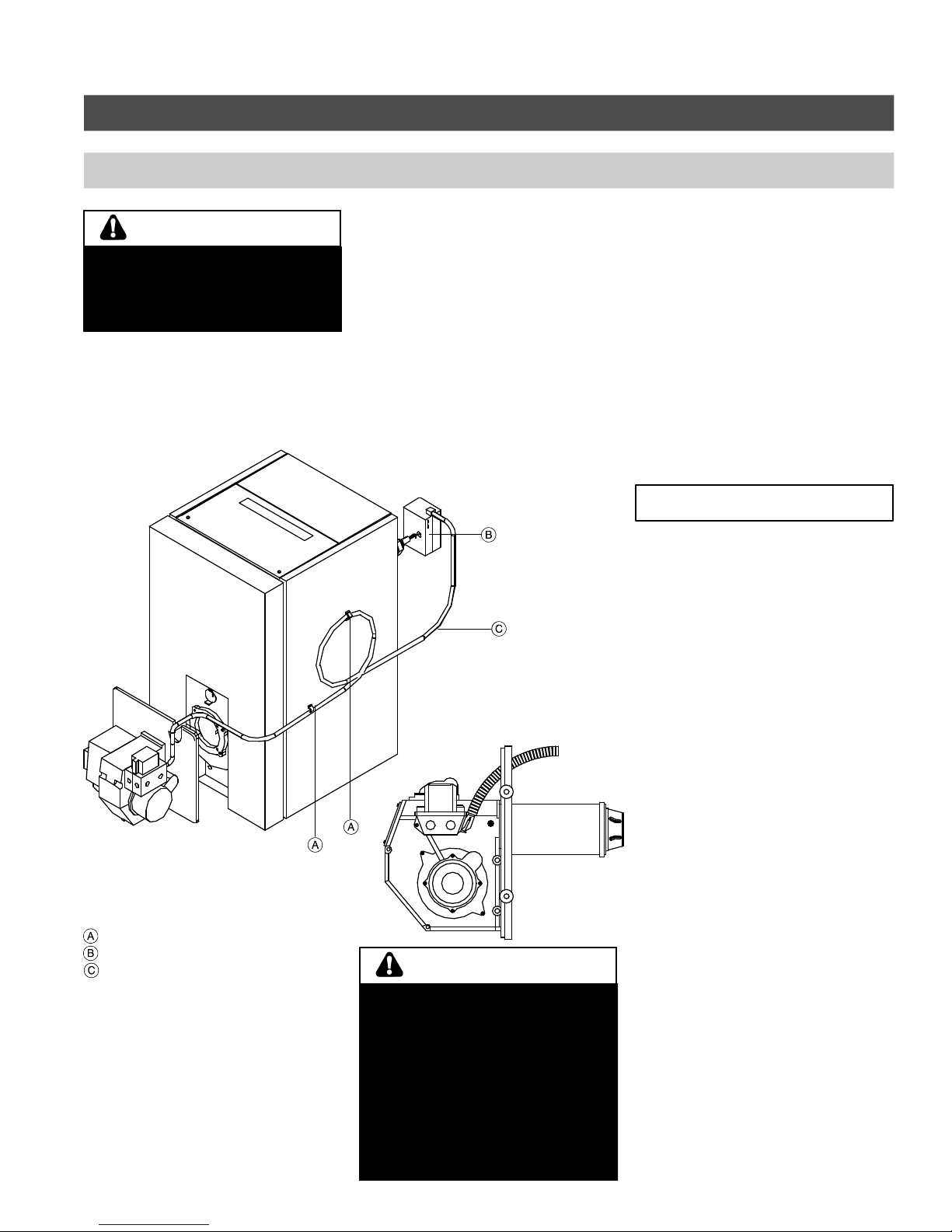

Burner - Beckett

Fig. 2

3

Burner Set-up (Beckett)

