Stuart Turner Monsoon Extra S1.4 bar User manual

INSTALLATION INSTRUCTIONS

SERVICE KIT - MONSOON EXTRA S1.4 bar SINGLE Part No. 28454

- MONSOON EXTRA U1.4 bar SINGLE Part No. 28455

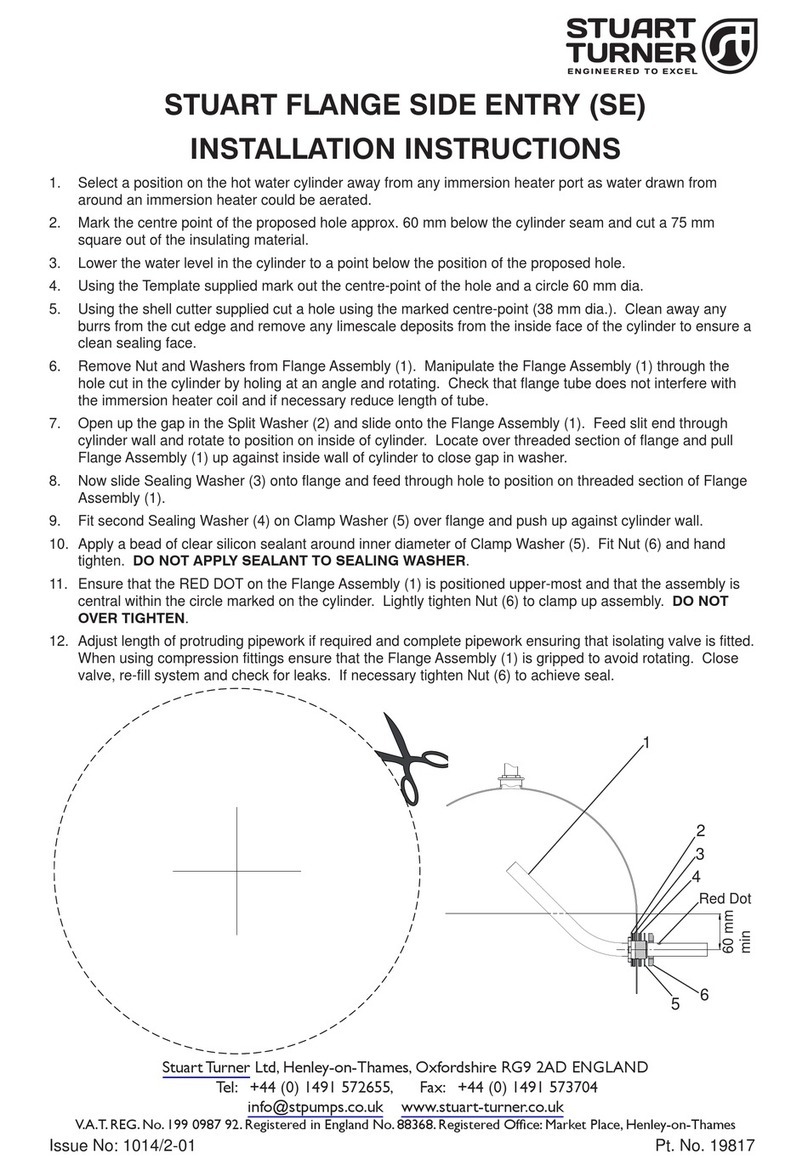

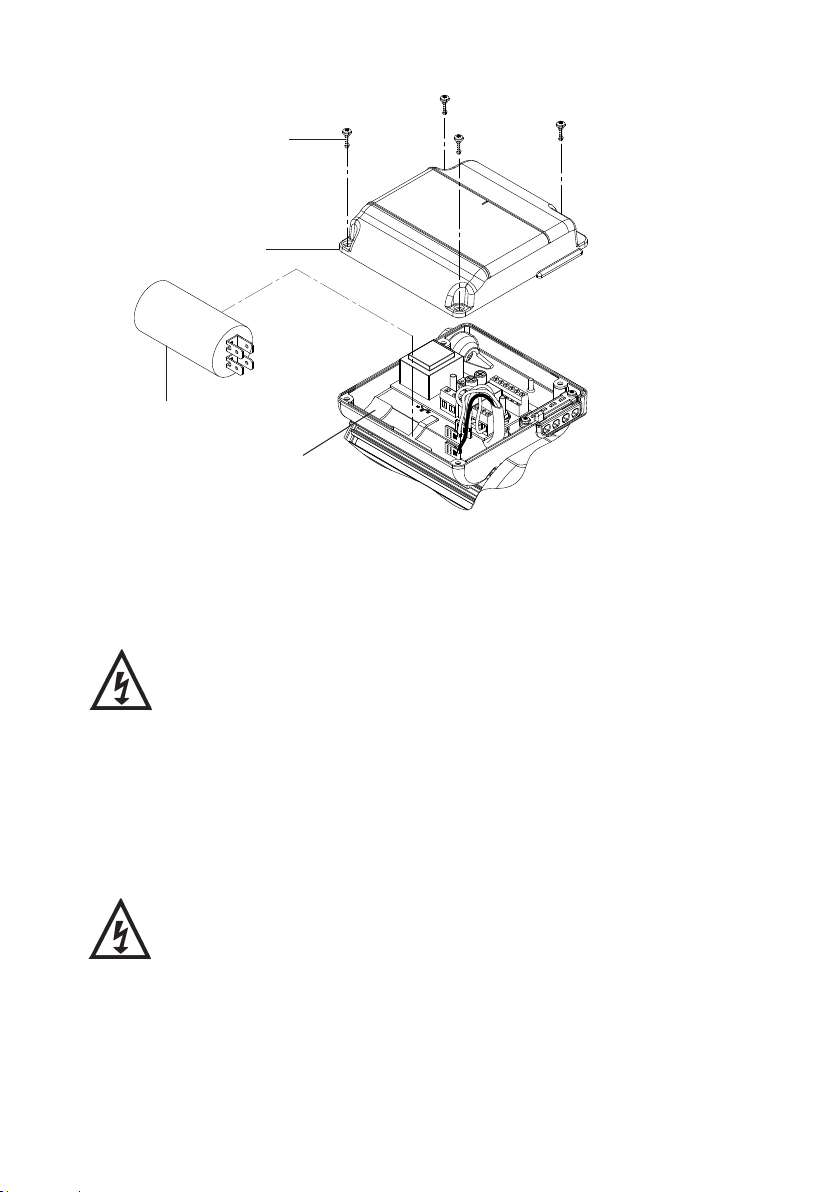

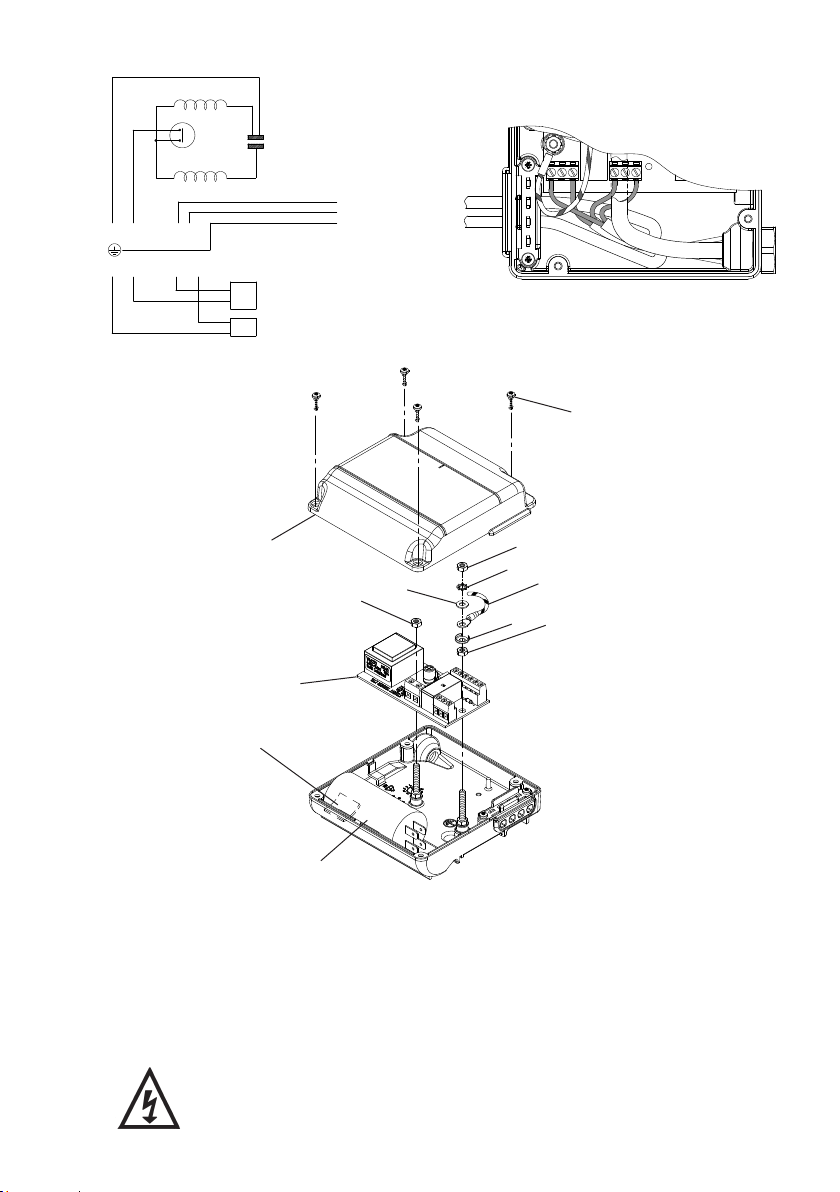

Fig. 1

23 Capacitor

(not shown)

25 Adhesive

foam pad

(not shown)

5 Rotary seal

4 Seal counterface

All Models - see Sections 1 & 5

1 Thrower washer

3 ‘O’-ring

(ID 101.4 mm) 6 Plastic

spacer

7 Stainless washer

7

8 M8 locknut

9 ‘O’-ring

(ID 8 mm)

2 ‘O’-ring

(ID 6.07 mm)

Additional Parts

Fig. 2

11 Reed switch tie

wrap

24 Reed switch

14 ‘O’-ring

(ID 29.1 mm)

22 Non-return valve

assembly

19 Pressure switch

18 Pressure

vessel (0.6 litre)

U1.4 only - see Sections 2, 3 & 4

10 or 16

13 Grub screws

