3

Range Owner’s Manual Rev 20190121

Table of Contents

Functional Introduction---------------------------------------------------------------------Page 4

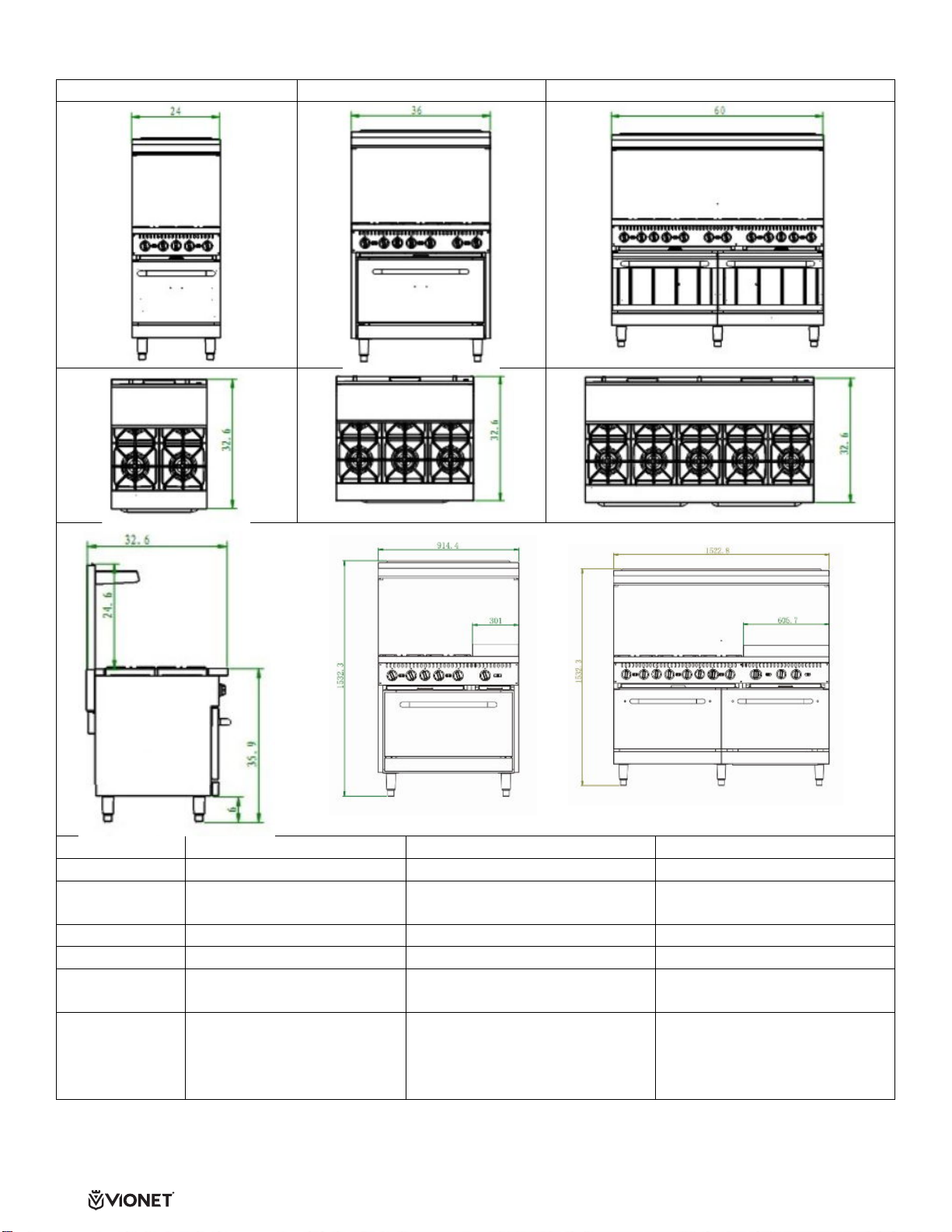

Specification & Diagrams -----------------------------------------------------------------Page 5

Installation-------------------------------------------------------------------------------------Page 8

Precautions & Recommendations ------------------------------------------------------Page 8

Operation--------------------------------------------------------------------------------------Page 9

Routine Inspection --------------------------------------------------------------------------Page 12

Cleaning & Maintenance ------------------------------------------------------------------Page 12

Failure Analysis & Trouble Shooting---------------------------------------------------Page 14

Warranty Information-----------------------------------------------------------------------Page 15

Any self-modification, wrong installation, adjustment or maintenance can lead to property loss

or casualty. Please contact the manufacturer for any adjustment or maintenance, and have the

work done by a trained & qualified person.

For your safety sake, please keep the machine away from any liquid, gas or other object which

is flammable or explosive.

This appliance should not be operated by those who have physiological, perceptual or mental

disabilities or those who have insufficient experience or knowledge (including children). Only in

conditions of being given sufficient supervision & guarantee of personal safety, as well as

proper instructions & guidance, those who were mentioned above can make some particular

operation of this device.

Keep children away from the device.

Preserve this manual safely. When passing on/selling the device to a third party, the manuals

must be handed over along with the device. All users must operate the device complying with

the user’s manual and related safety guidelines.

If the appliance is placed near walls, partitions or kitchen furniture and the like, it is advisable

to make these facilities with non-combustible material, otherwise cover them with non-

combustible heat-resistant material, and pay attention to fire prevention regulations.

The appliance should be installed in a well-ventilated area with exhausting facilities, which may

ensure that all burnt gases produced during combustion process are completely exhausted.

The appliance is only applicable to low-pressure gas regulating valve. It may lead to loss and

casualty if other regulating valves are used.

Do not seal the screw on the gas valve with seal welding.

Fire warning: If you smell the gas, please keep away from fire. Do not light up any device or

touch the electronic switch. Do not use any phone in the building either. Close the main gas

valve immediately and call the professional personnel to maintain it. Operation or improperly

maintained will lead to large gas leakage or deflagration easily. The manufacturer will not bear

any responsibility for fire accidents caused by improper operation or maintenance.

FIRE, INJURY or DEATH HAZARD

This equipment must be installed by a qualified installer in accordance with all federal, state and

local codes. Failure to install this equipment properly can result in injury or death.

As continued product improvement is a policy of Vionet, specifications are subject to change.

8830 Siempre Viva Road Suite 100 | San Diego CA 92154 | https://www.vionetequipment.com