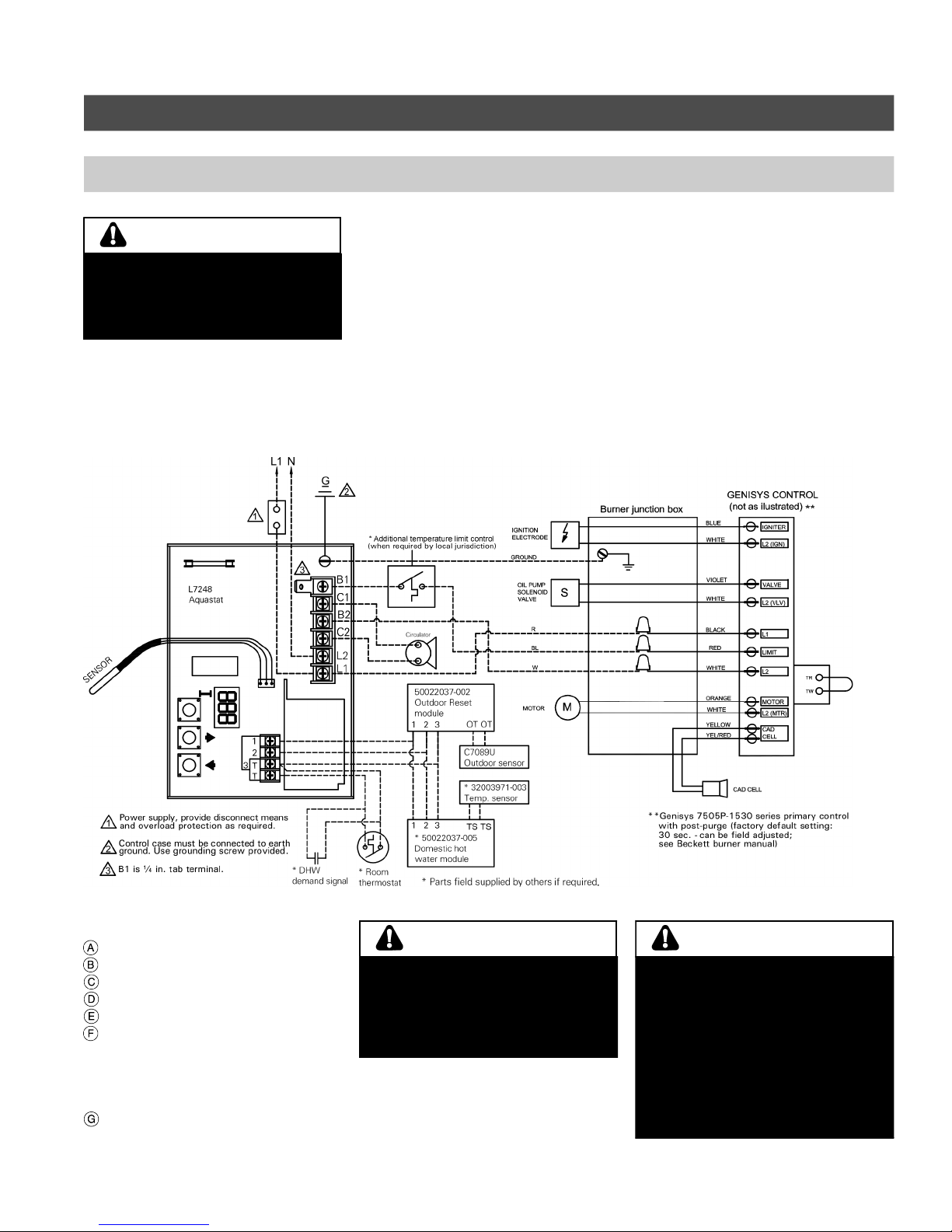

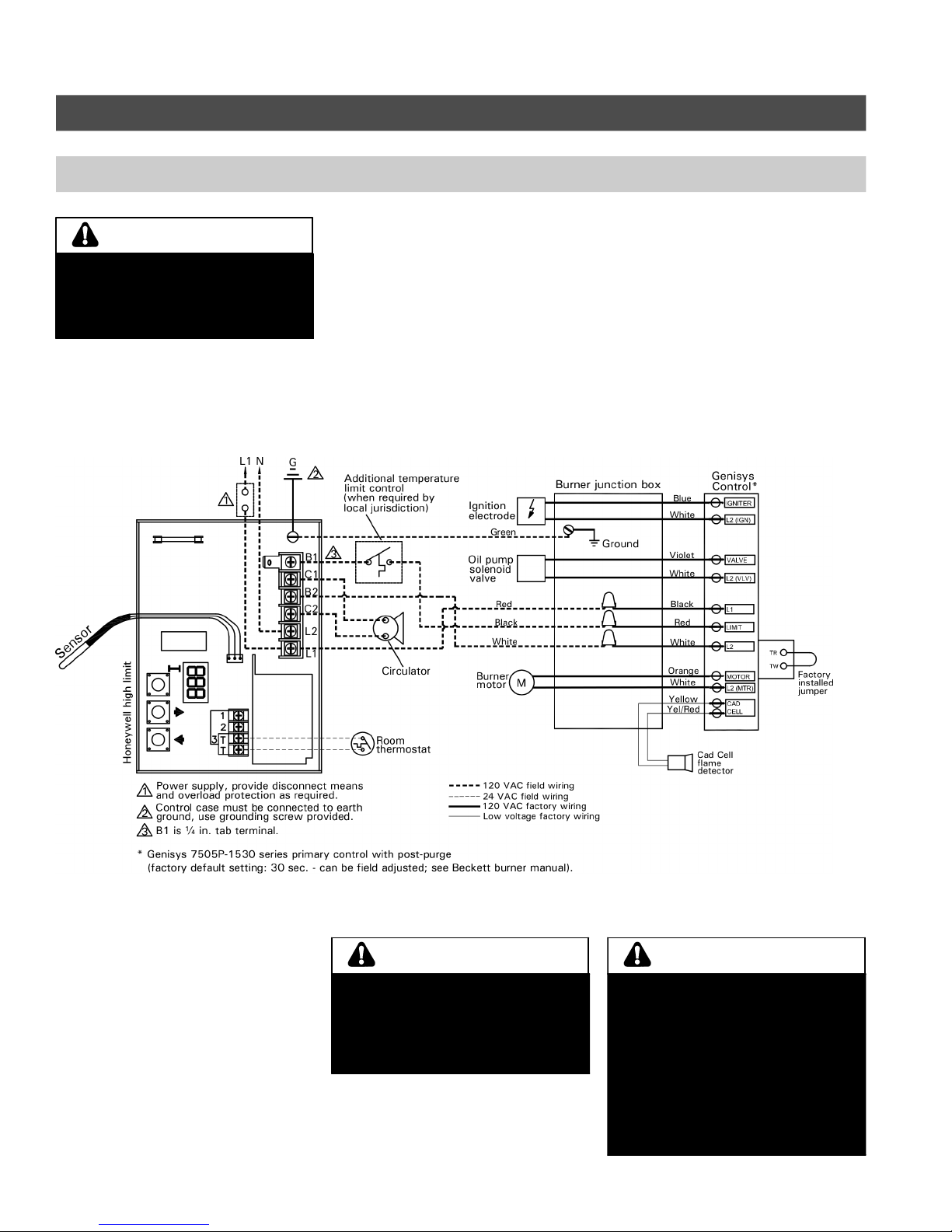

Electrical connections (with Aquastat control)

Installations must follow these codes

and requirements:

- National Electrical Code, ANSI/NFPA

70, latest edition and any addtional

national, state or local codes.

- In Canada, CSA C22.1 Canadian

Electrical Code Part 1 and any local

codes.

- Wirin must be N.E.C. Class 1. If

ori inal wire as supplied with boiler

must be replaced, type 105°C wire

or equivalent must be used. Supply

wirin to boiler and additional control

wirin must be 14 a. or heavier.

- Provide electrical round at boiler as

required by codes.

"

All field supplied nominal 120 VAC voltage wiring must be sheathed in a flexible metal conduit.

"

Disconnect means, overload protection and low water cut-off must be provided as required by local codes.

"

Connect incoming line voltage HOT (L1) wire to terminal L1, and N to terminal L2 of the Honeywell high limit control (see

wiring diagram on page 5.