(M4 x 4 mm)

15 ‘O’-ring

(ID 13.6 mm)

17 Rubber washer

(OD 18 mm)

20 1/8 seal

OR

21 ‘O’-ring

(ID 10.1 mm)

S1.4 only - see Sections 2 & 4

10 Fibre washer

(OD 38 mm)

OR

16 ‘O’-ring (ID 35.1 mm)

11 Reed switch

tie wrap

24 Reed switch

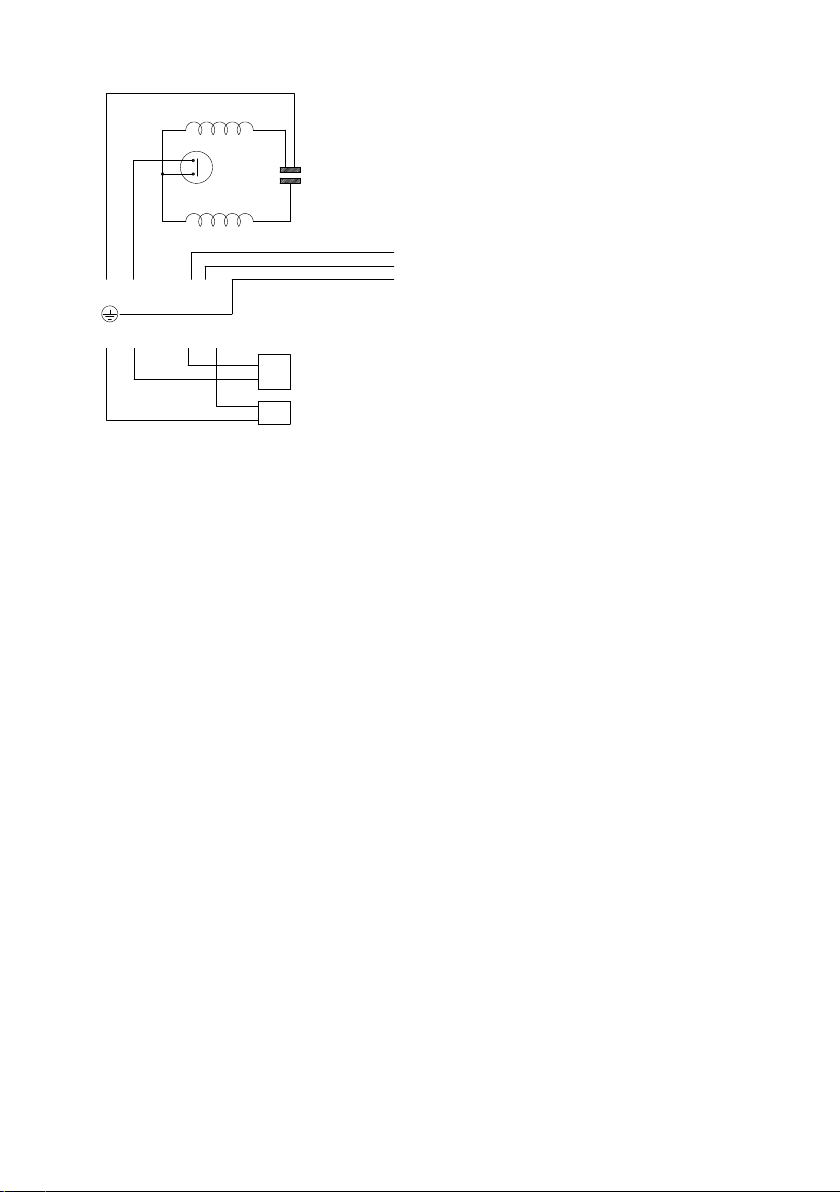

Fig. 3

10 or 16

27 Screws

(M6 x 35 mm)

28 Screws

(M6 x 16 mm)

26 Screws

(3.5 x 12 mm)

29 PCB (not shown)

- 2 -

Cont ...

• COMPLETE KIT CONTENTS

This kit contains parts for a range of different pump types - please ensure you correctly identify

the relevant parts for the pump being serviced before commencing. Also refer to the relevant

section for detailed instructions for the correct installation of the parts.

Fitting of incorrectly identified parts could lead to pump failure. If in doubt

contact PumpAssist on +44 (0) 800 31 969 80.

