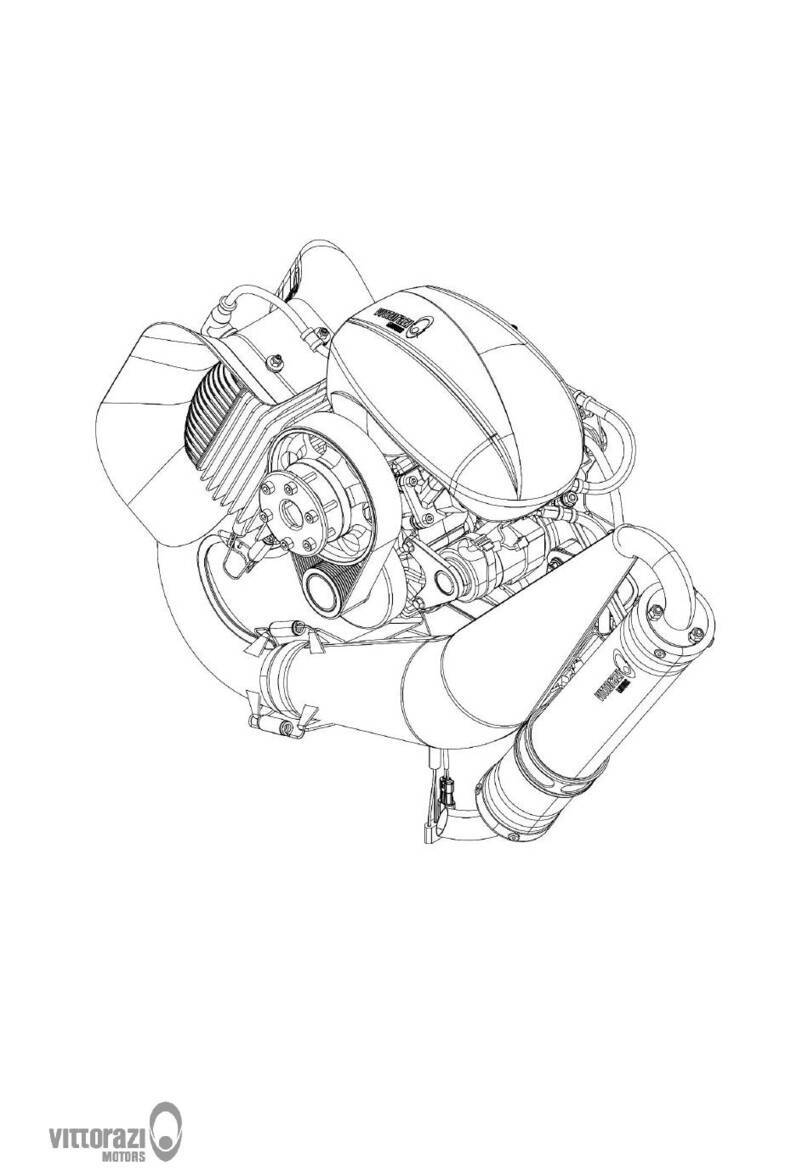

Vittorazi Motors Moster 185 Factory R User manual

MOSTER 185 FACTORY R

Maintenance manual

release V1/2022

valid for MY20-MY22 versions

Moster 185 Factory R - Maintenance manual - V1 2

Moster 185 Factory R - Maintenance manual - V1 3

Contents

1Introduction 6

2Be careful! Read it completely 8

3Maintenance 10

3.1 Maintenance schedule 11

3.2 Spark plug 15

3.2.1 Spark plug disassembly 15

3.2.2 Spark plug maintenance 15

3.2.3 Spark plug assembly 16

3.3 Airbox 17

3.3.1 Airbox disassembly 17

3.3.2 Airbox check 19

3.3.3 Airbox assembly 21

3.4 Carburettor 23

3.4.1 Carburettor disassembly 23

3.4.2 Carburettor check 26

3.4.3 Carburettor assembly 27

3.5 Reed valve 30

3.5.1 Reed valve disassembly 30

3.5.2 Reed valve check 32

3.5.3 Reed valve assembly 33

3.6 Gaskets 35

3.7 Exhaust system 36

3.7.1 Manifold, exhaust bushing disassembly 36

3.7.2 Manifold, exhaust bushing check 38

3.7.3 Manifold, exhaust bushing assembly 39

3.7.4 Silencer disassembly 42

3.7.5 Silencer check 45

3.7.6 Silencer assembly 46

3.8 Rubber mountings 49

Moster 185 Factory R - Maintenance manual - V1 4

3.8.1 Rubber mountings disassembly 49

3.8.2 Rubber mountings check 54

3.8.3 Rubber mountings assembly 54

3.9 Pull starter system 59

3.9.1 Pull starter system disassembly 59

3.9.2 Pull starter system maintenance 62

3.9.3 Pull starter system assembly 64

3.10 Flywheel, coil 68

3.10.1 Flywheel, coil disassembly 68

3.13.2 Flywheel, coil maintenance 71

3.13.3 Flywheel, coil assembly 71

3.11 Transmission 74

3.11.1 Belt removal 75

3.11.2 Belt disassembly 76

3.11.3 Bell, clutch disassembly 78

3.11.4 Transmission maintenance 82

3.11.5 Bell, clutch assembly 86

3.11.6 Pulley assembly 90

3.11.7 Belt insertion 93

3.11.8 Belt tensioning 95

3.12 Piston, cylinder, head 96

3.13.1 Piston, cylinder, head disassembly 96

3.12.1 Piston, cylinder, head disassembly 97

3.12.2 Piston, cylinder, head maintenance 99

3.12.3 Piston, cylinder, head assembly 101

3.13 Crankcase 106

3.13.1 Crankcase disassembly 106

3.13.2 Crankcase maintenance 111

3.13.3 Crankcase assembly 114

3.14 Tightening values 122

Moster 185 Factory R - Maintenance manual - V1 5

Moster 185 Factory R - Maintenance manual - V1 6

1Introduction

Congratulations and thanks for being a Vittorazi qualified professional.

This manual is intended as a point of reference for aircraft manufactures, dealers, professional

people dealing with Vittorazi Motors. Please study this professional manual carefully before

starting the maintenance activity. The purpose of this manual is to provide all the necessary