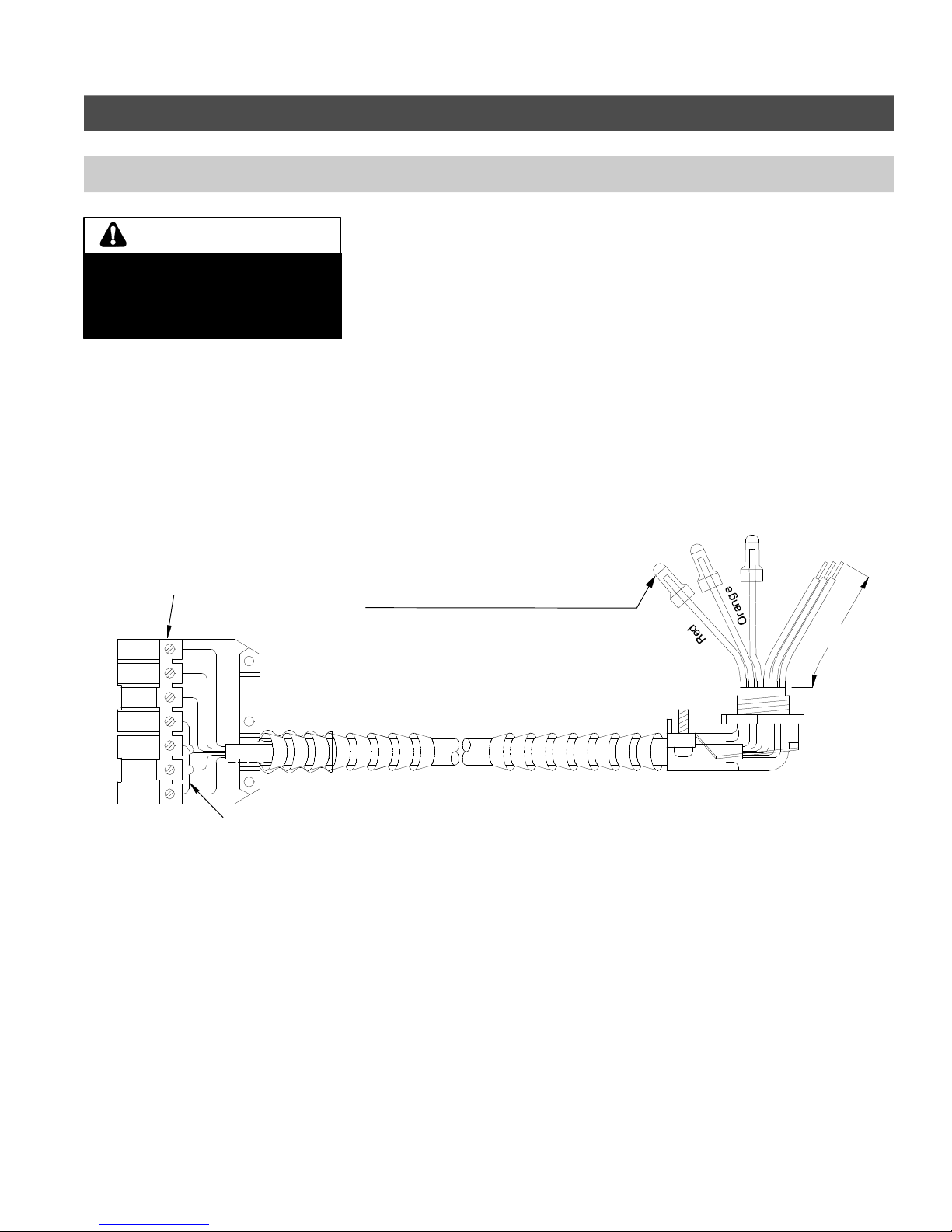

Legend

Cable strap (supplied)

Honeywell hi h limit control

Burner wirin harness (supplied)