ITEM QTY ITEM QTY

1 Thrower Washer 1 16 ‘O’-Ring (ID 35.1 mm) 3

2 ‘O’-Ring (ID 6.07 mm) 2 17 Rubber Washer (OD 18 mm) 1

3 ‘O’-Ring (ID 101.4 mm) 1 18 Pressure Vessel (0.6 litre) 1

4 Seal Counterface 1 19 Pressure Switch 1

5 Rotary Seal Assembly 1 20 1/8 Seal 1

6 Plastic Spacer 1 21 ‘O’-Ring (ID 10.1 mm) 1

7 Stainless Washer 2 22 Non-Return Valve Assembly 1

8 M8 Locknut 1 23 Capacitor 1

9 ‘O’-Ring (ID 8 mm) 1 24 Reed Switch 1

10 Fibre Washer (OD 38 mm) 3 25 Adhesive Foam Pad 1

11 Reed Switch Tie Wrap 1 26 Screws (3.5 x 12 mm) 4

12 Applicator Tool (not shown) 1 27 Screws (M6 x 35 mm) 2

13 Grub Screws (M4 x 4 mm) 3 28 Screws (M6 x 16 mm) 4

14 ‘O’-Ring (ID 29.1 mm) 1 29 PCB 1

15 ‘O’-Ring (ID 13.6 mm) 1

Check to see that you have all the above items and that they are not damaged. If any damage is

found contact Stuart Turner Ltd within 24 hours of receipt.

• PUMP PREPARATION

To prepare the pump to accept the service kit parts, each pump part must be removed noting

its exact position and sequence (Figs. 1, 2 & 3).

Now clean all the individual parts. Before fitting the new service kit parts, the pump and seal

type must be identified.

• CONTENTS PAGE

Section 1 Mechanical seal replacement .................................. 3

Section 2 Non-return valve/pressure vessel replacement ..................... 4

Section 3 Pressure switch replacement................................... 6

Section 4 Reed switch replacement ..................................... 8

Section 5 Capacitor replacement ....................................... 11

Section 6 Printed circuit board replacement ............................... 13

- 3 -

Cont ...

A Seal seat complete with rubber cup washer.

B Rotary seal assembly.

C Spacer.

D Stainless steel washer.

• MAINTENANCE AND CARE UPON ASSEMBLY

To allow ease of assembly along with correct functioning of the pump, the following points on

assembly are necessary.

• All pump parts must be free from debris and assembled correctly.

• The seal must always be replaced as a complete unit using the seal applicator tool as

provided.

• The seal faces must not be handled or damaged.

To assemble the seal correctly, the shaft must be clean and the following steps carried out.

1 Use side 1 of the applicator tool to push the seal seat (item A) firmly into the housing

ensuring it is located flat against back of housing.

2 Now use side 2 of the applicator tool to push the rotary section of the seal assembly

(item B) onto the motor shaft until it is flat against the seal seat (Fig. 5). The shaft

may be lubricated with clean water to assist assembly.

Assemble the spring and location plate onto the shaft so as to complete the seal

bellows assembly (Fig. 6).

3 The spacer (item C) and washer (item D) can then be placed on the shaft and whole

assembly located into position by screwing the impeller to its stop. The impeller

locknut should then be secured (Fig. 7).

• INITIAL OPERATING INSTRUCTIONS

• Do not run pump dry. Allow the water to be pumped to enter the pump body thus ensuring

the seal is lubricated before switching the pump on. Failure to do this will damage the seal.

• Carefully check pump and pipework for leaks whilst pump running and stationary before

leaving the installation unattended.

SECTION 1 - MECHANICAL SEAL REPLACEMENT

The parts required to replace the seal are:

ITEM QTY ITEM QTY

1 Thrower Washer 1 7 Stainless Washer 2

2 ‘O’-Ring (ID 6.07 mm) 2 8 M8 Locknut 1

3 ‘O’-Ring (ID 101.4 mm) 1 9 ‘O’-Ring (ID 8 mm) 1

4 Seal Counterface 1 12 Applicator Tool (not shown) 1

5 Rotary Seal Assembly 1 27 Screws (M6 x 35 mm) 2

6 Plastic Spacer 1 28 Screws (M6 x 16 mm) 4

• SEAL IDENTIFICATION

For certain pump variants your seal arrangements may be different from that supplied within the

service kit.

The seal as supplied is an alternative and is shown in order of assembly in Fig 4.

Fig. 4 A B C D

Fig. 5 Fig. 6

Fig. 7

Side 2 Side 1

Applicator Tool (Item 12)

- 4 -

Cont ...

SECTION 2 - NON-RETURN VALVE/PRESSURE VESSEL

REPLACEMENT

The parts required to replace the non-return valve and pressure vessel are:

ITEM QTY ITEM QTY

10 Fibre Washer (OD 38 mm) 1 16 ‘O’-Ring (ID 35.1 mm) 1

13 Grub Screws (M4 x 4 mm) 3 17 Rubber Washer (OD 18 mm) 1

14 ‘O’-Ring (ID 29.1 mm) 1 18 Pressure Vessel (0.6 litre) 1

15 ‘O’-Ring (ID 13.6 mm) 1 22 NRV Body Assembly 1

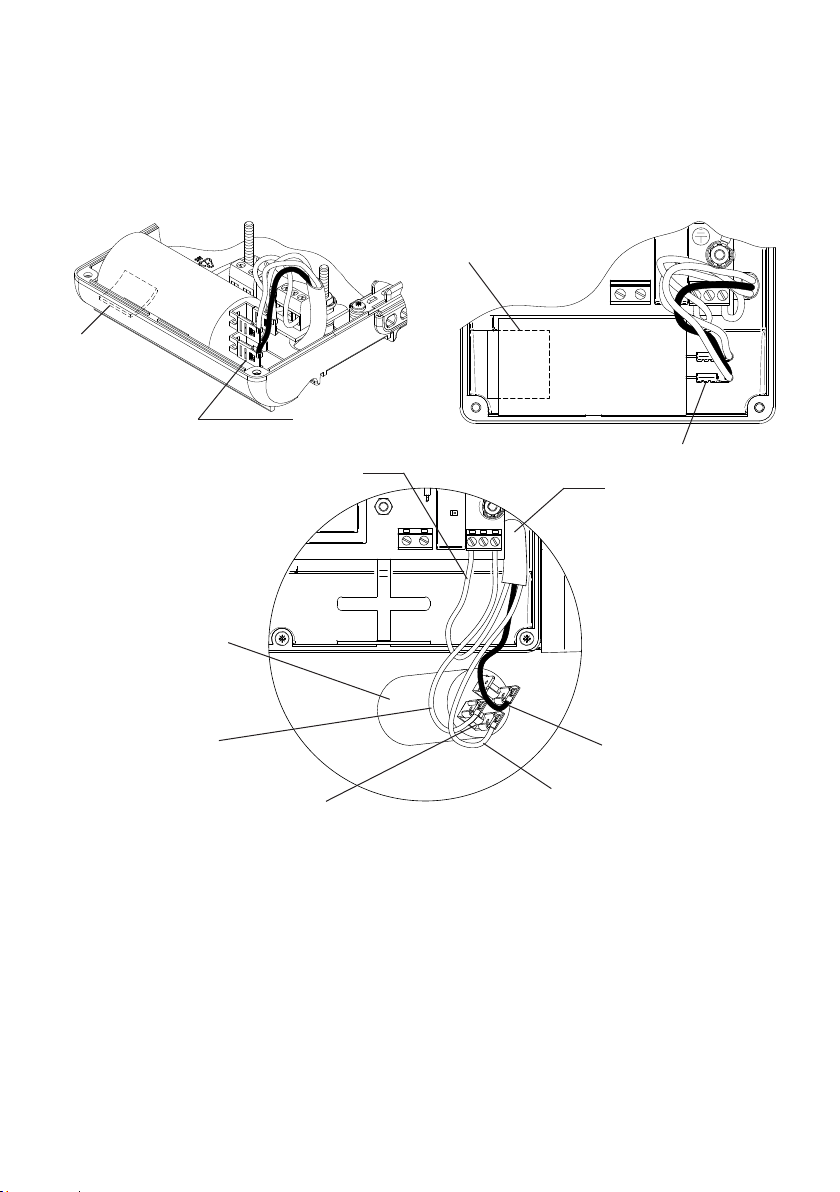

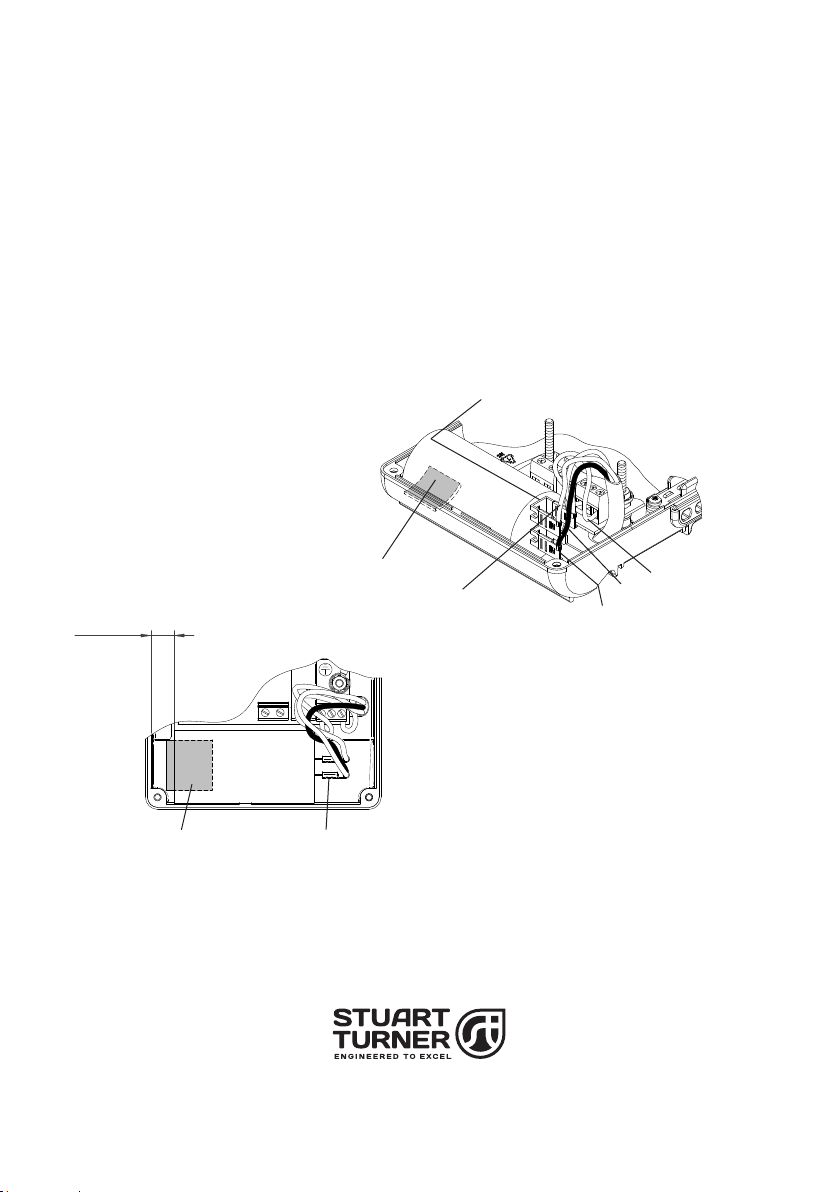

• DISASSEMBLY

Remove the following parts in the order shown:

1. Reed switch and tie wrap

2. Pressure vessel and ‘O’-ring (item 15)

3. 3 Grub screws (item 13) - 2 mm allen key required.

The flow switch assembly can now be removed from the NRV body being careful not to place

stress on the pressure switch cable. Note position of ‘O’-ring (item 14).

The NRV body assembly (item 22) can now be unscrewed from the pump head, noting the

position of ‘O’-ring (item 10 or 16).

Clean all parts that are to be re-used.

Damaged components must be replaced.

Contact Stuart Turner Ltd for replacements not supplied with kit.

Fig. 8

18

Reed Switch Tie Wrap

Flow Switch Assembly

Reed

Switch

13

10 or 16

22

14

Pressure Switch

15

17

- 5 -

Cont ...

• ASSEMBLY

Assembly is the reverse of the disassembly method.

Pressure vessel to be hand tightened.

Grub screws torque setting - 2.2 Nm

• PRESSURE VESSEL REPLACEMENT/CHARGE

Should ever the need arise for the vessel (item 18) to be replaced or have its air charge checked

or replenished, it should be carried out as follow:-

a) Isolate pump electrically.

b) Isolate hot and cold water supplies via the integral pump isolating valve

located in the flexible hoses.

c) Release system water pressure by opening a system outlet (tap).

d) Check air charge at Schrader valve using a tyre pressure gauge. The pressure should be set

at 0.9 bar (13 psi).

e) Replenish air charge if required by injecting air into the vessel via the Schrader valve using a

car or bicycle pump, ensuring a system outlet valve (tap) remains open during this procedure

to allow the vessel to exhaust any excess water.

f) Close all system taps, open hot and cold inlet pump isolating valves, turn on electrical power.

g) After maintenance is completed prime pump before re-starting.

• INITIAL OPERATING INSTRUCTIONS

• Do not run pump dry. Allow the water to be pumped to enter the pump body thus ensuring

the seal is lubricated before switching the pump on. Failure to do this will damage the seal.

• Carefully check pump and pipework for leaks whilst pump running and stationary before

leaving the installation unattended.

- 6 -

Cont ...