information to the professional in order to allow a proper maintenance of the engine, carried out

autonomously and in total security. The professional manual includes: technical descriptions of

the maintenance phase and reference values.

All the components of Vittorazi Motors are checked and tested in a process of industrial quality

control before the assembling. Then by sampling the complete motors are checked to assure the

functionality of all the parts through a complete test of twenty minutes on the bench. Note that

the reliability, performance and durability of the engine also strongly depend on the correct

maintenance of which you are in charge.

In case you need further explanations, you can contact directly the headquarters of Vittorazi

Motors. Please include in the request, the six-digit serial number that identifies the motor and a

photo of the item in question.

Also take into account the availability of Illustrated Parts Catalogue (IPC), manual updates, service

bulletins, FAQs, other documents in our official website. The video tutorials are available on the

Vittorazi Motors official YouTube channel. Below the links.

IPC, manuals, bulletins, newsletter, warranties, FAQ

https://www.vittorazi.com/en/services/

Vittorazi Official YouTube channel: video and free tutorials available

https://www.youtube.com/user/VITTORAZIMOTORS

Moster 185 Factory R - Maintenance manual - V1 7

Reading tips:

Attention, danger, risk

Any situation or condition which may result in a serious danger

Recommendation, warning, important advice

Moster 185 Factory R - Maintenance manual - V1 8

2Be careful! Read it completely

To fly in total safety, you must read the following recommendations:

•This engine is not certified. This engine does not fulfil airworthiness regulations. The

products are dedicated to non-certified aircraft and flying as a recreational or sporting

activity.

•Final-user must be aware that the engine can stop, break or shut down at any time.

Such an event may require an immediate and forced landing in inadequate,

congested or impervious areas, with the possibility in the end of causing the death of

the pilot or other persons involved.

•The aircraft equipped with this engine must be conducted in full compliance with

rules and regulations in force relating to the activity of leisure and sport aviation, with

regard to the country in which the operations are carried out.

•Vittorazi Motors and its distributors decline any direct or indirect responsibility related

to this kind of activity. By using a new engine, the owner agrees that these terms and

conditions have been accepted at the time of purchase of the product.

