aOperatlon of Your Motor

BREAK.IN PERIOD

Reasonable care in the operatlon of the motor during

the first several hours of use will improve its per-

formance and insure Ionger life. Follow the oiling

instructions carefully, Do not run continuously atfull

speed for the first few hours, to give the rings and

bearings a chance to become well seated. The motor

may not develop full speed and power until after ap-

pro>dmately 20 hours operation. No extra oil is

required for the break-in period.

STARTING AND OPERATING INSTRUCTIONS

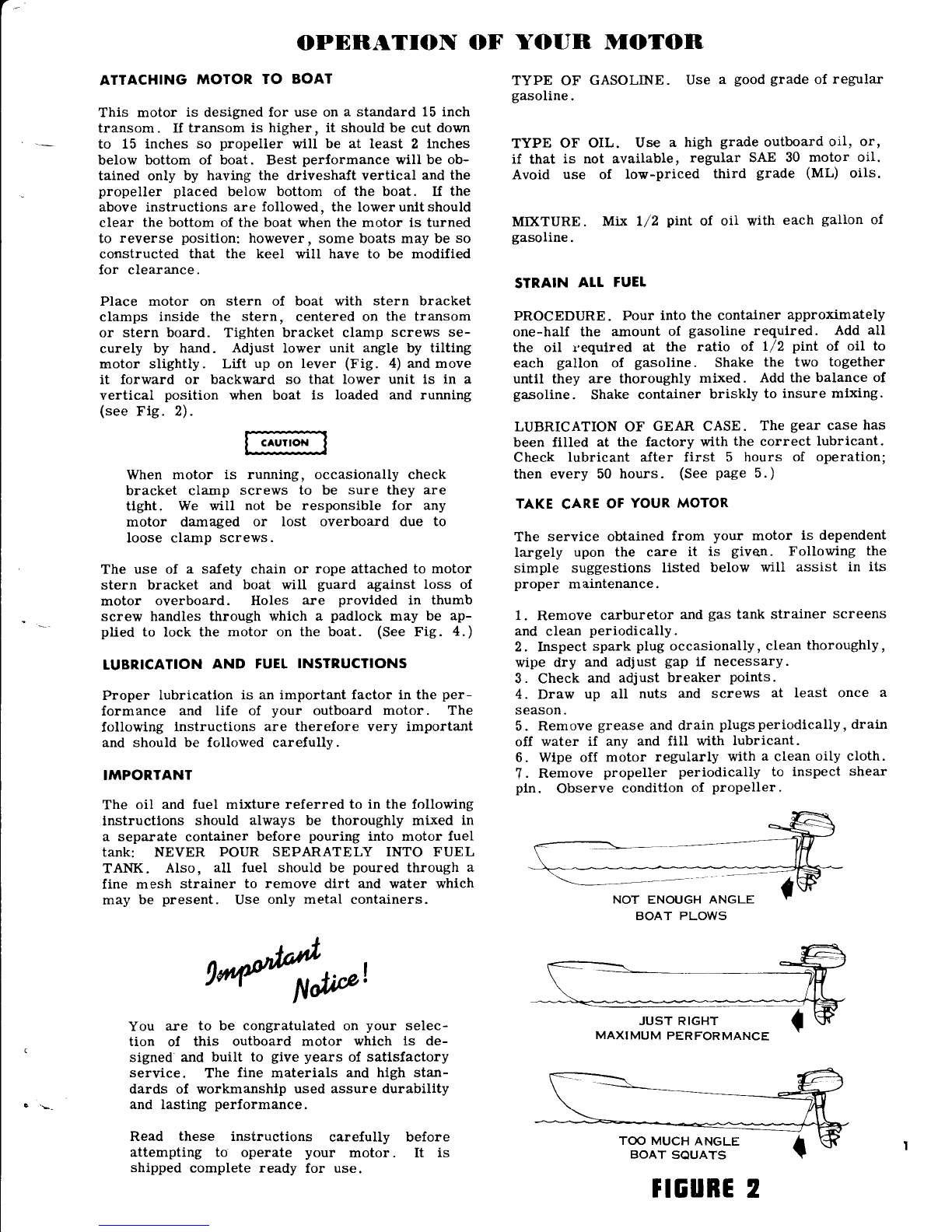

See Fig. 3.

1. Open air vent screw in fuel tank filler cap.

2. Open fuel shut-off valve under fuel tank.

3. Move speed control lever to position marked

START.

4. Turn carburetor knob to left or PRIME position

and hold down against spring pressure for 10seconds;

then release.

5. PulI starter handle slowly until starter engages,

then pull forcibly. If motor does not start after

several pulls, repedt priming instructions. Allow

starter cord to rewind before releasinghandle. Also,

do not pull cord out more than 30 inches-

6. After motor stalts, turn carburetor knob slowly

to right until motor runs smoothly. Advance speed

control lever as desired.

?. Advance speed eontrol lever to FAST position

and adjust carburetor knob until motor runs smoothly.

Since the speed control lever and carburetor control

are synchronized, the full range of speed is obtained

without further adjustment of the carburetor knob,

except when under unusual conditions.

8. To stop motor, move speed control Iever to

position marked STOP or beyond.

NOTE

The above starting instructlons are given in

step by step form - it is advisable to become

familiar with each detail prior to actually

operating the motor. A few moments spent

in practice are well worth while.

ArRvENr-,/"til

scREw €trf*f

,: .iliitir:q:'

WARIYI MOTOR

It is not necessary to prime motor when starting i-f

motor has be-en warmed up. Motor can usually be

started with carburetor knob in running position

and pulling starter handle with speed control lever

at START position.

FIOODING

Flooding may occur by over-priming or priming a

warm motor. If this occurs, turn carburetor knob

to extreme right (Iean posltton) and pull starter

handle several times. When motor starts, allow to

run until it stops. Then follow instructions for start-

ing cold or warm motor, whichever applies.

REVERSE

An important feature of the motor is that it can be

turned completely around in its pivot bearing, per-

mitting backing up and easy maneuverability. To

reverse, simply raise the steering handle and turn

the motor around to REVERSE position. With the

motor in reverse position, the reverse lock (Fig.

4) prevents the thrust of the propeller from forclng

the lower unit out of the water. The reverse lock

should be kept lubricated with grease and checked

periodically for proper operation. For SAFETY SAKE

do not attempt to reverse motor at any speed higher

than haU throttle.

l*"*f

I c^Utrox I

(

--.!

Be careful not to strike submergedobstruction

when in REVERSE - motor does not tilt

in reverse position.

RE'VTOVING

TVIOTORFROII BOAT

When removlng motor from boat, llft motor i.n a

straight upward position and hold this posltion for

a brief period until all water is drained from the

underwater exhaust tube and water cooling system.

Do not stand motor on magneto or carry with the

magneto down before drainlng water, as this may

allow water to enter the powerhead from under-

STARTER

HANDLE

water exhaust tube. Toward enct of

run, juat before etopplngmotor, cloee

FUEL SHTIT-OFF VALVE andpermit

motor to run until it Btopa, dralning

carburetor. Cloee carburetor adJuet-

lng knob and vent screw ln flller cap.

The motor can then be carrted wlth-

out leakage. For complete eafety,

empty fuel tank when transportlng

motor,

SPEED

CONTROL LEVER STEERING

tr

rA4:r

-a

./

FUEL ./

SHUT-OFF

VALVE ]IEURE

I