3

1. Introduction.

We congratulate you on the excellent choice!

Do not leave this instruction manual unread. Installation and operation of a pellet stove associated with various legal

obligations, which are explained in this instruction manual. According to the laws and regulations for safe use of

appliances of this class, the purchaser and user of the pellet stove undertake using this instruction manual to inform

themselves for the assembling and the right operation of the appliance.

This instruction manual is provided to assist you and the team that will install, put into operation and service pellet stove.

Technicians, who will carry out the above activities to the pellet stove, must be trained and competent.

Pellet stove operated only by adult persons familiar with the instruction manual. Pellet stove is not intended for use by persons

with limited physical, sensory or mental abilities or lack of experience and knowledge, unless they are instructed and supervised

in the use of the appliance by a person responsible for their safety.

Pellet stove is manufactured and tested in accordance with standards EN 14785, EN 60335-1, EN 60335-1-102, EN 55014-1, EN

61000-6-1, EN 61000-6-3 and meets the approved technical documentation.

Failure to follow the instructions described in this manual can lead to damage and consequences for which the manufacturer is

not responsible.

2. Safety Information.

•Pellet stove must not run without water in the system and the pressure must not fall below 1 bar. Should the system be

alighted without water, pellet stove can be damaged.

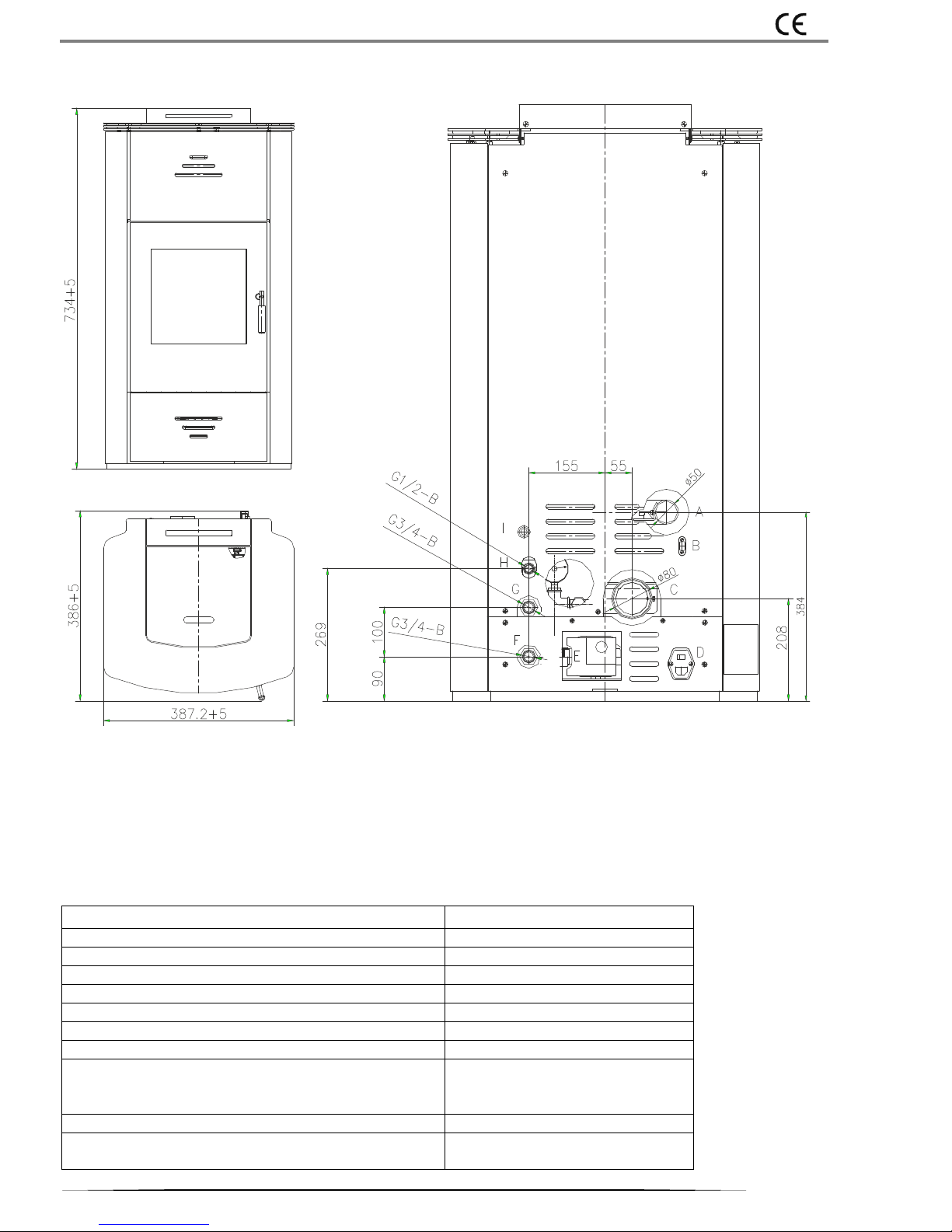

•Pellet stove is designed to heat water through automated burn in the combustion chamber of wood pellets with a

diameter of Ø 6 mm.

