LAUNCH KWA-3003DWheelAligner

iii

TableofContents

Introduction...............................................................1-1

Definition................................................................1-1

When Is WheelAlignment Required.......................1-1

Main VehicleAlignment Parameter........................1-1

Toe-in and Toe-out.............................................1-1

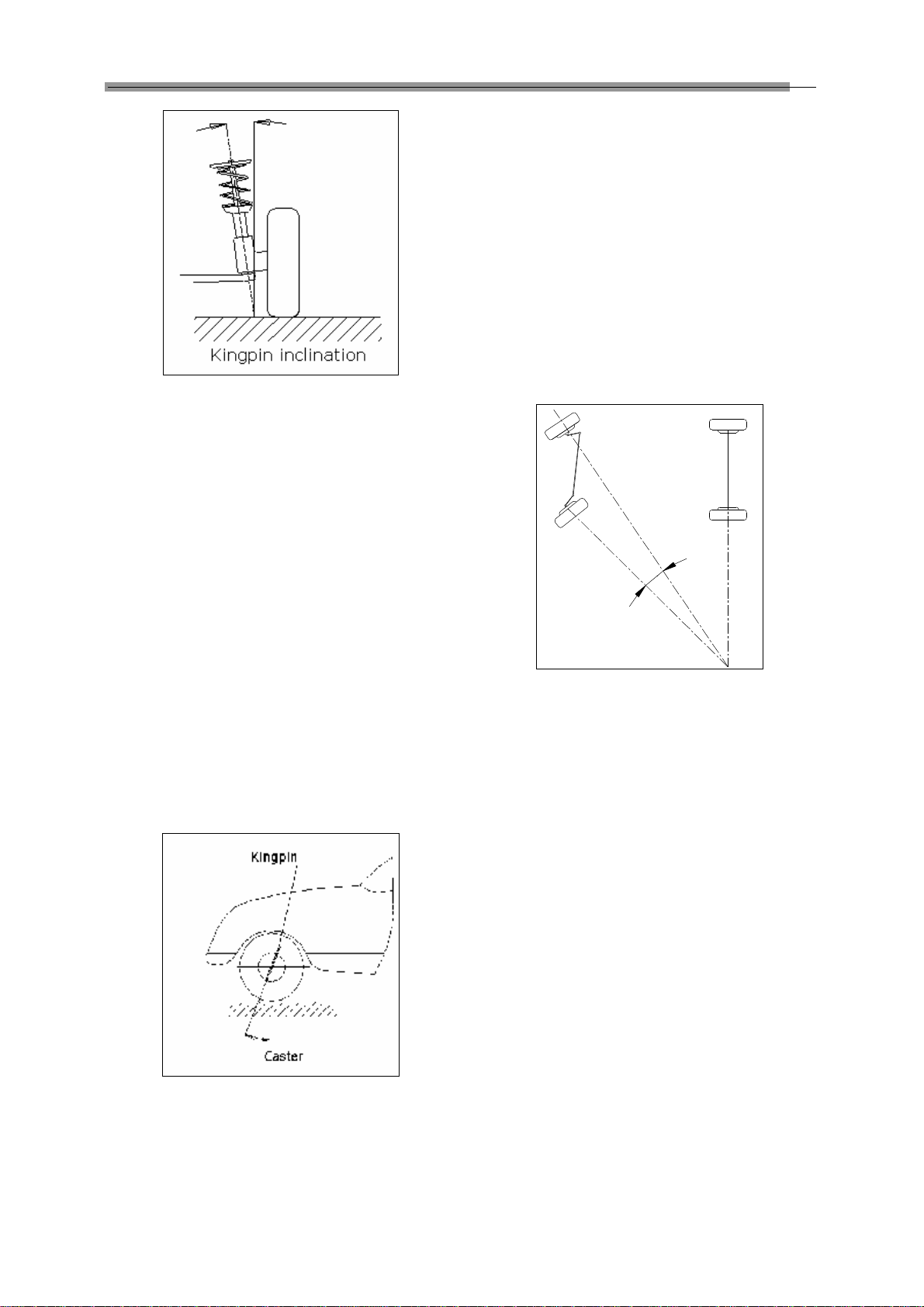

Kingpin Inclination..............................................1-1

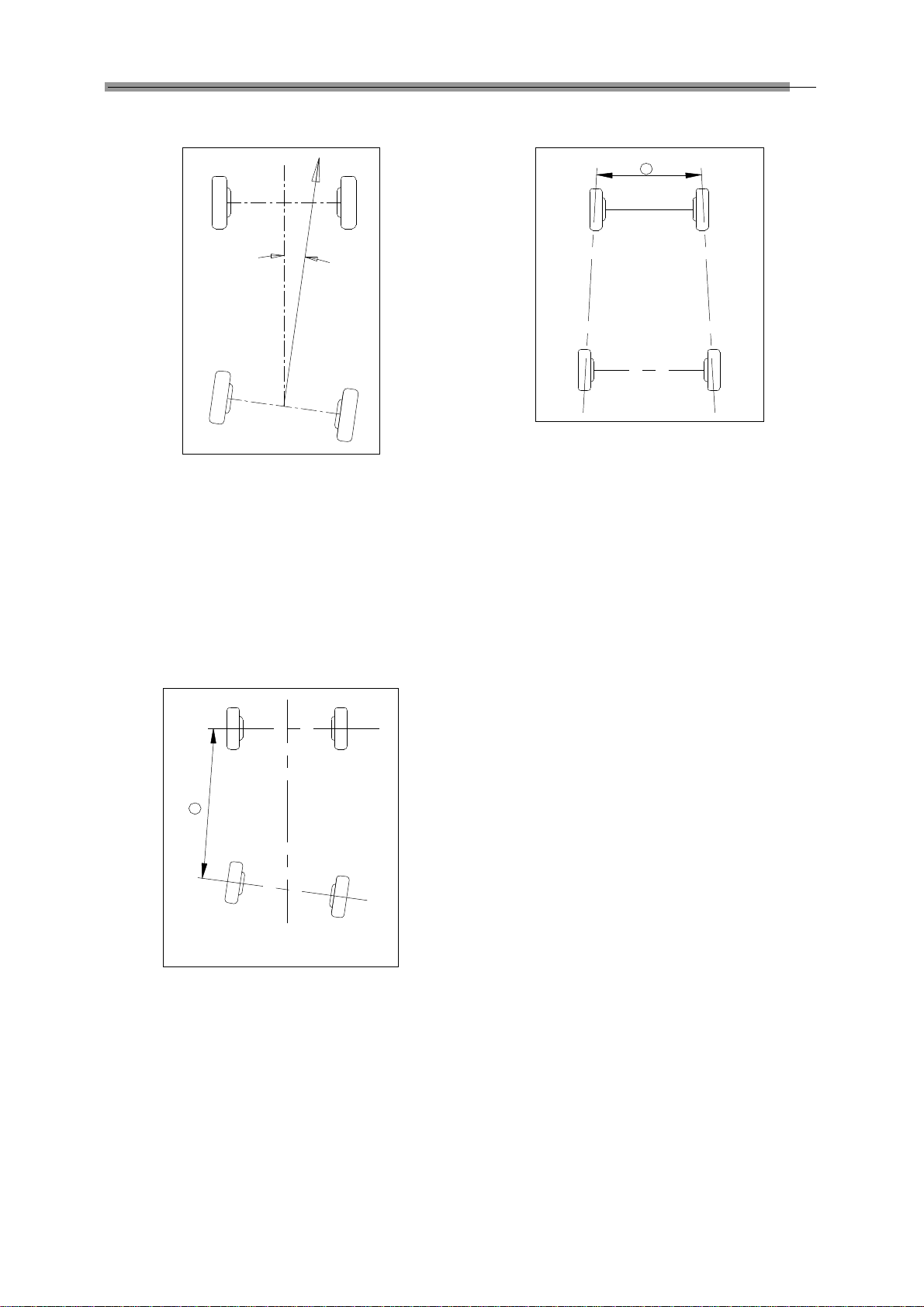

Caster................................................................1-2

Toe-out on Turns................................................1-2

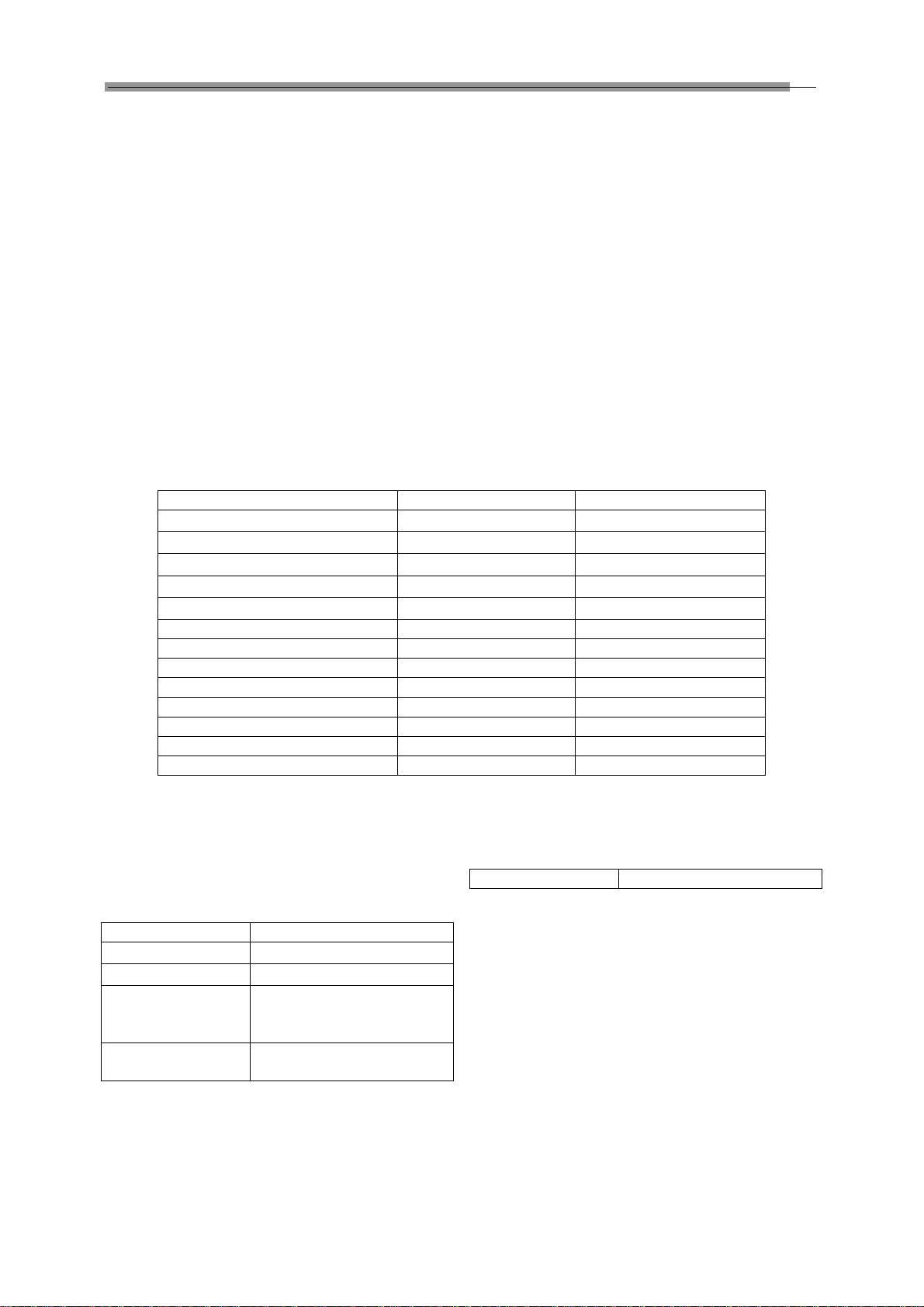

Thrust angle.......................................................1-2

Wheelbase Difference........................................1-3

Tread Difference................................................1-3

Left (right) lateral offset angle............................1-3

Axle offset angle................................................1-3

Delay angle........................................................1-3

Included angle...................................................1-3

Functions and Features.........................................1-4

Specification...........................................................1-4

Requirements on Surroundings..............................1-4

Working Principle...................................................1-4

Structures..................................................................2-1

Overall Structures..................................................2-1

WheelAligner Main Unit.........................................2-1