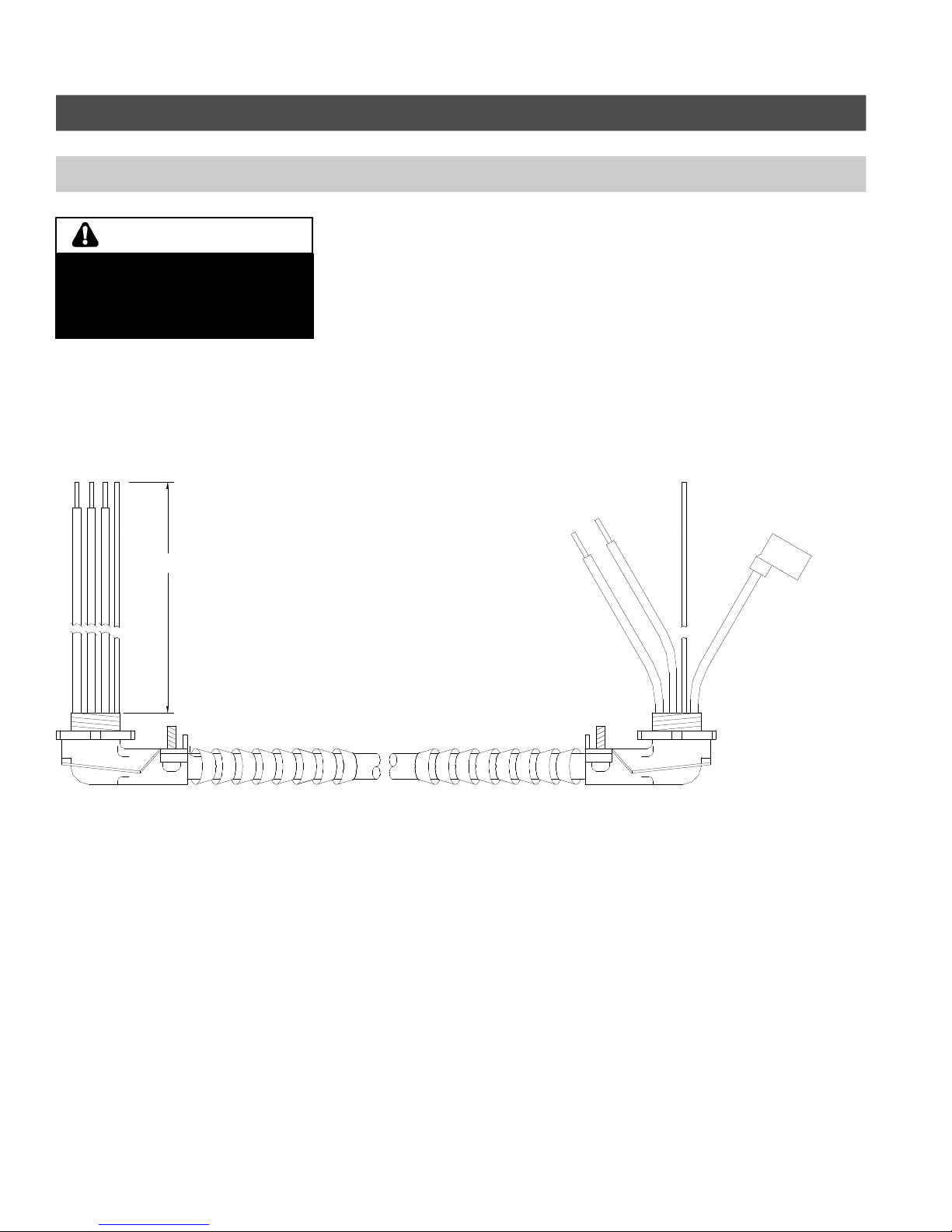

Burner wiring

The R7184 or GeniSys 7505P primary

control with valve-on delay (pre-purge)

and burner motor-off delay (post-purge

- factory default settings can be field

adjusted), requires a constant 120

VAC power source supplied to the

BLACK wire on the control (see wiring

diagram on following page).