•Warranty is voided by unauthorized use of combustible material.

•The risk that could arise from non-compliance of this instructions manual is a direct contact with electric parts (internal),

contact with fire or hot surfaces.

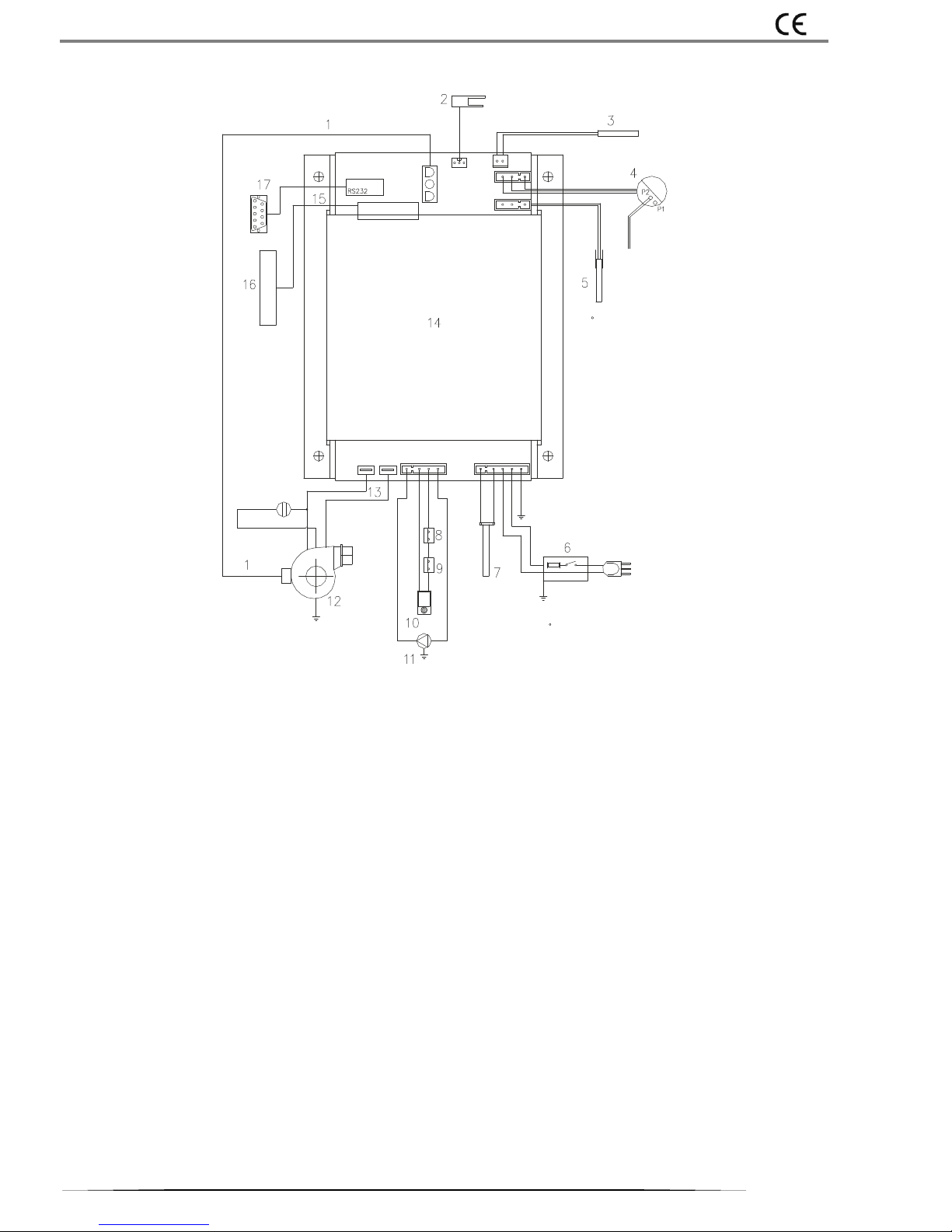

•Pellet stove is equipped with safety components that guarantee lock it automatically in case of failure of any of its

components. Safety components are activated without outside interference.