•The engine is not covered by any liability insurance. The use of the engine

automatically determines the assumption of all risks and personal liability for personal

injury or damage to third parties resulting from the activity.

•Improper use of the products or improper technical service (in relation to the

specifications contained in the user, installation and maintenance manual) will held

harmless the company from any liability for any damage due to the malfunctioning

and immediately void the warranty of the product. So, do not use the motor if it has

not been properly maintained or if it has not been used correctly over time.

•Vittorazi does not assume any responsibility for those engines that are used with parts

that are not original, not approved, modified or that have suffered an improper use.

Use of spare parts not original and not recognized by Vittorazi, can make the engine

dangerous and will void the warranty.

•Unauthorized modifications to the motor, to the reduction, to the propeller can

invalidate the warranty of the motor and can compromise the reliability of the aircraft

and its safety. In case it is necessary to intervene, we invite you to contact an authorized

dealer Vittorazi.

•Some geographical areas, due to particular weather conditions such as pressure,

temperature and humidity can affect the performance of the engine. Before taking

off, test the engine on the ground and make sure it does not behave abnormally.

Moster 185 Factory R - Maintenance manual - V1 9

•Always start the engine on a flat and clean surface, without stones or sand. During all

phases in which the engine is kept running near the ground (such as heating, take off,

landing) it is necessary to maintain a safe distance from the engine. A good safety

distance is 100 meters in every direction.

The following engine speed limits must be respected to avoid engine failures, to keep the

warranty valid and to have a correct maintenance scheduling according to the Vittorazi

program:

•Do not keep the engine at full revs for more than 60 seconds.

•Do not keep revs higher than 7.000 RPM during long cruising flights or long climbs.

The average power delivered by the engine during a flight should remain below the

indicated threshold. Contact the aircraft manufacturer for further clarification.

The temperature limit of CHT is 220° Celsius. Do not persist above this temperature

threshold, engine overheating and irreversible damage could occur.

The use of an EGT instrument is mandatory. Install the sensor in the prearranged position of

the manifold (thread the hole according to the size of the sensor). The temperature limit of

EGT is 650° Celsius. Do not persist above this temperature threshold, engine overheating

and irreversible damage could occur.

The use of the head cooling shroud in combination with Vittorazi approved propellers is

mandatory in this model to ensure performance and correct engine temperatures.

Moster 185 Factory R - Maintenance manual - V1 10

3Maintenance

To ensure a safe, long-lasting product and to keep the warranty valid, the user must follow a

maintenance schedule as outlined in the manuals and record the service work in the service

booklet (available in the Warranty chapter of the user manual). An hour meter integrated in the

aircraft is required, always working and well installed to the engine.

Any procedure of installation, maintenance and/or repair of the products must be carried out

exclusively with the original Vittorazi Motors parts and tools specified by Vittorazi, in compliance

with the specifications contained in the user, installation and/or maintenance manual of the

products; to ensure maximum safety and performance of the products, the above-mentioned

procedures will be carried out by mechanics with proven experience in the ultralight aviation or

general aviation or with experience gained by Vittorazi Motors professional training courses.

Failure to do so, will held harmless the company from any liability for any damage due to the

malfunctioning and immediately void the warranty of the product.

Maintenance work must be carried out when the engine is cold.

