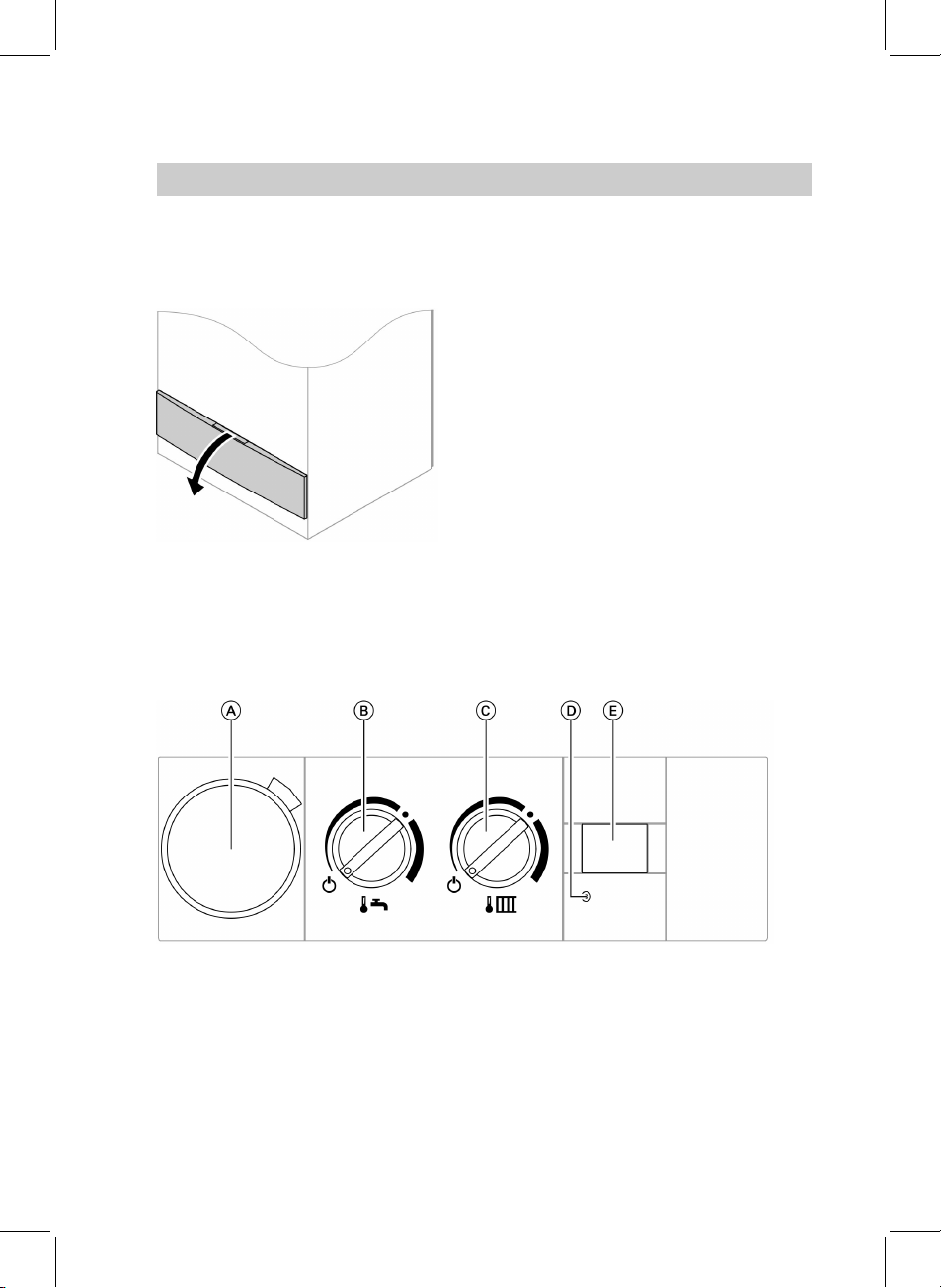

Your Vitodens can be operated in the "Heating" or "DHW" operating modes.

Heating mode

If a Vitotrol 100 room temperature

controller is connected, it is used to

set the required room temperature.

Please refer to the separate operating

instructions.

If the setting on the room temperature

control unit is inadequate for achiev-

ing the required room temperature (e.

g. during an extremely cold winter),

the heating water temperature can

also be modified using the rotary

selector tr.

