4. 9 Pipes: Tee, bends, reducers ....................................................................................... 29

■ Tee .......................................................................................................................... 29

■ Tee with reducer ..................................................................................................... 29

■ Bend 90° ................................................................................................................. 30

■ Bend 45° ................................................................................................................. 30

■ Reducer 160/125 .................................................................................................... 30

■ Reducer 125/100 .................................................................................................... 30

■ Reducer 180/160 .................................................................................................... 30

5. Installation accessories for venti-

lation air/extract air, plastic duct

system

5. 1 Ventilation air apertures .............................................................................................. 31

■ Ventilation air valve DN 125 with diverter for wall and ceiling installation ............... 31

■ Floor outlet with grate ............................................................................................. 31

5. 2 Extract air apertures ................................................................................................... 32

■ Extract air valve DN 125 with diverter ..................................................................... 32

5. 3 Air distribution boxes .................................................................................................. 32

■ Restrictor ................................................................................................................. 33

5. 4 Flat duct, system 100 .................................................................................................. 34

■ Flat duct .................................................................................................................. 34

■ Connection piece .................................................................................................... 34

5. 5 Flat duct: Bends .......................................................................................................... 34

■ Bend 90°, broad side .............................................................................................. 34

■ Bend 90°, narrow side ............................................................................................. 34

5. 6 Lip seal ....................................................................................................................... 35

■ Part no: 7440 213 ................................................................................................... 35

5. 7 Locking cap ................................................................................................................. 35

■ Part no: 7440 217 ................................................................................................... 35

6. Design information 6. 1 Positioning .................................................................................................................. 35