Cameras and their posts........................................2-1

Wheel Clamps and Targets....................................2-2

Communication cables...........................................2-2

Turntables..............................................................2-2

Steering Wheel Holder...........................................2-2

Brake Pedal Depressor..........................................2-3

Wheel Clamp Tie....................................................2-3

Basic Operation Procedures...................................3-1

Get Vehicle Information..........................................3-1

WheelAlignment Checking....................................3-1

Adjustment.............................................................3-1

Test-drive................................................................3-1

Operation Instructions.............................................4-1

Preparation.............................................................4-1

Descriptions for pushbuttons..................................4-1

Vehicle Standards..................................................4-1

Data Query........................................................4-2

Data Edit............................................................4-3

User Management.............................................4-3

Client Management................................................4-3

AlignmentTest........................................................4-3

Register the Information of Vehicle to be Tested4-3

Test Setting........................................................4-4

StartTest............................................................4-7

System Calibration.............................................4-7

Target Monitoring...............................................4-7

CheckTest Result..............................................4-7

Language Setting...............................................4-7

Help........................................................................4-8

Exit.........................................................................4-8

Frequently Asked Questions (FAQ)........................5-1

Industrial Computer Cannot Start Up, WithoutAny

Prompts..................................................................5-1

Computer Cannot Enter Windows2000..................5-1

Mouse and Keyboard does not Respond...............5-1

Printer does not Respond......................................5-1

KWA-300 3D Program Does Not Run....................5-1

Why the blocking tip box does not appear when you

turn the steering wheel and block the rear target?.5-1

When you turn the steering wheel, the tip box

appears in case of the light path has been blocked,

how to handle it?....................................................5-1

Why does it have obvious difference between left

and right minimum turning radius after alignment?5-1

Maintenance..............................................................6-1

Computer...............................................................6-1

Wheel Clamp and Target........................................6-1

Printer.....................................................................6-1

Posts and signal cables.........................................6-1

Turntables..............................................................6-1