Viessmann VITOCROSSAL 300 Operating instructions

Other Viessmann Boiler manuals

Viessmann

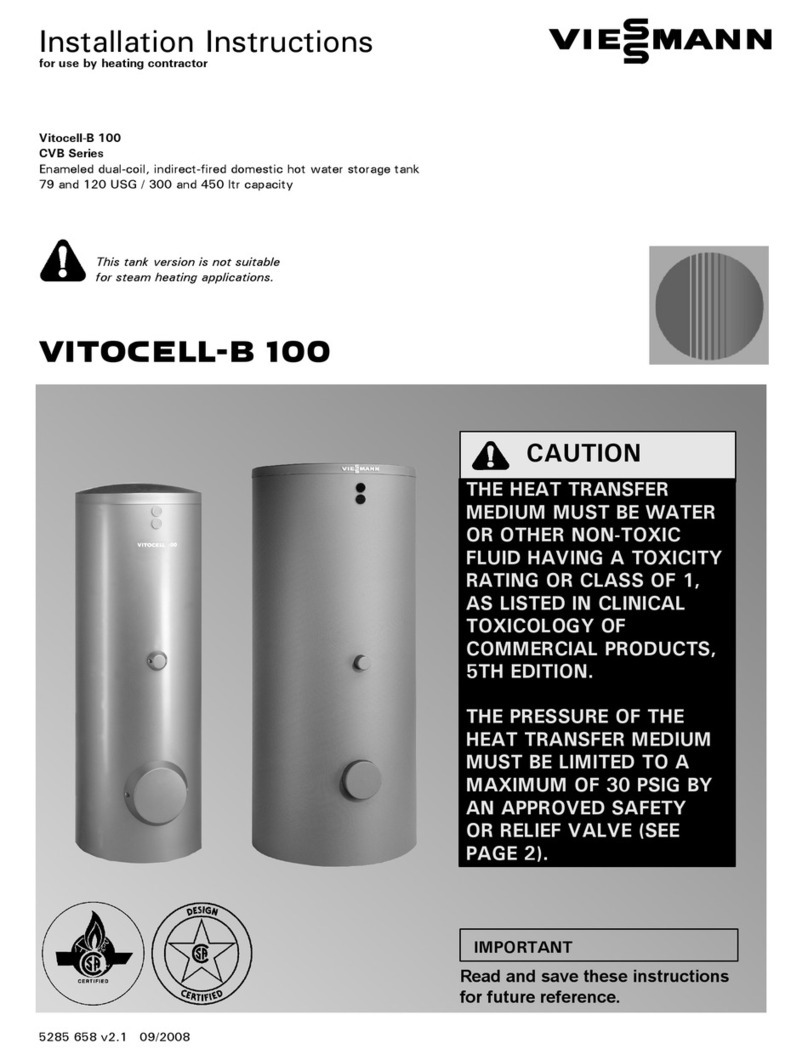

Viessmann Vitocell-B 100 CVB Series User manual

Viessmann

Viessmann Vitocrossal 300 CT3 SERIES Quick start guide

Viessmann

Viessmann VITODENS 050-W Quick guide

Viessmann

Viessmann Vitodens 111-W Quick start guide

Viessmann

Viessmann Vitodens 200-W System Operating instructions

Viessmann

Viessmann VITOROND 200 Original operating manual

Viessmann

Viessmann VITOLADENS 300-W Operating instructions

Viessmann

Viessmann Vitoladens 300-C User manual

Viessmann

Viessmann Vitodens 050-W BP JD Quick guide

Viessmann

Viessmann VITORADIAL 300-T User manual

Viessmann

Viessmann Vitodens 100 Quick guide

Viessmann

Viessmann VR2 Series User manual

Viessmann

Viessmann Vitodens 200-W System Operating instructions

Viessmann

Viessmann Vitodens 200 WB2 11-44 User manual

Viessmann

Viessmann VITOCROSSAL 300 User manual

Viessmann

Viessmann VITODENS 200 Quick start guide

Viessmann

Viessmann VITOCELL 100-V User manual

Viessmann

Viessmann VITOROND 200 Instruction manual

Viessmann

Viessmann KOB PYROT KRT SERIES Instruction manual

Viessmann

Viessmann VITOLADENS 300-W Quick guide

Popular Boiler manuals by other brands

Ferroli

Ferroli DOMIcompact F 30 D null

Vaillant

Vaillant uniSTOR VIH SW GB 500 BES operating instructions

Radijator

Radijator BIO max 23.1 instruction manual

Brunner

Brunner BSV 20 Instructions for use

Buderus

Buderus Logamax GB062-24 KDE H V2 Service manual

Potterton

Potterton 50e Installation and Servicing Manual

UTICA BOILERS

UTICA BOILERS TriFire Assembly instructions

Joannes

Joannes LADY Series Installation and maintenance manual

ECR International

ECR International UB90-125 Installation, operation & maintenance manual

Froling

Froling P4 Pellet 8 - 105 installation instructions

Froling

Froling FHG Turbo 3000 operating instructions

U.S. Boiler Company

U.S. Boiler Company K2 operating instructions