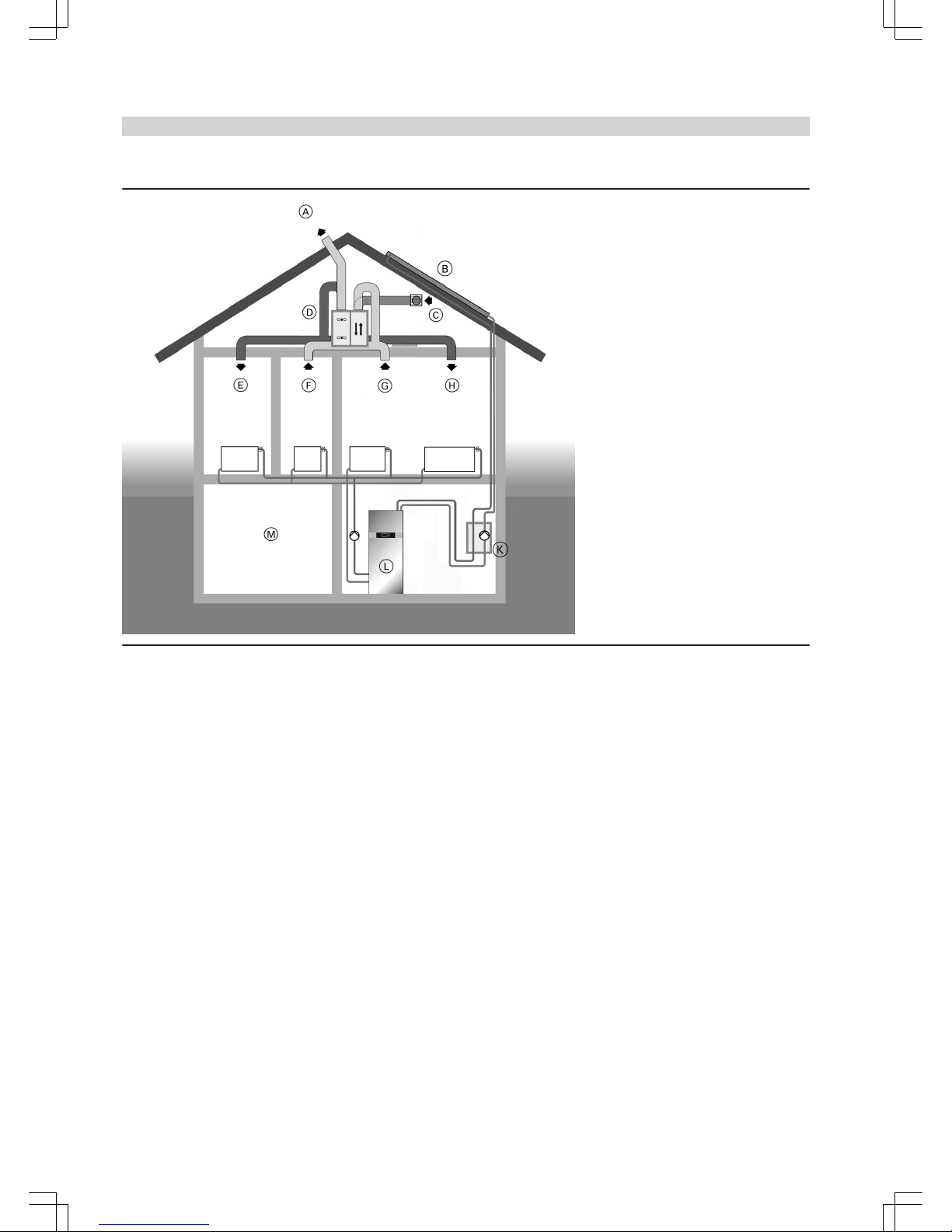

■ Application .............................................................................................................. 35

■ Fire protection ......................................................................................................... 35

■ Airtight building ....................................................................................................... 35

■ Installation room requirements ................................................................................ 35