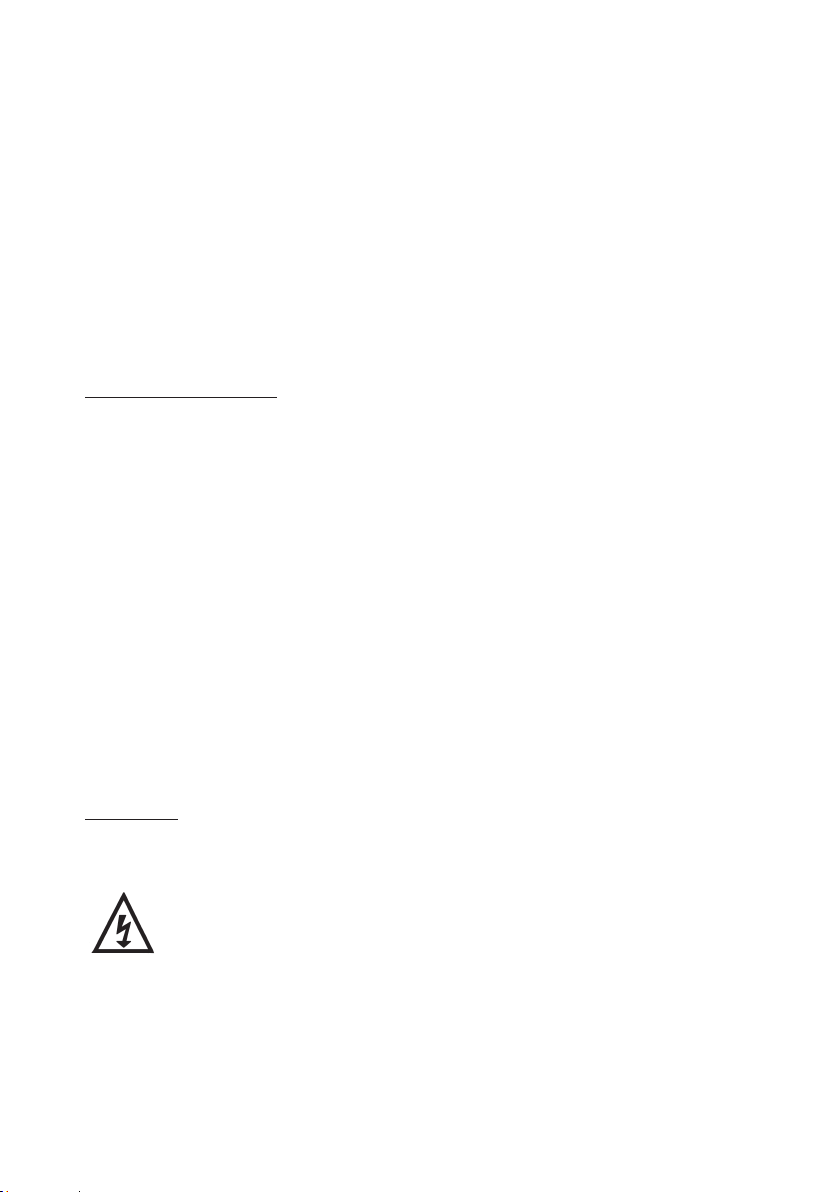

SECTION 3 - PRESSURE SWITCH REPLACEMENT

The parts required to replace the pressure switch are:

ITEM QTY ITEM QTY

19 Pressure Switch 1 21 ‘O’-Ring (ID 10.1 mm) 1

20 1/8 Seal 1

• DISASSEMBLY

• Isolate electrical supply before fitting.

• The supply cord and internal wiring within the terminal box are routed

and secured to ensure compliance with the electrical standard

EN 60335-1. It is essential that prior to any disturbance of this internal

wiring, all cable routing and securing details are carefully noted to

ensure re-assembly to the same factory pattern is always maintained.

To prepare the pump to accept the pressure switch, isolate and drain down the water. It may

be easier at this stage to remove the pump completely from its location.

Now disconnect the electrical connections from the pressure switch to the P.C.B.

The pressure switch cable restraint/sealing system will vary across model types.

Note the cable route, clamping and sealing method to enable re-assembly to same pattern

and proceed as follows:

The pump uses a rubber grommet for sealing and a cable strap for restraint. Release

cable strap and gently slide cable out through sealing grommet, to avoid damage to

enable re-use.

Damaged components must be replaced. Contact Stuart Turner for

replacements not supplied with kit.

Using a suitable open ended spanner (apply to brass switch part only), rotate the pressure

switch anticlockwise.

• MAINTENANCE AND CARE UPON ASSEMBLY

Depending on the age of your pump it may have a sealing washer (item 20) or ‘O’-ring (item 21)

always replace like for like.

Ensure the sealing faces for the pressure switch are clean before using the replacement sealing

washer.

Now tighten the pressure switch to 7 Nm torque.

Wiring of the switch can now be completed.

The strain relief bush, as supplied will suit the new switch and must be fitted.

2

1

Fig. 9

- 7 -

Cont ...

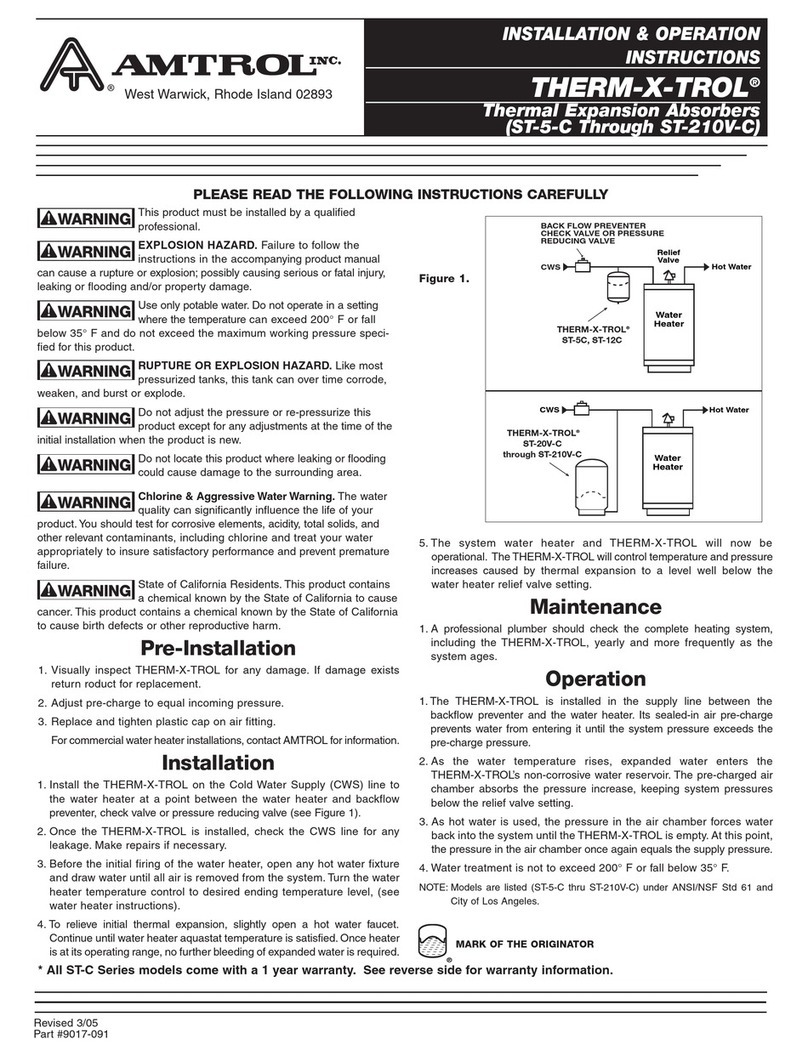

• WIRING DIAGRAM

• INITIAL OPERATING INSTRUCTIONS

1. Turn on water supply, prime and vent the pump via the vent plug. Unscrew slowly until

liquid emerges, then re-tighten.

Note: DO NOT RUN PUMP DRY.

2. Turn power supply to pump ‘on’ - pump will start, pressurise the system then stop.

3. Open and close all outlets in turn associated with the pump, (including w/c systems)

allowing water to flow from each outlet until all air is purged. As each outlet is opened

and closed, the pump will stop and start respectively.

Note: After closing the outlet there will be a small delay time before the pump stops, which

is normal.

4. Any tap or control valve within the system when opened and closed will now turn the pump

on/off. Providing this is the case the system is now operating correctly.

5. Carefully check pump and pipework for leaks whilst pump running and stationary before

leaving the installation unattended.

Fig. 10

MAIN WINDING

THERMOTRIP CAPACITOR

START WINDING

FLOWSWITCH

REED (S3)

LINK WIRE (BLUE)

BROWN

BLACK

GREEN / YELLOW

BLUE

BROWN L

E

N

230 VAC/1PH/50Hz

SUPPLY

BLUE

NMNL

S3 S3 S1

S1

PRESSURE

SWITCH (S1)

- 8 -

Cont ...