Moster 185 Factory R - Maintenance manual - V1 11

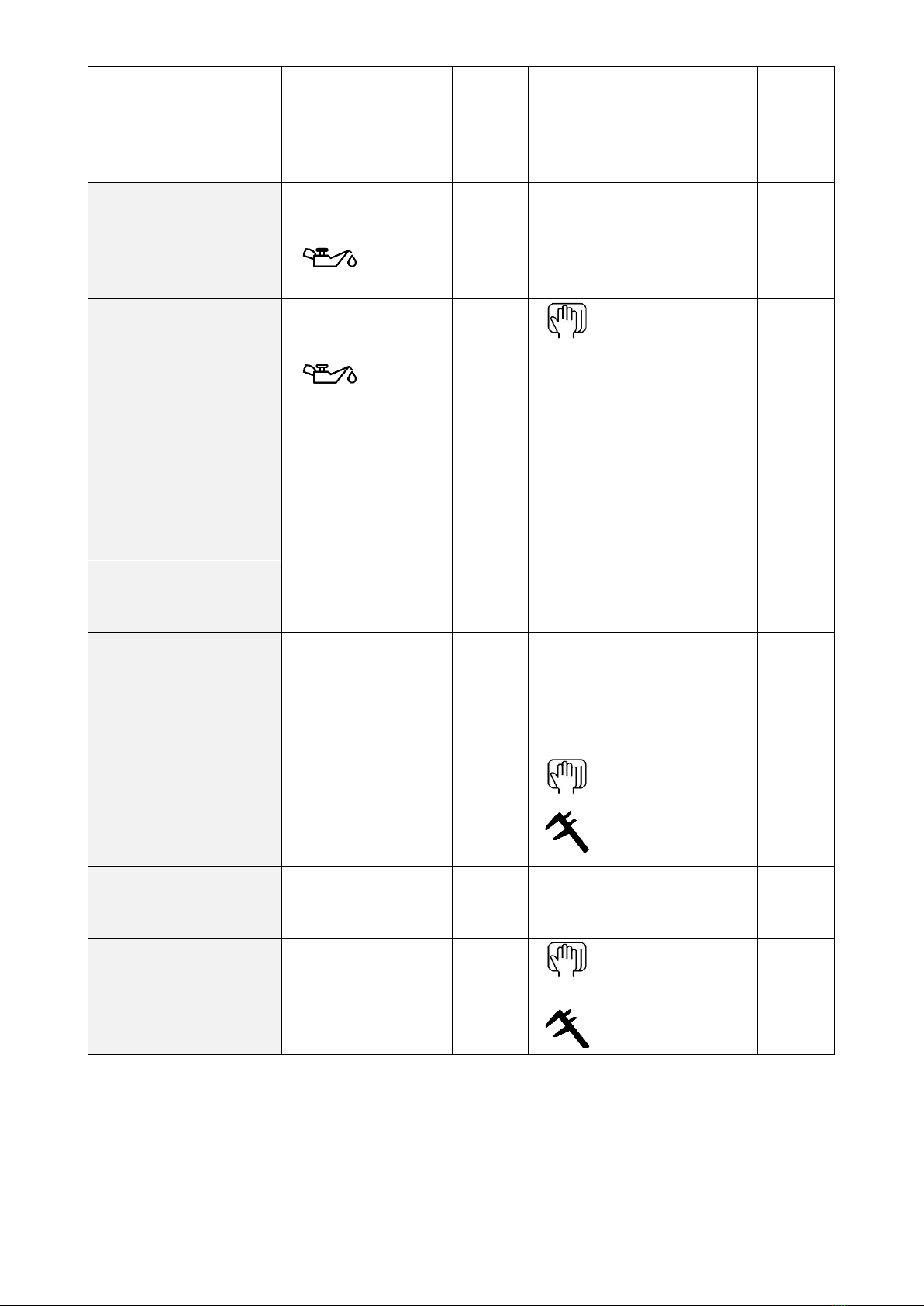

3.1 Maintenance schedule

Refer to the following maintenance indicated time schedule to fly in total safety. Work on the

engine is only allowed to be carried out by experienced mechanic and authorized dealers. These

are prescribed checks at certain interval times to avoid engine problems through preventative

maintenance.

Note:

1) or after a year

2) rope, spring, hooks or a new pull starter system

3) springs

4) each time the component is disassembled

5) head, exhaust port, decompressor hole

6) tensioning

Caption:

Cleaning

Check

Measuring

Replacement

Lubricate with WD-40

Moster 185 Factory R - Maintenance manual - V1 12

Flight hours

Before

each flight

Every 10 h

Every 25 h

Every 50 h

Every 100 h

Every 150 h

Every 200 h

Pre-flight checklist

Screws and nuts

(tightening)

Carburation from

spark plug colour

Spark plug

Spark plug connector

Carburettor

Carburettor

membranes

1)

Airbox Snaplock

Airbox

Airbox sponge and

sleeve

1)

Reed valve petals

Pull starter system

2)