DHW heating - combi boiler

In the event of a demand for hot

water, the appliance will detect water

flow and initiate the ignition

sequence. The fan (and pump) will

start and the boiler will light.

If the hot water demand is near to the

maximum design flow rate the boiler

will run continuously at full output until

the tap is closed or the flow rate is

reduced, the heat input will be

reducedtomaintainasteadypre-set

temperature at the tap.

Hot water is available almost instanta-

neously from the boiler, but the final

outlet temperature and the delay in

reaching full temperature will depend

ontheflowrateandthedistancefrom

the boiler to the tap.

When the tap is closed the boiler will

return to heating mode, if there is a

demand for heating, otherwise the

boiler will shut down until the next

demand for heating or hot water.

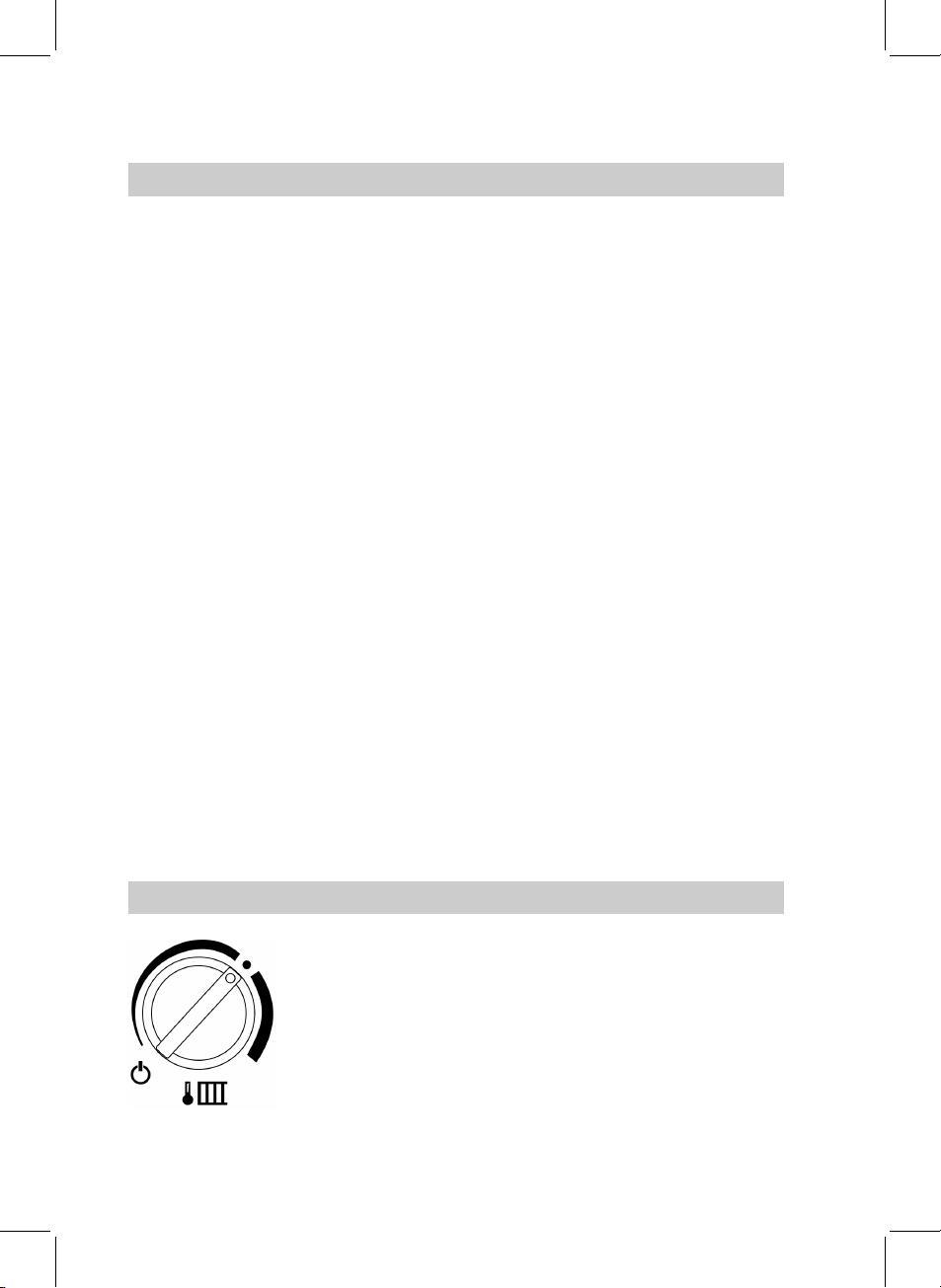

Heating

Switching ON:

Move rotary selector tr to the

required heating water temperature.