SECTION 4 - REED SWITCH REPLACEMENT

The parts required to replace the reed switch are:

ITEM QTY ITEM QTY

11 Reed Switch Tie Wrap 1 26 Screws (3.5 x 12 mm) 4

24 Reed Switch 1

• WIRING DIAGRAMS

Fig. Pump UK Eire

11 Monsoon Extra S1.4 bar Single ü ü

12 Monsoon Extra U1.4 bar Single ü ü

CAPACITOR

FLOWSWITCH

REED (S2)

LINK WIRE

BROWN

BLACK

GREEN / YELLOW

BLUE

BROWN L

S2 S2

E

N

230 VAC/1PH/50Hz

SUPPLY

BLUE

NMNL

FLOWSWITCH

REED (S2)

MOTOR

Fig. 11

CAPACITOR

FLOWSWITCH

REED (S3)

LINK WIRE (BLUE)

BROWN

BLACK

GREEN / YELLOW

BLUE

BROWN L

S3 S3

E

N

230 VAC/1PH/50Hz

SUPPLY

BLUE

NMNL

S1 S1

PRESSURE

SWITCH (S1)

PRESSURE

SWITCH (S1)

FLOWSWITCH

REED (S3)

MOTOR

Fig. 12

Cable clamp & screws

- 9 -

Cont ...

• DISASSEMBLY

• Isolate electrical supply before fitting replacement part.

• Replacing the reed switch components should only be carried out by a

competent person.

• The supply cord and internal wiring within the terminal box are routed

and secured to ensure compliance with the electrical standard

EN 60335-1. It is essential that prior to any disturbance of this internal

wiring, all cable routing and securing details are carefully noted to

ensure reassembly to the same factory pattern is always maintained.

• Remove four screws and carefully remove terminal box lid (item 26).

• Note the cable routing within the terminal box (Figs. 11 or 12).

• Identify, disconnect and remove the reed switch wiring from the terminal block (Figs. 11 or

12).

• IMPORTANT – take note of the cable clamp orientation before removal, as reassembly in

the original factory orientation is essential. Remove two screws and cable clamp, this

allows any reed or pressure switch cables to be removed from the terminal box (Fig. 13).

• Remove the reed switch cable from the terminal box by gently sliding the cable out

through the grommet, ensuring no damage to the grommet sealing area (Figs. 11 or 12).

• Remove the existing reed switch by cutting the securing tie wrap and pulling away from

the body Fig. 14.

Damaged components must be replaced. Contact Stuart Turner for advice

on replacements not supplied with kit.

LN

MN

Fig. 13

26

Cable clamp screws

Cable clamp

Cable Grommet

Terminal box lid

Fig. 14

Cut tie

wrap

- 10 -

Cont ...

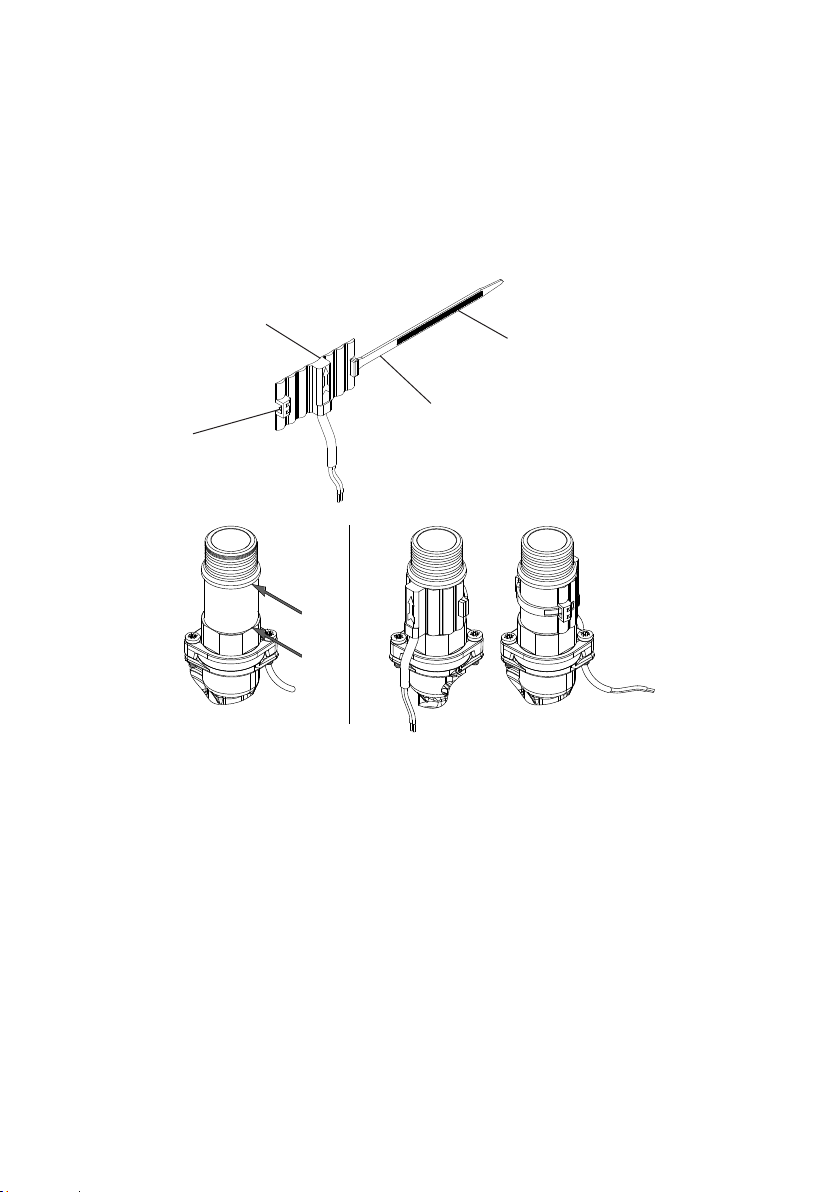

• REASSEMBLY

Reassembly is the reverse of the disassembly instructions with the new replacement parts

fitted as required.

Secure cable clamp screws and terminal box lid, to a torque of 0.8 Nm.

Note: For correct operation of the flow switch, the reed must be secured to the body as

detailed below.

Firstly feed the tie wrap through the retainer on the reed switch, ensuring that the tie wrap

serrations are facing outward (Fig 15).

Now locate the reed switch within the body groove as highlighted X-X (Fig. 16), and feed

the tie wrap through the second catch.

The tie wrap can now be pulled tight to secure the reed and the excess cut to length (Fig. 17).

• INITIAL OPERATING INSTRUCTIONS

• Consult instruction manual for commissioning instructions.

• Do not run pump dry. Allow the water to be pumped to enter the pump body thus ensuring

the seal is lubricated before switching the pump on. Failure to do this will damage the seal.

• Carefully check pump and pipework for leaks whilst pump running and stationary before

leaving the installation unattended.

Fig. 15

24

Catch

Serrations

11

X

X

Fig. 16 Fig. 17

- 11 -

Cont ...

