3

Sommaire

Safety instructions...................................................................................... 5

General safety instructions..................................................................................... 5

Choice of tool .................................................................................................................... 5

Maintenance and storage ................................................................................................. 5

Safety instructions for the user ......................................................................................... 5

Safety instructions relating to the work area ..................................................................... 6

Prohibited uses ...................................................................................................... 6

Handling and working instructions ......................................................................... 7

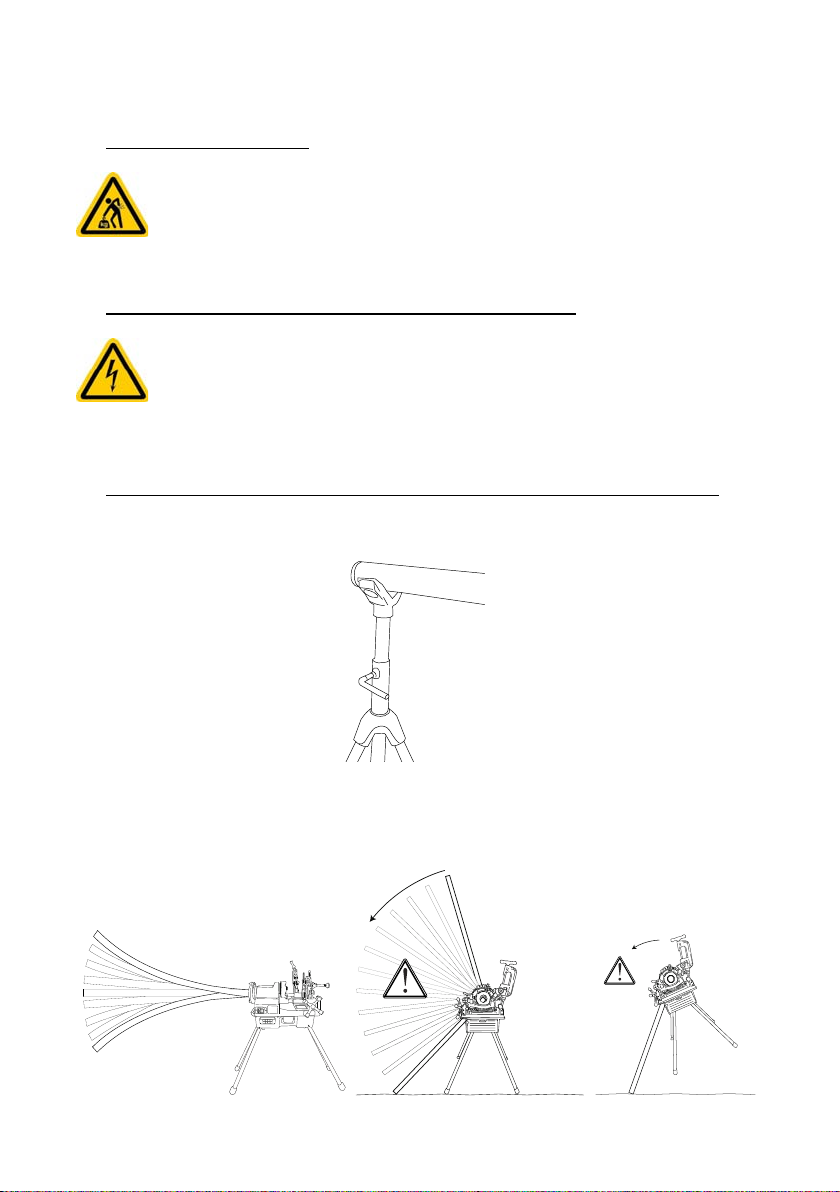

Transporting the machine ................................................................................................. 7

Instructions relating to the machine electrical power supply. ............................................ 7

