3

1.4 VE.Direct BlueSolar and SmartSolar MPPT Chargers compatibility

For proper operation, the system needs to be able to control the charge current either

through REVOV battery parameters or through DVCC control within the system. Therefor it is

recommended to use Victron 48V compatible MPPTs models with VE. Direct port or VE. Can

for charging.

1.5 MPPTs with a VE. Direct port

MPPTs are controlled via the GX device. Make sure the GX device runs the latest rmware

version, and the MPPTs run the latest available version. Once this has be done in an initial

system conguration, disable the auto-update feature on all devices

The MPPT requires connection to the GX device to regulate charge currents based on

system parameters as the batteries require (due to temperature, etc). To test operation, try

disconnecting the GX device from the MPPT. After a time-out, the MPPT will stop charging

and ash an error code on its LEDs. The error code is error #67: no BMS.

1.6 MPPTs with a VE. Can port

New Model (2019 and later) VE. Can MPPTs are also supported from rmware version 1.06 and

above. Be aware that some GX devices (e.g. CCGX) only have a single CAN Bus interface,

and that is required for the battery communications. So if you use a new VE. Can MPPT, it

must also be with a GX device that has more than one CAN bus interface, e.g. the Cerbo GX

Old model VE. Can MPPTs (pre 2019) are not supported.

2. Minimum Warranted Battery Sizing Recommendations

Once DVCC (Please read Victron DVCC document) is enabled on the GX device, the

charge and discharge rates are managed by the REVOV battery. It is critical that correct

system sixing steps have been followed for these features to operate accordingly.

Using very large solar arrays with battery banks that are too small can exceed the limits of

the batteries ability to charge and possibly lead to the BMS triggering over-current alarms or

permanent damage to the system.

You must have the minimum number of battery modules to supply the inverters start-up inrush

surge current which charges the capacitors when the inverter is rst connected, this occurs

prior to any loads being connected. There is also the subsequent potential current demand

of the load/s connected to the inverter. It is much more desirable to have the inverter/

charger overload than the battery, as the inverter will automatically recover, whereas the

battery or system may require intervention once in a fault state.

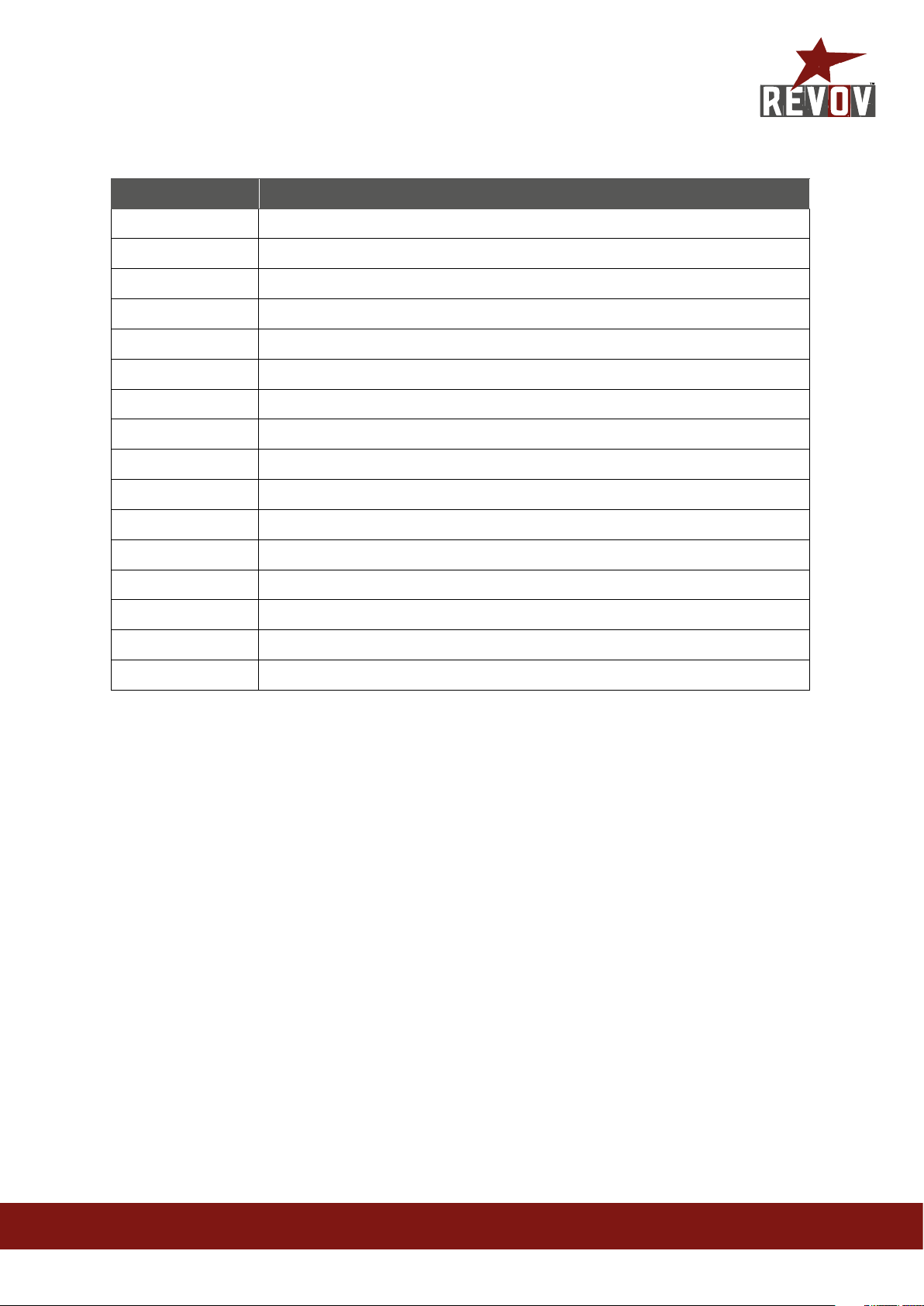

Minimum suggested battery sizing’s for common Victron inverter/chargers are listed below.

These are suggestions for reliable operation for single or three phase operation, on and o

grid and serve as a minimum warranted sizing by REVOV.

Using the below formula, an example of minimum system sizing based on the R100 battery

module. Each battery module is approximately 100Ah at 51.2V, can provide 80A continuous

discharge/charge and 100A peak for several minutes.