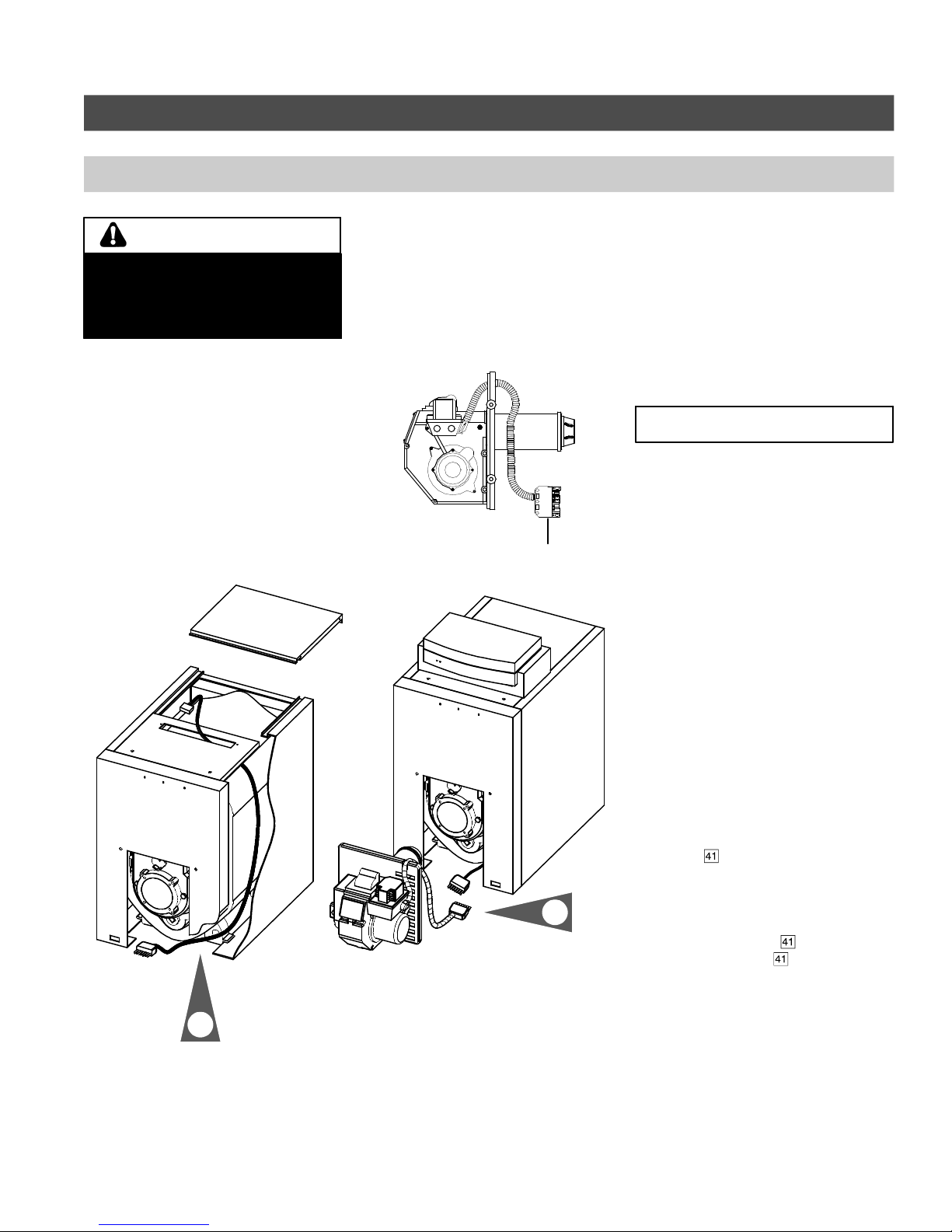

1. The cover mountin plate is not a

conduit connection point. Pass

conduit and attached connector

throu h the front openin in the

mountin plate or throu h one of the

knockouts on either side of the cover

and attach it directly to the

burner-mounted 4x4 electrical

junction box.

Room thermostat wiring

1. Install thermostat on inside wall

away from influences of drafts, hot

or cold water pipes, li htin fixtures,

television, sun rays or fireplaces.

2. Follow instructions supplied with

room thermostat. If it has a heat

anticipator, set heat anticipator in

thermostat to match power

requirements of equipment

connected to it. Boiler wirin

dia rams ive settin for standard

equipment.

5351 050 v2.5

Electric shock hazard. Can cause

severe personal injury or loss of life if

power source, including service

switch on boiler, is not disconnected

before installing or servicing.

WARN NG

Ensure that burner wiring harness is

properly attached and secured to the

boiler side panel using the supplied

cable straps as depicted above. The

cable strap must be coiled on the

boiler side panel so that no slack is

left, allowing the burner/boiler door

to be swung open without

disconnecting the burner wiring

harness from the burner. Failure to

heed this warning may result in

personal injury.

WARN NG

MPORTANT