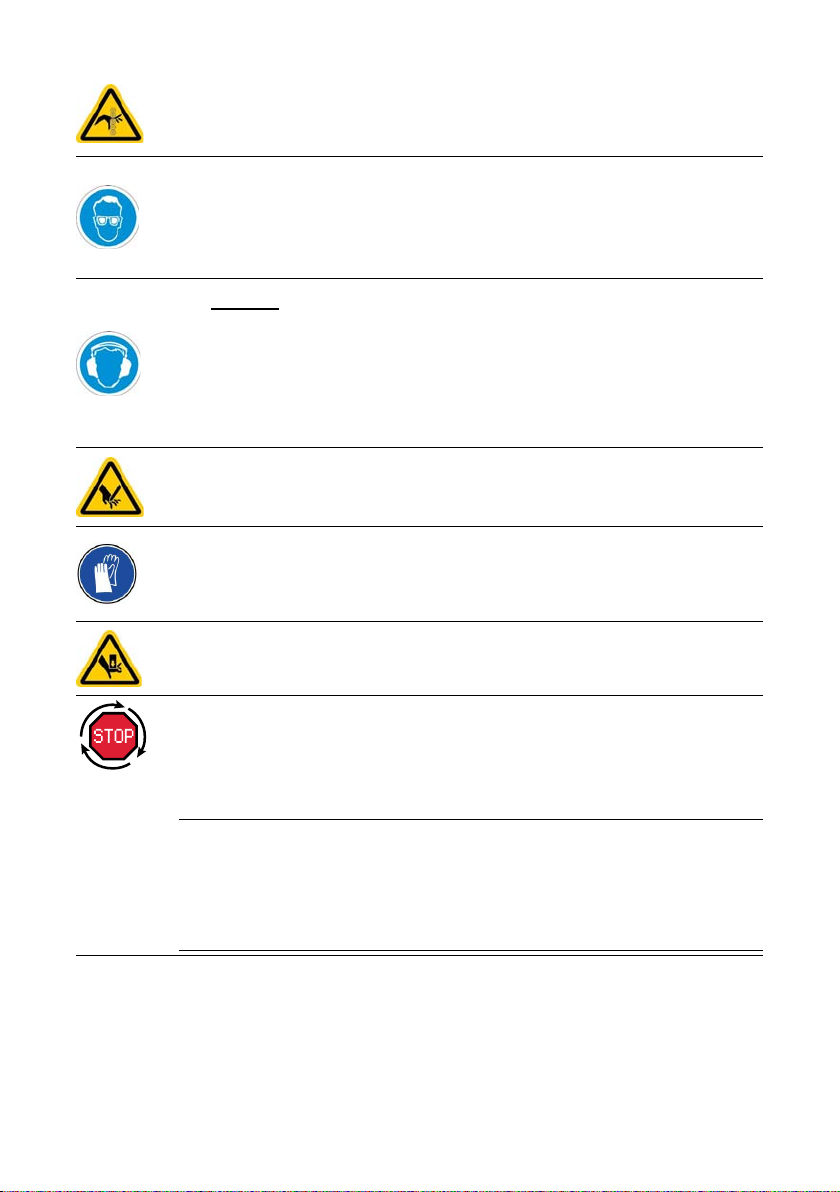

Instructions relating to your protection and the protection of those around you ............... 7

Maintenance instructions .................................................................................................. 9

Storage instructions .......................................................................................................... 10

General description of the 162120 threading machine............................ 11

Basic functions ................................................................................................................. 11

Diameters of tubes which can be threaded ...................................................................... 11

Tubes which can be threaded, cut or reamed .................................................................. 11

Available thread types ...................................................................................................... 12

Setting the length and outside diameter of the thread ...................................................... 12

Option of installing a groover ............................................................................................ 12

General characteristics ..................................................................................................... 13

Moving and setting up the machine .......................................................... 14

