4 / 47 eco-CONTROL EC200 DUOMIX INST-008759 / 0

TABLE OF CONTENTS

5.10 Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

5.10.1 Mixing ratio 22

5.10.2 Purge volume 22

5.10.3 Setting the pot life, purging the mixer 23

5.10.4 Setting the motor speed of the mixer 23

5.10.5 Dosing quantity 24

5.10.6 Dosing time 24

5.10.7 Flow rate 24

5.10.9 Dosing time 25

5.10.10 Dosing pressure monitoring 25

5.10.8 Suck-back 25

5.10.11 Tolerance value for inlet pressure monitoring 26

5.10.12 Password protection 26

5.10.13 Analog input 28

5.10.14 Time and date 29

5.10.15 System and error messages 30

5.11 Creating dosing programs - - - - - - - - - - - - - - - - - - - - - - - 31

5.12 Selecting the dosing program - - - - - - - - - - - - - - - - - - - - - 31

5.13 Copying the dosing program - - - - - - - - - - - - - - - - - - - - - 32

5.14 Changing a dosing program - - - - - - - - - - - - - - - - - - - - - - 32

5.15 Dosing, selected directly without dosing program - - - - - - - - - - - 34

5.16 Dosing, using a dosing program - - - - - - - - - - - - - - - - - - - - 34

5.17 Monitoring / displaying dosing pressure - - - - - - - - - - - - - - - - 35

5.18 Manual purging - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

5.19 Bleeding the 2-component dispenser after filling it for the first time or

after refilling it, and after cleaning - - - - - - - - - - - - - - - - - - - 36

5.20 Error messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

5.21 Acknowledging error messages - - - - - - - - - - - - - - - - - - - - 36

5.22 Error message – dosing pressure monitor fault - - - - - - - - - - - - 36

5.23 Service - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

5.23.1 Operating information 37

5.23.2 Formatting the memory card 37

6 Accessories / spare parts 38

7 Troubleshooting / maintenance 38

8 Technical data 39

8.1 Dosing control unit - - - - - - - - - - - - - - - - - - - - - - - - - - 39

8.2 2-component dispenser - - - - - - - - - - - - - - - - - - - - - - - - 39

8.3 Interface description - - - - - - - - - - - - - - - - - - - - - - - - - 40

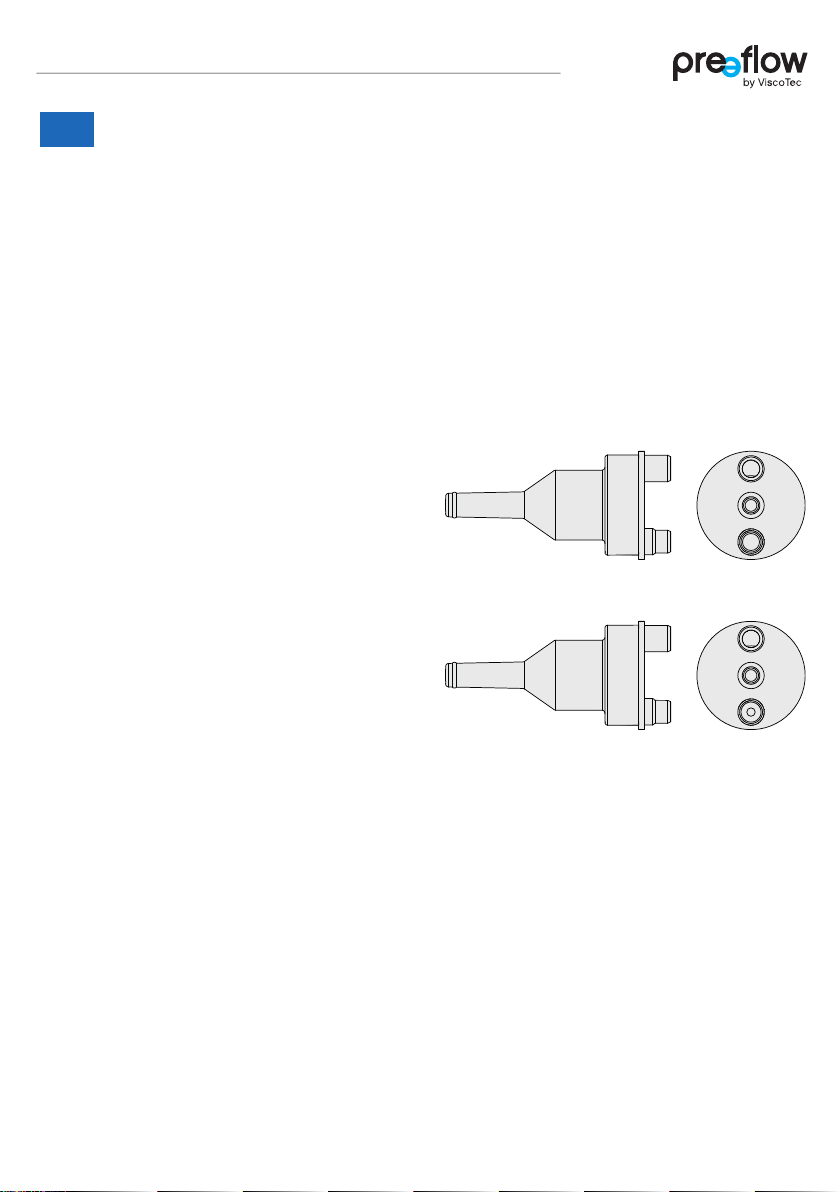

8.3.1 System plug 40

8.3.2 Logical links of the outputs 42

9 Disposal 46

10 EU Declaration of Conformity 47