Proper Disposal of Your Old Refrigeration Product

Suffocation Hazard

Remove doors from your old

refrigerator.

Failure to do so can result in

child entrapment, which can

cause death or brain damage

IMPORTANT: Child entrapment and suffocation are not problems of

the past. Junked or abandoned refrigerators are still dangerous, even

if they will sit for "just a few days." If you are getting rid of your

refrigeration product, please follow the instructions below to help

prevent accidents.

BEFORE YOU THROW AWAY YOUR OLD REFRIGERATION

PRODUCT:

•Take off the doors.

•Leave the shelves in place so that children may not easily climb inside.

\\

BU ILT-IN INSTALLATION

Select Location

The proper location will ensure peak performance of your appliance. Choose a location where the unit will be out of

direct sunlight and away from heat sources. Units with fan cooled condensers can be built-in.

Unit should be operated in a properly ventilated area with ambient temperatures above 40°F (4.4°C) and below

110°F (43°C). Installation should be such that the cabinet can be moved for servicing if necessary.

Cabinet Clearance

Ventilation is required from the bottom front section of the unit. Keep this area open and clear of any obstructions.

The adjacent cabinets and countertop can be built around the unit as long as no top trim or counter top is installed

lower than the top of the hinge.

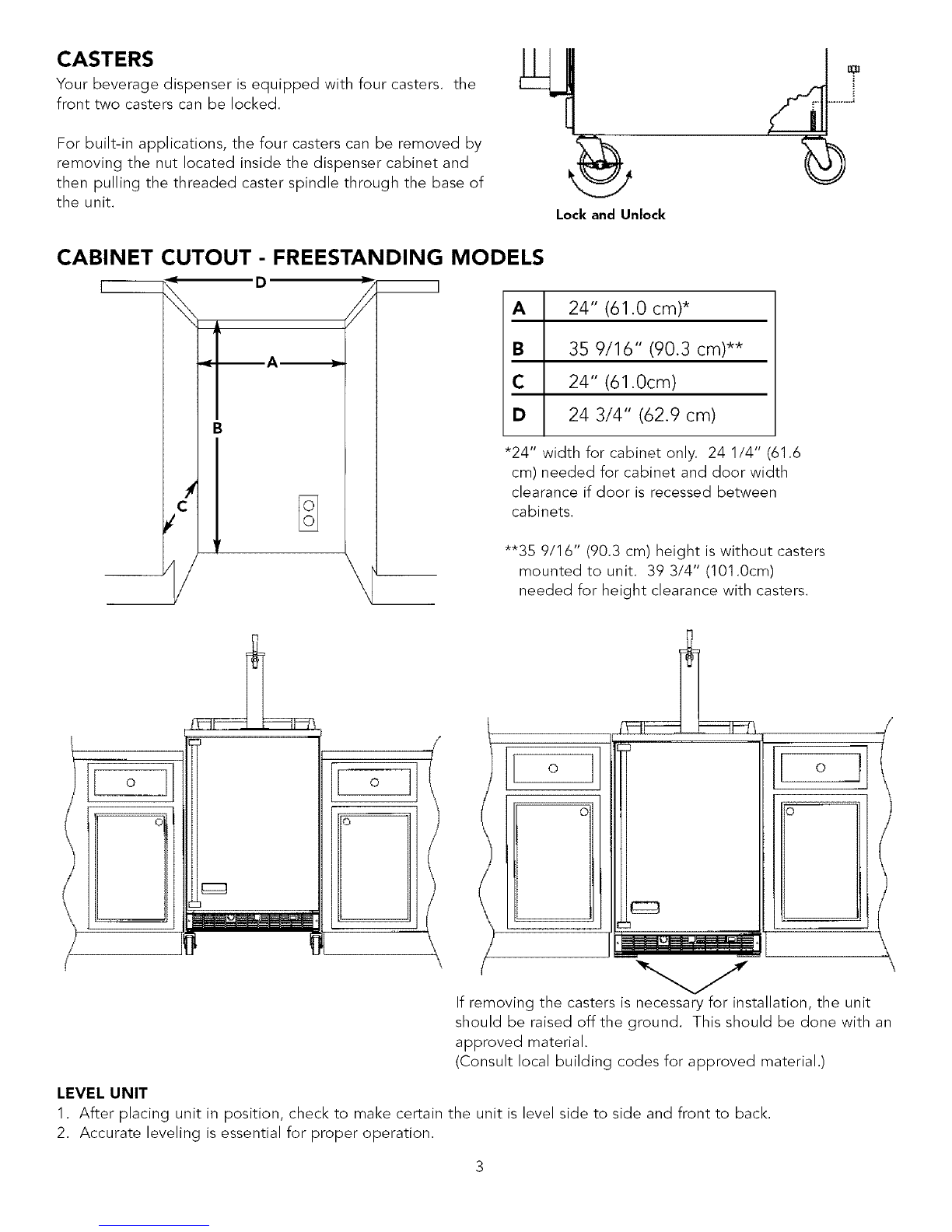

ELECTRICAL CONNECTION

Electrical Requirements

A 115 volt, 60 Hz, AC only 15 amp fused electrical supply is required. (A

time delay fuse or circuit breaker is recommended.) It is recommended

that a separate circuit, serving only this appliance, be provided.

*ELECTRICAL GROUND IS REQUIRED ON THIS APPLIANCE.

*DO NOT UNDER ANY CIRCUMSTANCES REMOVE THE POWER

SUPPLYCORD GROUND PLUG.

*DO NOT USE AN EXTENSION CORD.

Recommended Grounding Methods

PowerSupply

with 3-prong

grounding plug

\

For your personal safety,this unit must be grounded. This appliance isequipped with a

power supply cord having a 3-prong grounding plug. To minimize possible shock hazard,

the cord must be plugged into a mating 3-prong grounding type wall receptacle

grounded in accordance with the National Electrical Code and local codes and ordinances.

If the circuit does not have a grounding type receptacle, it isthe responsibility and

obligation of the customer to exchange the existing receptacle in accordance with the

National Electrical Code and applicable local codes and ordinances. The third ground

plug SHOULD NOT, under any circumstances, be cut or removed. All UL listed

refrigerated products are equipped with this type of plug. 2

Grounding type wall

receptacle

\k

Electrical Shock Hazard

Do not splash or spray water

from a hose on a refrigerated

unit. Doing so may cause an

electrical shock which may

result in severe injury or death.