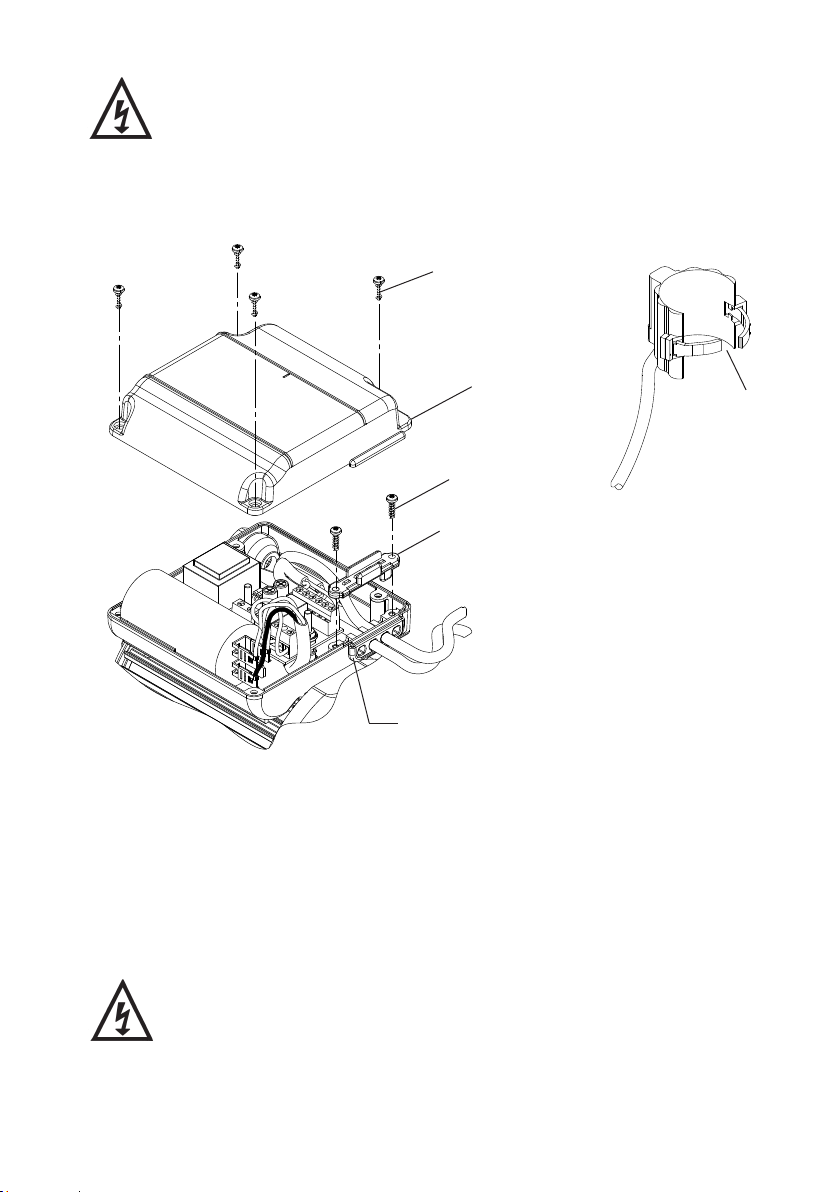

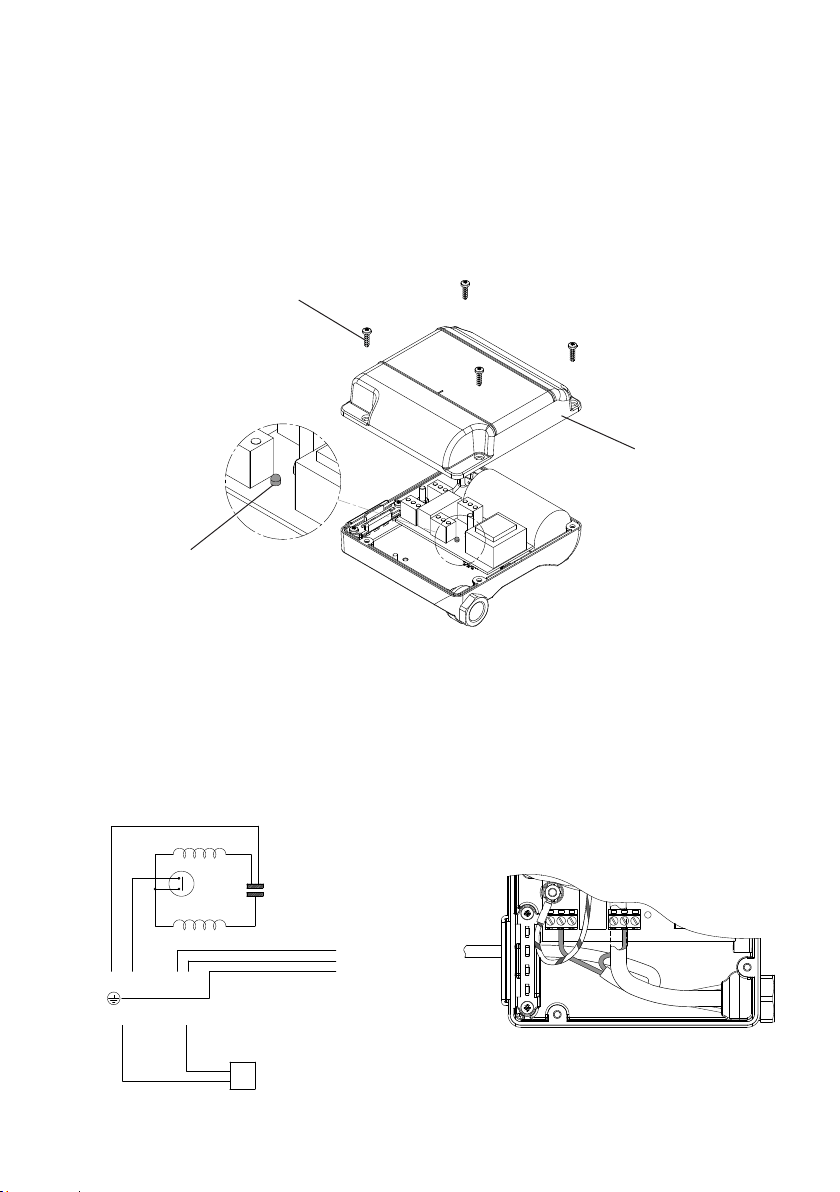

SECTION 5 - CAPACITOR REPLACEMENT

The parts required to replace the capacitor are:

ITEM QTY ITEM QTY

23 Capacitor 1 26 Screws (3.5 x 12 mm) 4

25 Adhesive Foam Pad 1

• DISASSEMBLY

• Isolate electrical supply before fitting replacement part.

• Replacing the capacitor, should only be carried out by a competent

person.

• The supply cord and internal wiring within the terminal box are routed

and secured to ensure compliance with the electrical standard

EN 60335-1. It is essential that prior to any disturbance of this internal

wiring, all cable routing and securing details are carefully noted to

ensure reassembly to the same factory pattern is always maintained.

Reference Fig 18:

• Remove 4 screws (item 26), and carefully remove terminal box lid.

• IMPORTANT: Take note of capacitor wiring connection and colours before removal.

Disconnect and remove capacitor (item 23) and foam securing pad (item 25), make note of

pad fitted position.

Damaged components must be replaced. Contact Stuart Turner for

advice on replacements not supplied with kit.

LN

MN

23

25

26

Terminal box lid

Fig. 18

- 12 -

Cont ...

• REASSEMBLY

Reassembly is the reverse of the disassembly instructions, with new replacement parts fitted

as required.

Note: For correct installation the capacitor must be connected, secured and positioned as

detailed (Figs. 19, 20 & 21).

Secure terminal box lid screws to a torque of 0.8 Nm (item 26).

IMPORTANT NOTE: For correct pump rotation, ensure both blue wires are connected to the

linked capacitor terminals as shown.

• INITIAL OPERATING INSTRUCTIONS

• Consult instruction manual for commissiong instructions.

• Do not run pump dry. Allow the water to be pumped to enter the pump body thus ensuring

the seal is lubricated before switching the pump on. Failure to do this will damage the

seal.

• Carefully check pump and pipework for leaks whilst pump running and stationary before

leaving the installation unattended.