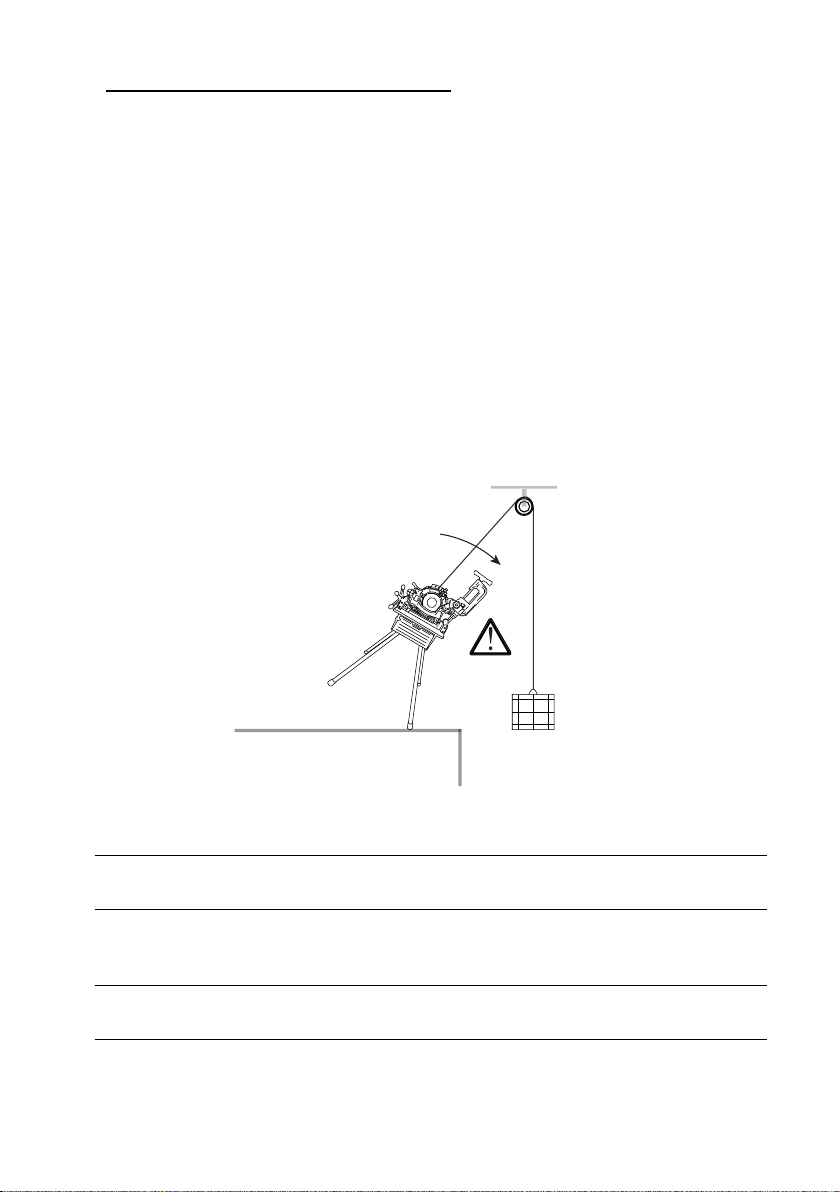

Moving by lifting equipment .............................................................................................. 14

Moving manually ............................................................................................................... 15

Moving using a trolley ....................................................................................................... 15

Slope of the machine ........................................................................................................ 17

Positioning a tube ....................................................................................... 18

Positioning short tubes ..................................................................................................... 18

Cutting a tube .............................................................................................. 19

Reaming a tube............................................................................................ 20

Threading a tube.......................................................................................... 21

Producing a thread ........................................................................................................... 21

Producing double threads on short tubes (nipples or reels) ............................................. 22

Using the 2” die head (Part no. 162151) ................................................................ 25

Installing the head ............................................................................................................ 25

Adjusting the threading diameter ..................................................................................... 26

Adjusting the thread outside diameter .............................................................................. 27

Adjusting the thread length ............................................................................................... 27