Page 4

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

T

elephone:

269-945-9501

T

echnical

Services

877-384-5464

Fax:

269-945-4495

Email:

[email protected]ESFR PRE-PRIMED SINGLE

INTERLOCK PREACTION

COLD STORAGE SYSTEM

March 7, 2008

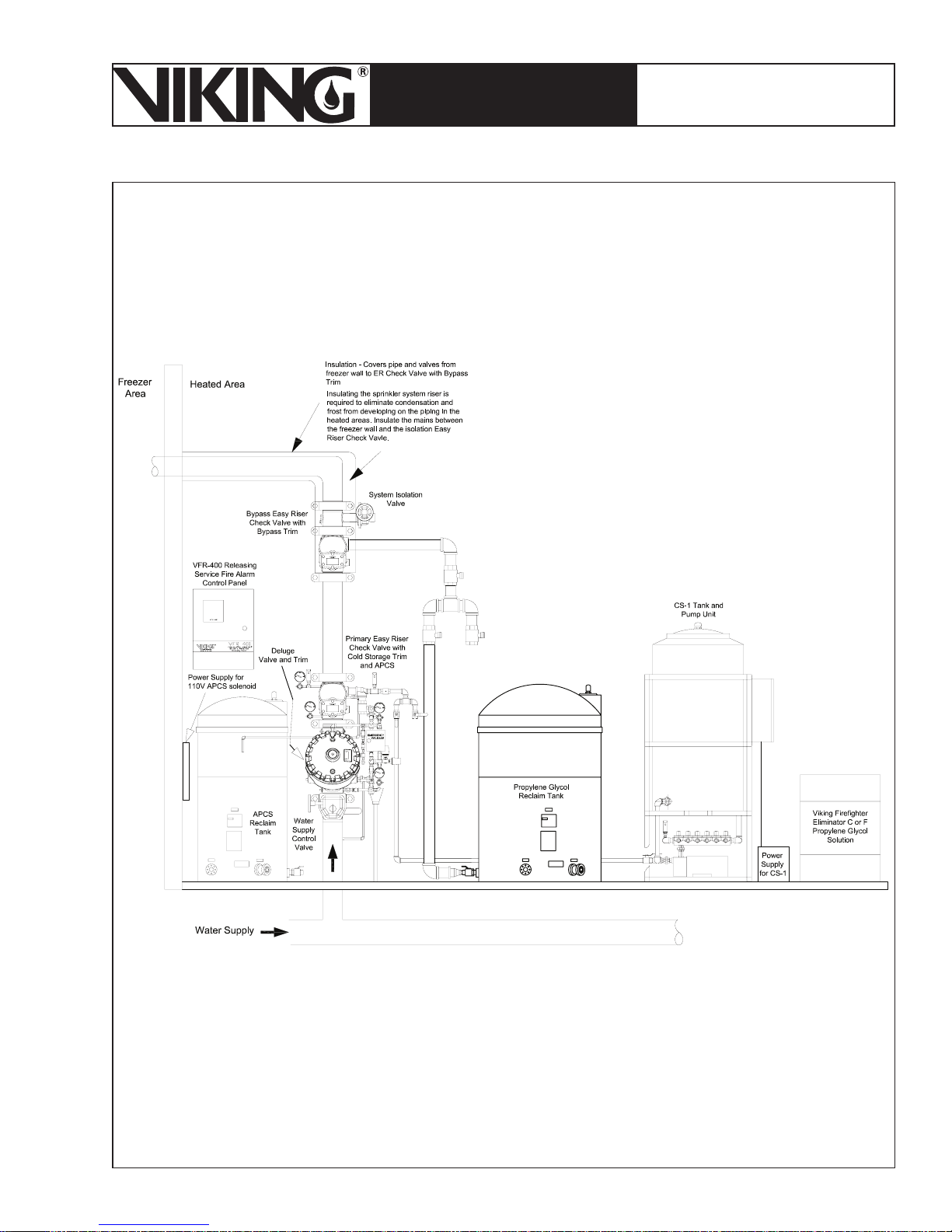

I. SYSTEM DESCRIPTION

The Viking ESFR Pre-Primed Single Interlock Preaction Cold Storage System is a fixed fire protection

system designed for installation in refrigerated, cold storage and unheated warehouse applications

with rack storage of Class II commodity on wood pallets. This system effectively prevents frost plugs

associated with systems that supervise the piping network with air. The single interlock preaction sys-

tem piping network is supervised with a propylene glycol solution. When using this system for single-,

double- and multiple-row rack storage, Viking K25.2 ESFR sprinklers are used at the ceiling only and

no in-rack sprinklers are required.

1. System Considerations

All materials installed on the system shall be compatible with propylene glycol solution.

Where the minimum temperature in the area being protected is 8 °F (-13.3 °C) or above,

Firefighter Eliminator C 35% percent by volume propylene glycol factory premixed solution

must be used.

Where the minimum temperature in the area is between 8 °F (-13.3 °C) and -21 °F (-29.4 °C),

firefighter Eliminator F 50% percent by volume propylene glycol factory premixed solution

must be used.