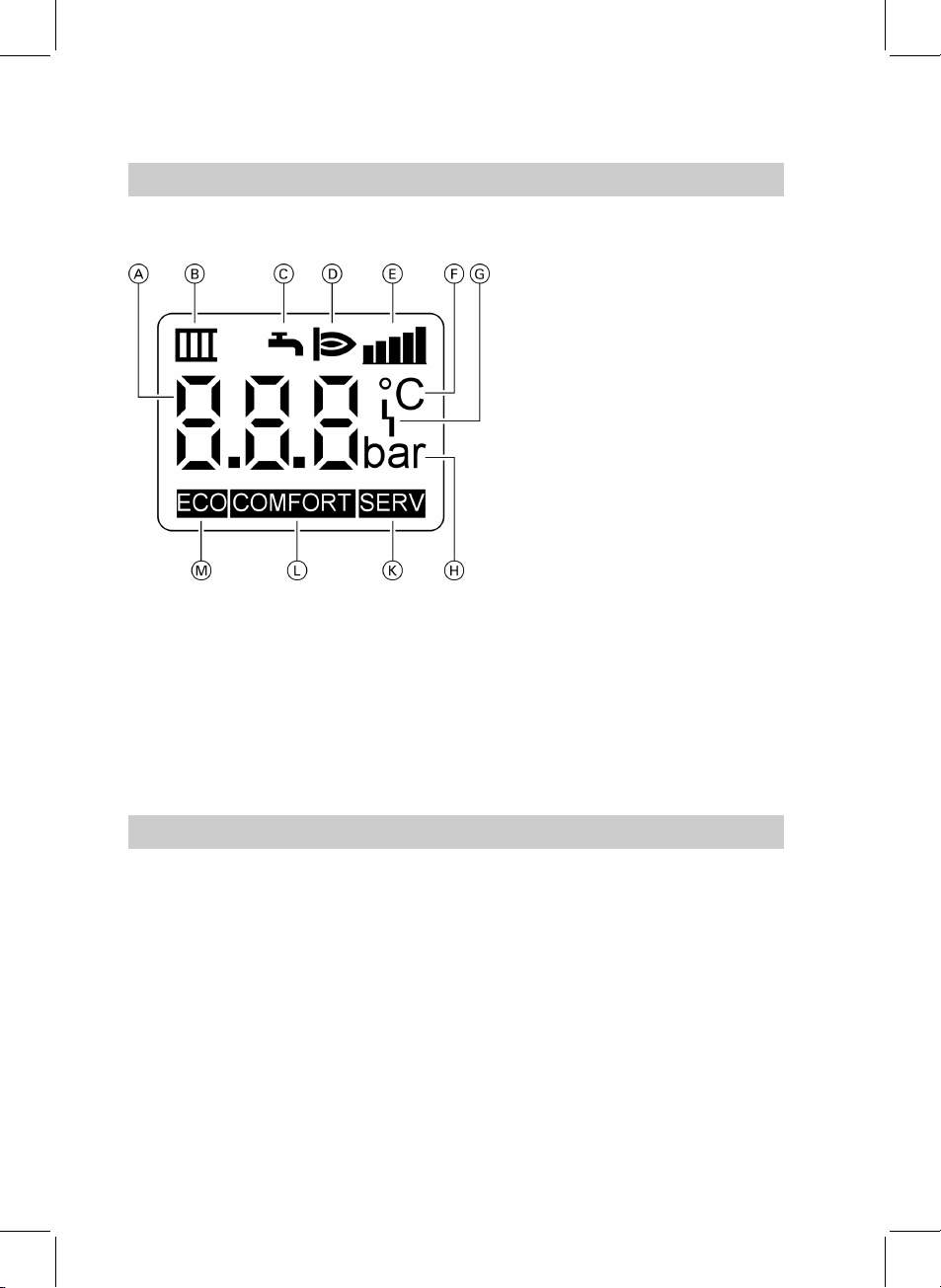

If central heating is active, the indica-

tor rappears on the display.

Switching OFF:

Turn rotary selector rt to 9.

Operating modes

10

Settings

5592 521 GB