N

L

M

N

N

A

M

NL

25

Receptacles upright

Receptacles upright

Fig. 19 Fig. 20

Fig. 21

25

Brown wire from motor

connect to ‘M’ terminal Protective supplementary

insulation surrounding

motor flying wires

Black wire from motor

Blue wire from motor

Linked terminal

Link wire blue connect

to ‘N’ terminal

23

- 13 -

Cont ...

SECTION 6 - PRINTED CIRCUIT BOARD REPLACEMENT

The parts required to replace the printed circuit board are:

ITEM QTY ITEM QTY

25 Adhesive Foam Pad 1 29 Printed Circuit Board 1

26 Screws, Self Tapping (3.5 x 12 mm) 4

Note: - When fitted this printed circuit board will detect the following fault conditions:

• Dry running caused by water starvation to the pump.

If the above fault condition occurs, then the pump will stop.

The fault should therefore be rectified before restarting the pump.

Check that there is sufficient water supply to the pump and also ensure that all outlets are

closed.

• Protective Logic Sequence

If water starvation occurs and the power supply to the pump remains uninterrupted, the pump

controller will perform the following protective sequence.

1) If the pump detects water starvation, it will stop operation after a 1 minute period.

2) The pump will remain in the off condition for a period of 5 minutes.

3) The pump will then re-start and if the water starvation condition remains present, the pump

will then stop operation after a 1 minute period.

4) The pump will remain in the off condition for a period of 5 minutes.

5) The pump will then re-start and if the water starvation condition remains present, the pump

will then stop operation after a 1 minute period.

6) The pump will remain in the off condition for a period of 5 minutes.

7) The pump will then re-start and if the water starvation condition remains present, the pump

will then stop operation after a 1 minute period.

8) After three consecutive resets are performed the pump will remain in the off condition

indefinitely.

9) To restart the pump, the power supply should be first isolated for a period of at least 10

seconds before switching on again.

If the pump fails to operate normally after three attempts to re-start, then please consult Stuart

Turner PumpAssist +44 (0) 800 31 969 80.

• Fault Finding

The PCB is also fitted with a “power on” indicator light. This will remain illuminated when

mains power is supplied to the board.

The indicator light is located on the PCB within the terminal box.

This operation should only be carried out by a competent person

- 14 -

Cont ...

To view the light the following procedure must be followed:-

• Isolate the mains electrical power supply from the pump.

• Remove the four screws (item 26) retaining the terminal box lid (Fig. 22).

• Lift the terminal box lid off.

• IMPORTANT – Ensure there is no contact with any of the internal parts of the terminal box.

• Briefly reconnect the mains power supply to the pump – the indicator light should illuminate if

the pump has been correctly wired.

• Isolate the mains electrical power supply from the pump.

• Re fit the terminal box lid ensuring no cables are trapped.

• Re fit the four terminal box lid retaining screws, tighten to 0.8 Nm.

• DISASSEMBLY

• Isolate electrical supply before fitting replacement part.

• Replacing the PCB should only be carried out by a competent person.

• The supply cord and internal wiring within the terminal box are routed

and secured to ensure compliance with the electrical standard

EN 60335-1. It is essential that prior to any disturbance of this internal

wiring, all cable routing and securing details are carefully noted to

ensure reassembly to the same factory pattern is always maintained.

Indication light

Terminal box lid

26

Fig. 22 Wiring removed for clarity

MAIN WINDING

THERMOTRIP CAPACITOR

START WINDING

LINK WIRE (BLUE)

BROWN

BLACK

GREEN / YELLOW

BLUE

BROWN

L

E

N230 VAC/1PH/50Hz

SUPPLY

BLUE

NMNL

S2 S2

FLOWSWITCH

REED (S2)

FLOWSWITCH

REED (S2)

S1 S2 S3 S3 S2 S1

Fig. 23

- 15 -

Cont ...

Reference Fig 25.

• Remove four screws (item 26) and carefully remove terminal box lid (item A).

• IMPORTANT: Take note of capacitor wiring connection and colours before removal.

• Disconnect and remove capacitor (item 23), and foam securing pad (item 25) make note of

pad fitted position.

• Remove M4 nut (item B) then M4 lock washer (item C) and plain washer (item D), this allows

removal of earth wire and cup washer (item E).

• Disconnect all wiring from terminal blocks on printed circuit board (PCB item 29).

• Remove two M4 nuts (item B) and carefully lift PCB (item 29) away from terminal box.

Damaged components must be replaced. Contact Stuart Turner for

advice on replacements not supplied with kit.

MAIN WINDING

THERMOTRIP CAPACITOR

START WINDING

FLOWSWITCH

REED (S3)

LINK WIRE (BLUE)

BROWN

BLACK

GREEN / YELLOW

BLUE

BROWN

L

E

N230 VAC/1PH/50Hz

SUPPLY

BLUE

NMNL

S3 S3 S1

S1

PRESSURE

SWITCH (S1)

PRESSURE

SWITCH (S1)

FLOWSWITCH

REED (S3)

S1 S2 S3 S3 S2 S1

Fig. 24

Fig. 25

26

AB

C

Earth wire

EB

D

B

29

25

Capacitor (item 23)

Stuart Turner Ltd, Henley-on-Thames, Oxfordshire RG9 2AD ENGLAND

Tel: +44 (0) 1491 572655, Fax: +44 (0) 1491 573704

[email protected] www.stuart-turner.co.uk

• REASSEMBLY

The replacement PCB supplied with this kit maybe of a different design to the PCB being

replaced. The new PCB is interchangeable with the existing, however, the following steps

must be adhered to.

Reassembly is the reverse of the disassembly instructions with the new replacement parts

fitted as required.

Note: For correct operation the capacitor must be secured and positioned as detailed in

Figs. 26 & 27.

The replacement PCB’s mains supply cord must be routed and secured as shown in Figs. 23 or

24.

Re-connect all internal wiring as detailed in appropriate wiring diagram and ensure the

internal wiring is routed and secured to the same pattern as noted in disassembly section

(except mains supply cord, see Figs. 23 or 24).

Secure PCB nuts to a torque of 1.5 Nm (item B).

Secure terminal box lid screws to a torque of 0.8 Nm (item 26).

IMPORTANT NOTE: For correct pump rotation, ensure both blue wires are connected to the

linked capacitor terminals as shown.

• INITIAL OPERATING INSTRUCTIONS

• Consult instruction manual for commissioning instructions.

• Do not run pump dry. Allow the water to be pumped to enter the pump body thus ensuring

the seal is lubricated before switching the pump on. Failure to do this will damage the seal.

• Carefully check pump and pipework for leaks whilst pump running and stationary before

leaving the installation unattended.

Stuart Turner Limited reserves the right to amend specifications without notice.

N

L

M

N

Fig. 26

Fig. 27

Linked Terminal

25

25

Blue

Receptacles Upright

Receptacles Upright

10.5 mm

9.5 mm

Blue

Black

Issue No: 1616/1-03

Pt. No. 20002

Other manuals for Monsoon Extra S1.4 bar

1

This manual suits for next models

1

Table of contents

Other Stuart Turner Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SYNAPTICON

SYNAPTICON SOMANET Circulo installation guide

Amtrol

Amtrol THERM-X-TROL ST-20V-C Installation & operation instructions

Mönninghoff

Mönninghoff HexaFlex 313. Series Operating and assembly instructions

Knick

Knick ProLine P16800 user manual

Angelus

Angelus 180S Service Notices

HappyJapan

HappyJapan HCR2 installation manual