3

Safety

Important information on the safe installation and operation of

this product. Read this information before operating the product.

For your personal safety, read these instructions.

The instructions must be followed in the order they are

presented.

Do not operate the product if you do not understand how to use

it safely. Save these instructions for future reference.

Warning Symbols Used in these Instructions

Safety cautions are included in these instructions. These safety

instructions must be followed to avoid possible personal injury and

avoid possible damage to the product.

!

WARNING!

Where there is a risk of personal injury or injury to

others, comments appear supported by the warning

triangle symbol.

Where there is a risk of damage to the product,

associated equipment, process or surroundings,

comments appear supported by the word ‘CAUTION’.

ELECTRIC SHOCK

Where there is a risk of electric shock, comments

appear supported by the hazardous voltage warning

triangle.

WARNING! Risk of electric shock. Always disconnect and

isolate the product from the power supply before attempting

any servicing or removing the covers.

!CAUTION! This product must be connected to a power

supply of the same voltage (V) and current (A) as indicated

on the product. Refer to the technical specications for the

product.

Intended Use

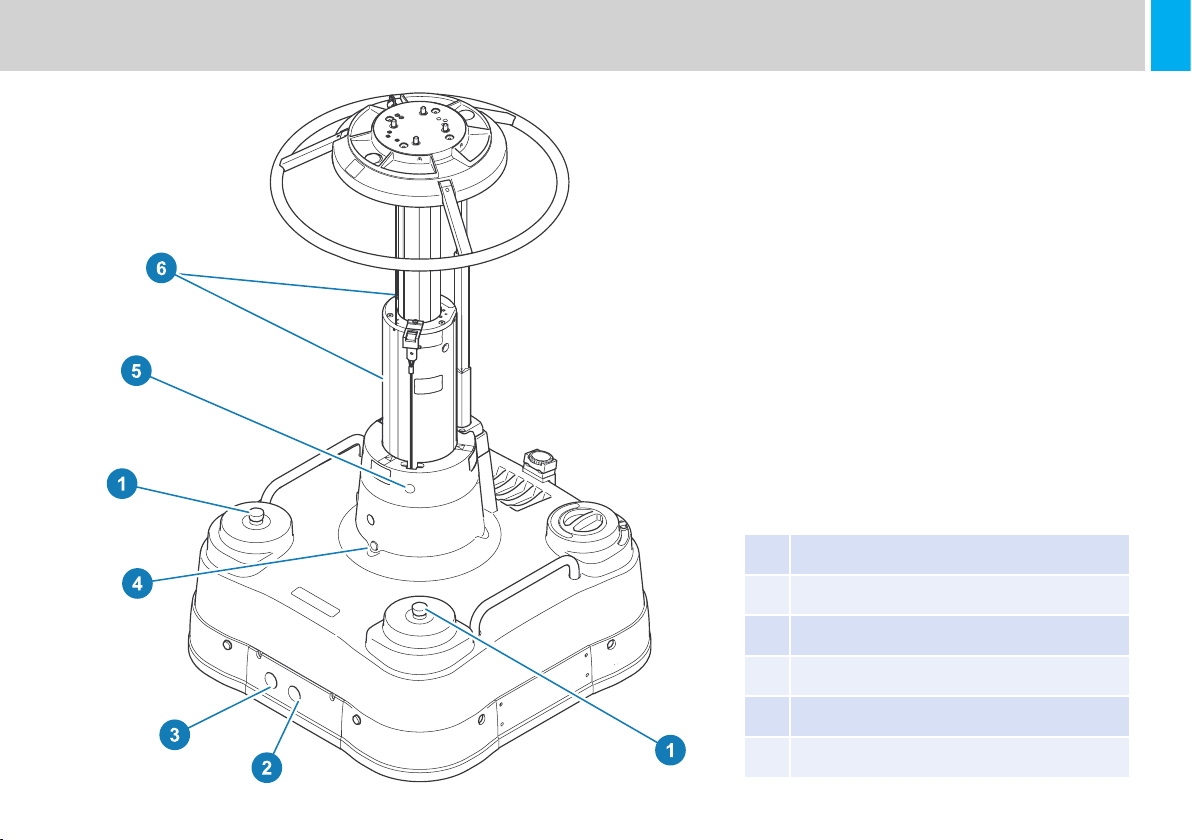

The FP-210+ is designed for use within television studios, supporting

a payload weighing up to 95 kg (210 lb). The total payload must

not be exceeded. The operator can remotely control the pedestal

movements and positioning around the studio as well as controlling it

manually.