The minimum ambient temperature where the system can be used is -21 °F (-29.4 °C). This

is not an average temperature; it is the lowest temperature within the area.

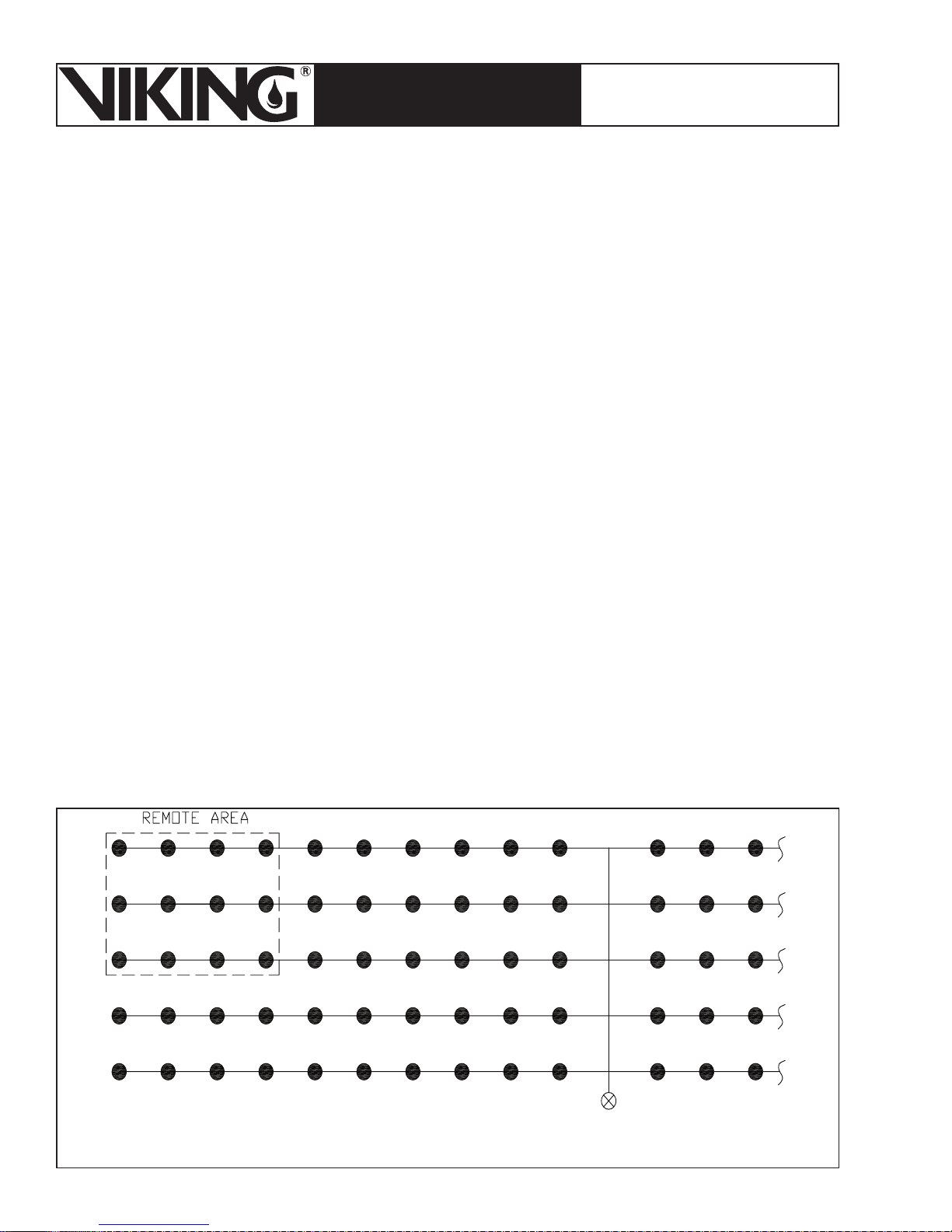

The system piping configuration shall be designed in a tree configuration only. The

mains and branch lines should not be looped together. Grid systems are NOT allowed. The

piping system shall be pitched to drain completely. The branch lines shall be pitched at ¼”

per 10 ft (4 mm/m) run of pipe and the mains shall be pitched ½” per 10 ft (4 mm/m) run of

pipe.

2. System Makeup

Each Viking ESFR Pre-Primed Single Interlock Preaction Cold Storage System requires the fol-

lowing components for proper operation:

Water Supply Control Valve

Deluge Valve with Conventional Deluge Valve Trim

Electric Release Trim with Solenoid Valve

Primary Easy Riser®Check Valve with Cold Storage Trim including Automatic Pressure

Control Trim

Bypass Easy Riser®Check Valve with Bypass Trim

Digital Supervisory Pressure Switch

CS-1 Tank and Pump Package

Viking VFR-400 Release Control Panel

Reclaim tank for Automatic Pressure Control System

System Reclaim Tank (Recommended)

AV-1 Automatic Air Vent (One for each high point recommended)

Firefighter Eliminator Propylene Glycol Solution

K25.2 ESFR Pendent Sprinklers (Viking VK510)

**Please see Appendix A for Material Selection

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•