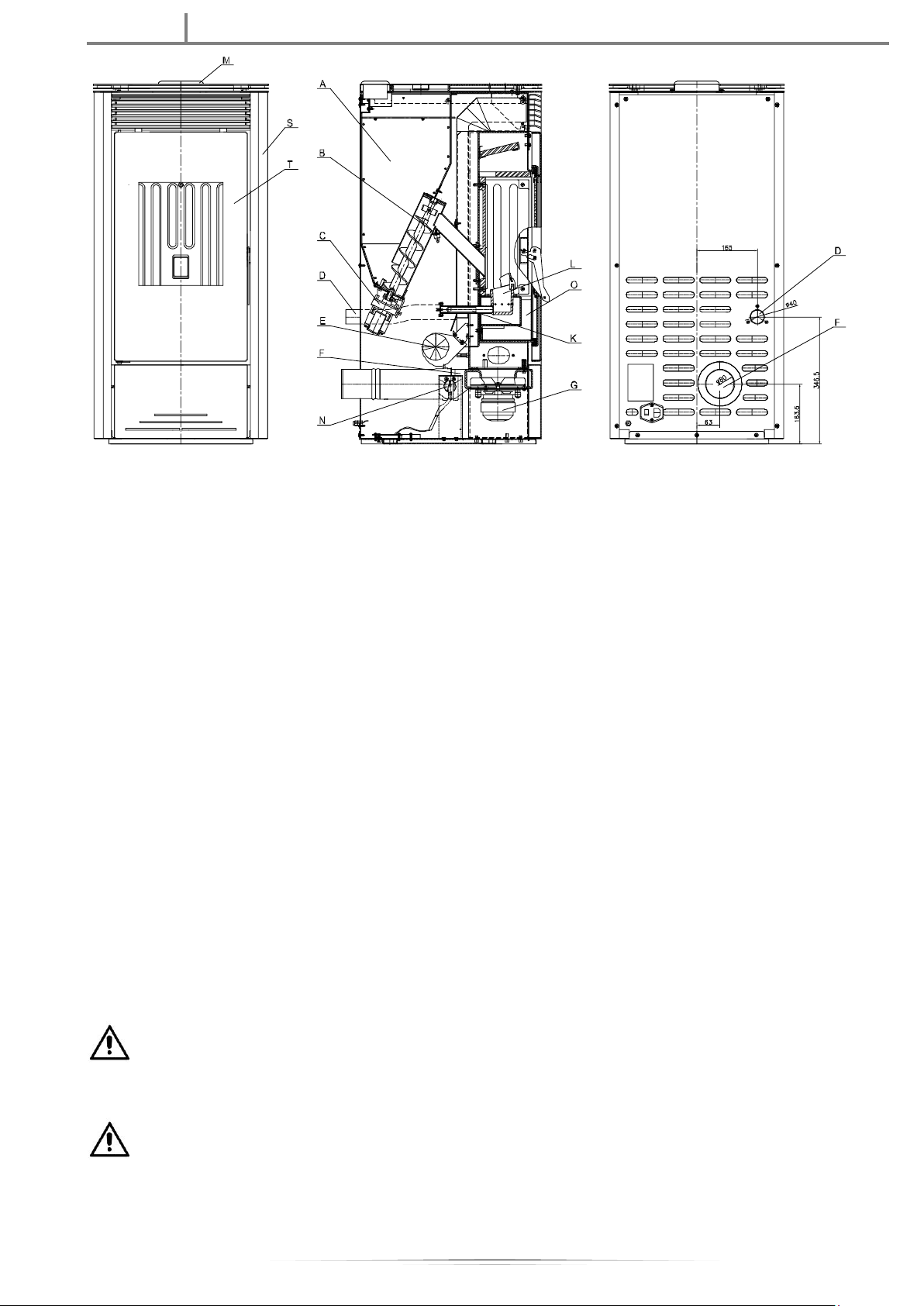

Chimneys:

Pellet stove works constantly with a fume extractor and pressure in the flue pipes and chimney.

It is forbidden flue gases to be discharged directly from the pellet stove through the wall into the atmosphere. Required installed

chimney, which takes flue gases safe for human health altitude over the area of habitation.

Only the pellet stove should use chimney and no other appliances must be connected to it. The flue gases are emitted from the

combustion chamber of the pellet stove to the atmosphere through a flue socket Ø 80 mm located in the rear. It is

recommended at the beginning of the vertical section of the chimney to mount a T-fitting, with a section for collecting

condensate. Pellet stove must be connected to the chimney by steel flue pipes, certified according to EN 1856. The flue pipe

system must be hermetically insulated with materials resistant to high temperatures (heat-resistant silicone or grease). Allowed

to have a horizontal section with a length of 2 m. Horizontal section must be a minimum slope of 3% and not more than two

curves at 90°.

If the flue socket of the pellet stove is connected to a metal chimney, it must have a vertical portion length of not less than 1.5 m

and fitted with a wind protection. Chimney may be located internally or externally. It should be well insulated.

If the pellet stove is connected to a masonry chimney, it must be intended for appliances for solid fuel. If the chimney has a size

larger from Ø150 mm in diameter, internally along its entire length must be installed tube of stainless steel with a diameter of

Ø150 mm, as the free space must be isolated by masonry. All parts of the chimney should have free access to inspection. At the

bottom of the chimney must be built manhole allowing opening and cleaning at least once a year. On top of the chimney must

be installed a wind protection hat, according to current regulations.