This product is intended for use by television camera operators

trained to use Vinten robotic equipment. Do not use this product for

any other purpose other than that specied in this usage statement.

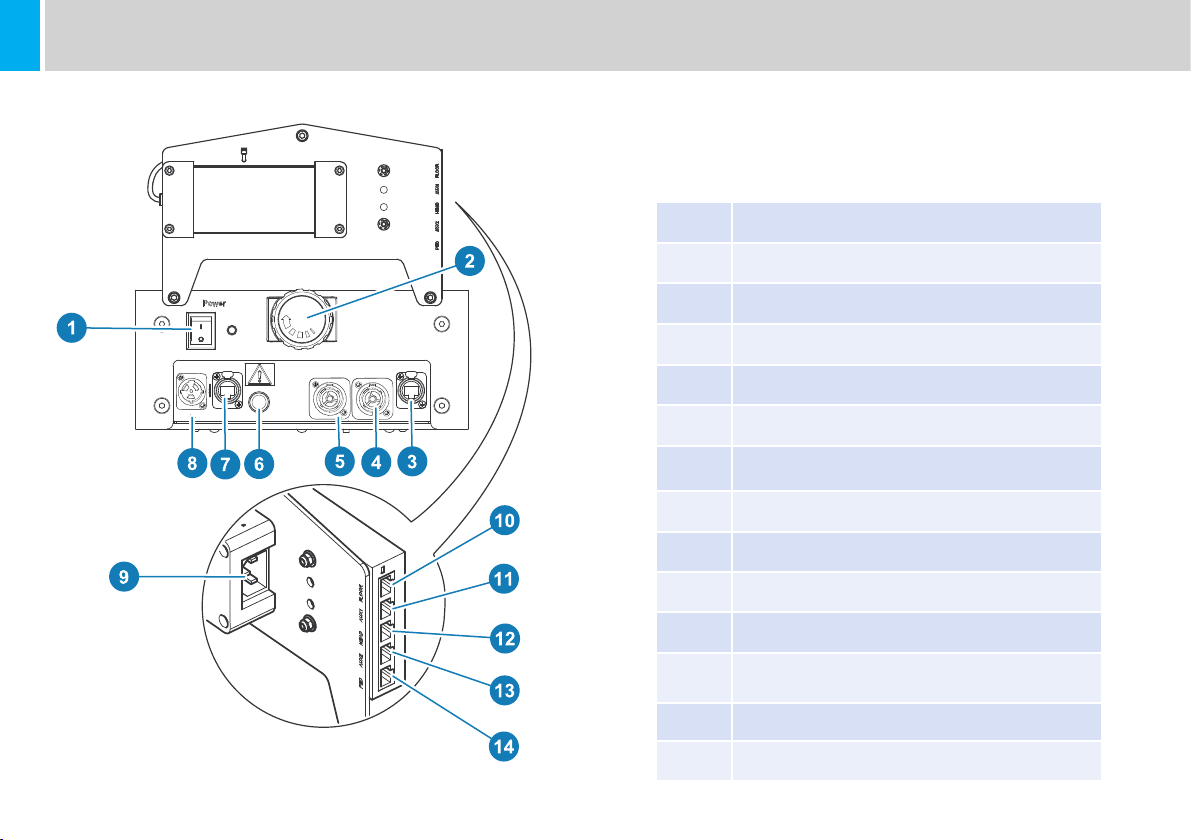

Electrical Connection

WARNING! Risk of electric shock. Always check cables for

signs of damage. Damaged cables can cause personal injury

and/or damage the equipment.

WARNING! It is the responsibility of the local organisation to

ensure that the product is periodically checked for electrical

safety in accordance with local regulations.

!CAUTION! All connections to other devices must be made

using shielded cables.

!CAUTION! Using alternative power sources will invalidate

the system EMC liability.

!CAUTION! Do not exceed the current output limit of the

product when powering auxiliary devices.

!CAUTION! Always use a fuse of the correct type and rating

for the product. Refer to the Technical Specications for the

product.

!CAUTION! The product must be connected to the AC supply

using a 30 mA RCD unit.