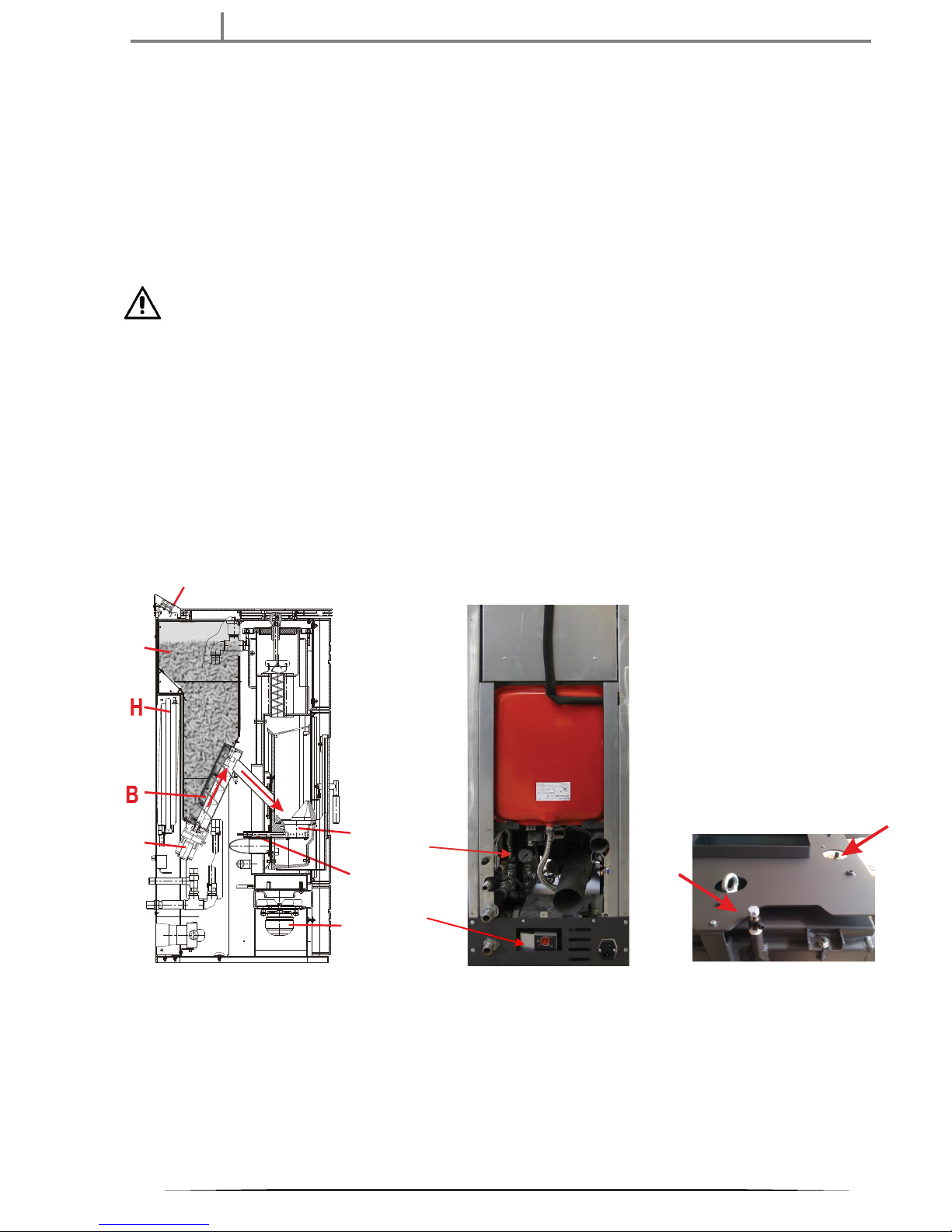

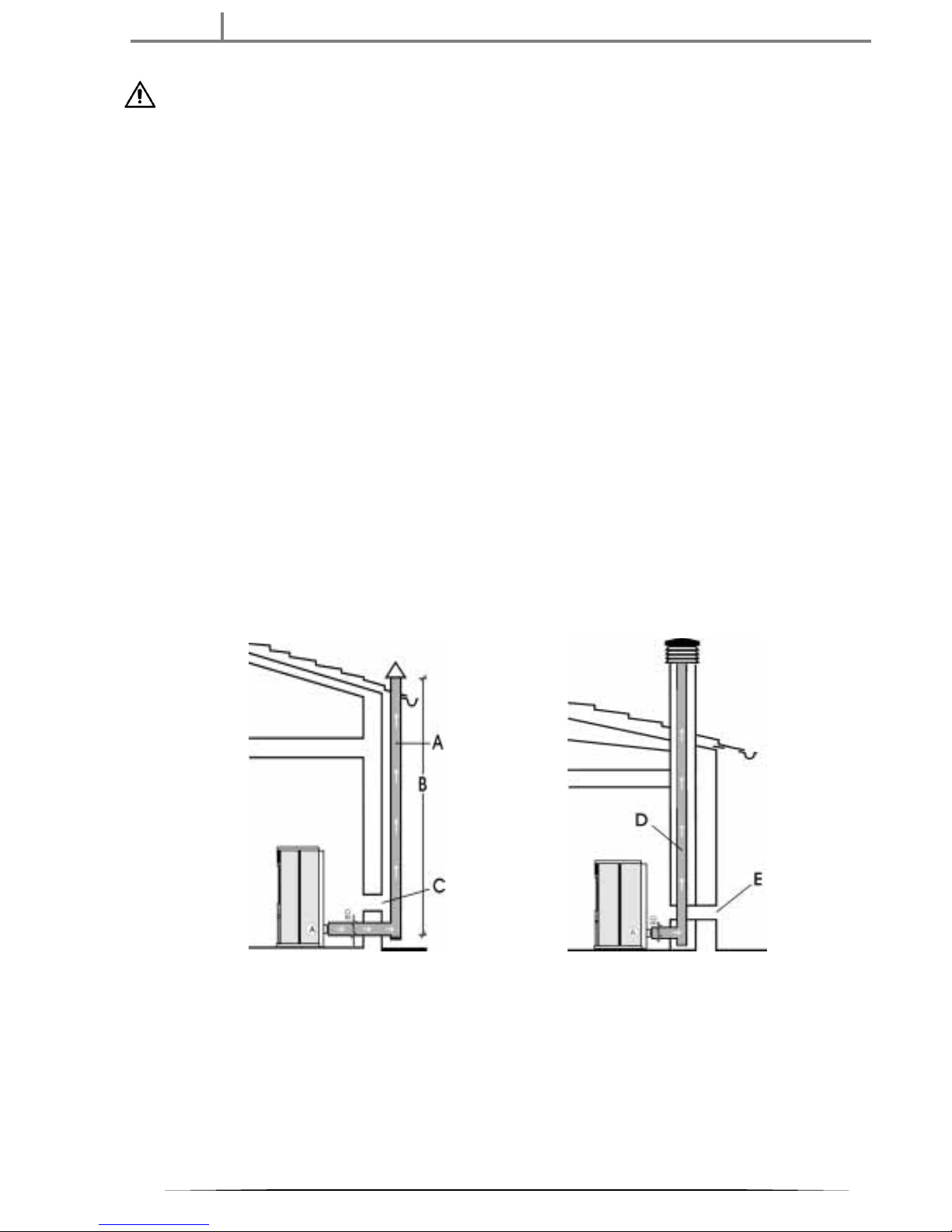

•Necessary for the proper operating of the pellet stove is its proper installation in accordance with the following

instructions.

•Fire door should not be opened during operation of the pellet stove. The burning process is automated and does not

require external intervention.

•Do not allow to burn the pellet stove if there are cracks in the glass.

•Under no circumstances should not be allowed penetration of foreign substances in the firebox or hopper.

•Do not use combustible materials to clean soot in the chimney.

•Turn off the pellet stove from the grid-circuit before cleaning or servicing.

•Use a vacuum cleaner to clean the combustion chamber and pellet fuel hopper only when pellet stove is cold.

•Do not use water to clean the internal parts of the pellet stove.

•ATTENTION! During operation of the pellet stove must not be allowed to touch a child to its surface as it is hot. Danger

of burns!

•The handle of the pellet stove warms as much as the front panel, so it must be operated with a heat-resistant glove.

During operation of the pellet stove flue pipes and fire door are hot.

•Do not place flammable objects and liquids away from the pellet stove.

•NEVER use flammable liquids to burn the pellet stove.

•Do not obstruct fresh air to enter the room where pellet stove is installed and through the holes on the pellet stove.

•Do not soak pellet stove and do not touch electrical components with wet hands.

•Do not mount any adapters to flue pipes and chimney.

•To operate properly and safely, pellet stove should be installed in a room that is fire-resistant and equipped with

everything needed (electricity, air exchange, vents).

•The temperature of the room where it is installed the pellet stove must not be lower than 0˚C.

•Use appropriate non-freezing additives for water in the system.

•Make sure the temperature of the return water is not lower than 45˚C.

•Rating label is placed on the back of the pellet stove.

•Keep this instruction manual, warranty card and purchase invoice in good condition, as will be necessary in any inquiries.

In extinction, doth not burn a pellet stove again before cleaning the combustion chamber!

Removed pellets from the combustion chamber should not be placed back in the pellet fuel hopper!