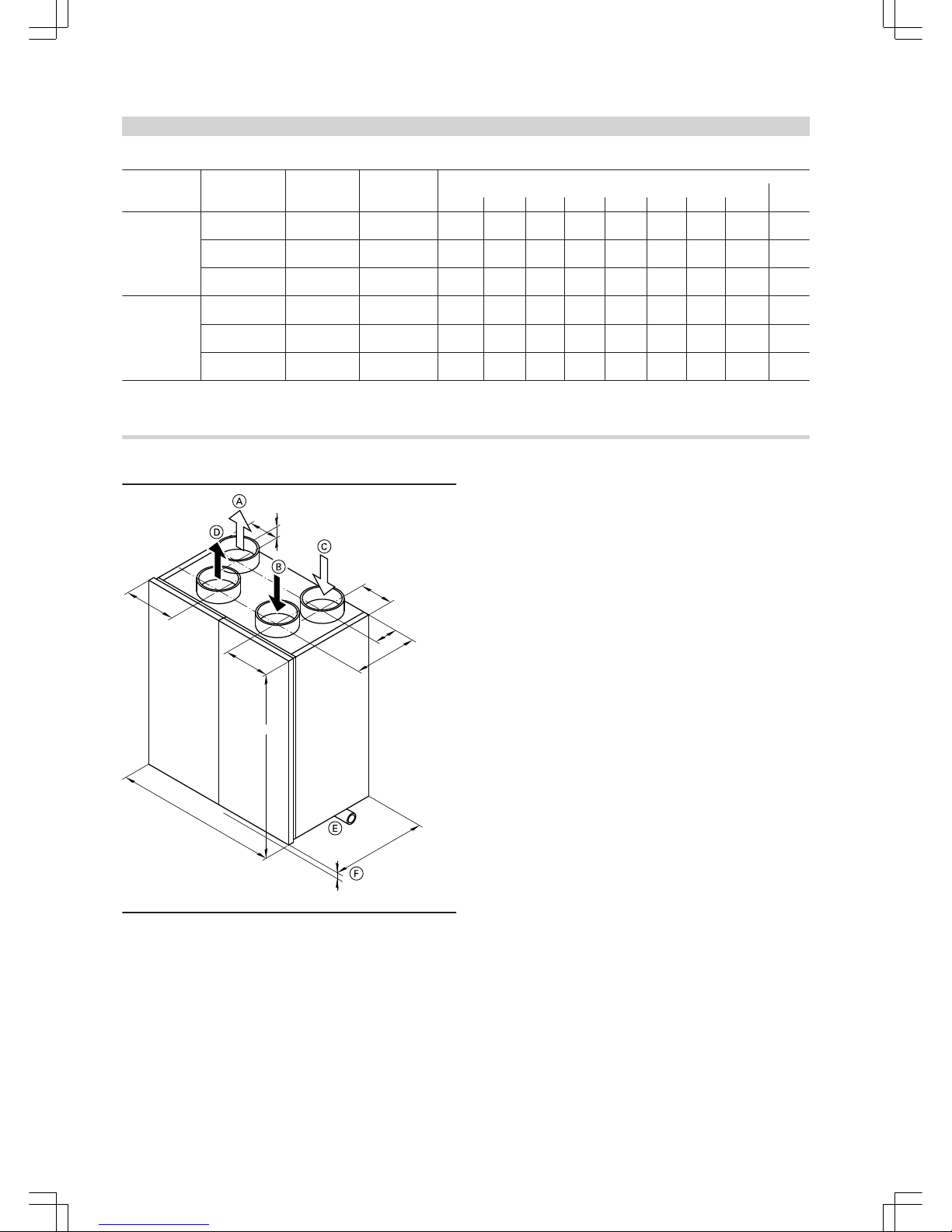

■ Installation options .................................................................................................. 36

■ Open flue combustion equipment and ventilation equipment ................................. 38

■ Extractor hoods, tumble dryers and Vitovent .......................................................... 38

6. 2 Electrical connection ................................................................................................... 38

6. 3 Condensate drain ....................................................................................................... 38

6. 4 Operating mode .......................................................................................................... 39

■ Air flow rate ............................................................................................................. 39

■ Operation with heat recovery .................................................................................. 40

■ Operation without heat recovery (e.g. in summer) .................................................. 41

■ Ice guard ................................................................................................................. 41

6. 5 Duct system ................................................................................................................ 43

■ Example of routing ducts behind suspended ceilings ............................................. 43

■ Outside air supply and expelled air aperture .......................................................... 43

■ Ventilation air and extract air duct ........................................................................... 44

■ Flat duct system ...................................................................................................... 45

■ Sound insulation and silencer ................................................................................. 46

■ Thermal insulation for the duct system ................................................................... 46

7. Sizing 7. 1 Overview of engineering procedure ............................................................................ 46

7. 2 Separating the rooms into those to be ventilated and those from which air should be

extracted ..................................................................................................................... 47

■Example: Detached house, total available area 138.9 m2 ...................................... 48

7. 3 Calculating the air flow rates ....................................................................................... 49

■ Calculating air flow rates for the example on page 48 ............................................ 49

7. 4 Selecting the Vitovent ................................................................................................. 50

7. 5 Determining the number of ventilation and extract air apertures per room ................. 50

7. 6 Determining the installation location of the Vitovent and the duct system .................. 51

■ Installation location of the Vitovent and the duct system for example on

page 48 ................................................................................................................... 51

7. 7 Identifying part sections, ventilation and extract air apertures .................................... 52

■ Identifying part sections, ventilation and extract air apertures for example on page

48 ........................................................................................................................... 53

7. 8 Calculating the external pressure drop ....................................................................... 54

■ Calculation of the external pressure drop for a metal duct system for example on

page 48 ................................................................................................................... 54

7. 9 Calculating the external pressure drop for a plastic duct system ............................... 55

7.10 Overview of components ............................................................................................ 56

■ System illustration, metal duct system .................................................................... 56

■ System illustration, plastic duct system .................................................................. 59

Index (cont.)

VITOVENT 300 VIESMANN 3

5724 798 GB