The table follows in the next page

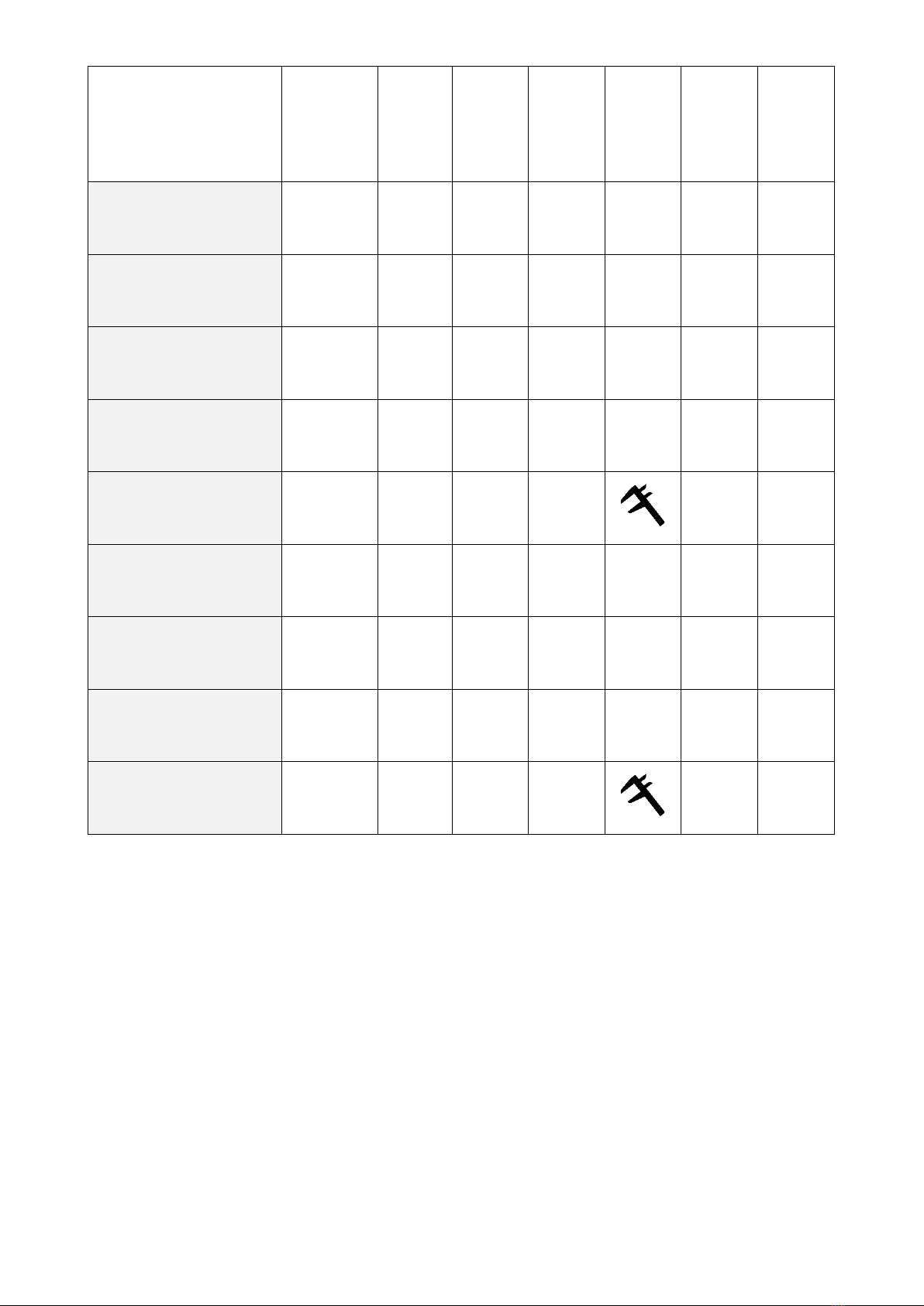

Moster 185 Factory R - Maintenance manual - V1 13

Flight hours

Before

each flight

Every 10 h

Every 25 h

Every 50 h

Every 100 h

Every 150 h

Every 200 h

Kit exhaust bushing

(1𝑠𝑡joint)

Exhaust bushing

(2𝑛𝑑joint)

3)

Exhaust manifold with

springs

Soundproofing

material silencer

Silencer rubber

1)

Gaskets (cylinder,

carburettor, reed

valve, exhaust,

silencer)

4)

Piston

Piston roller bearing

Head and cylinder

5)

The table follows in the next page

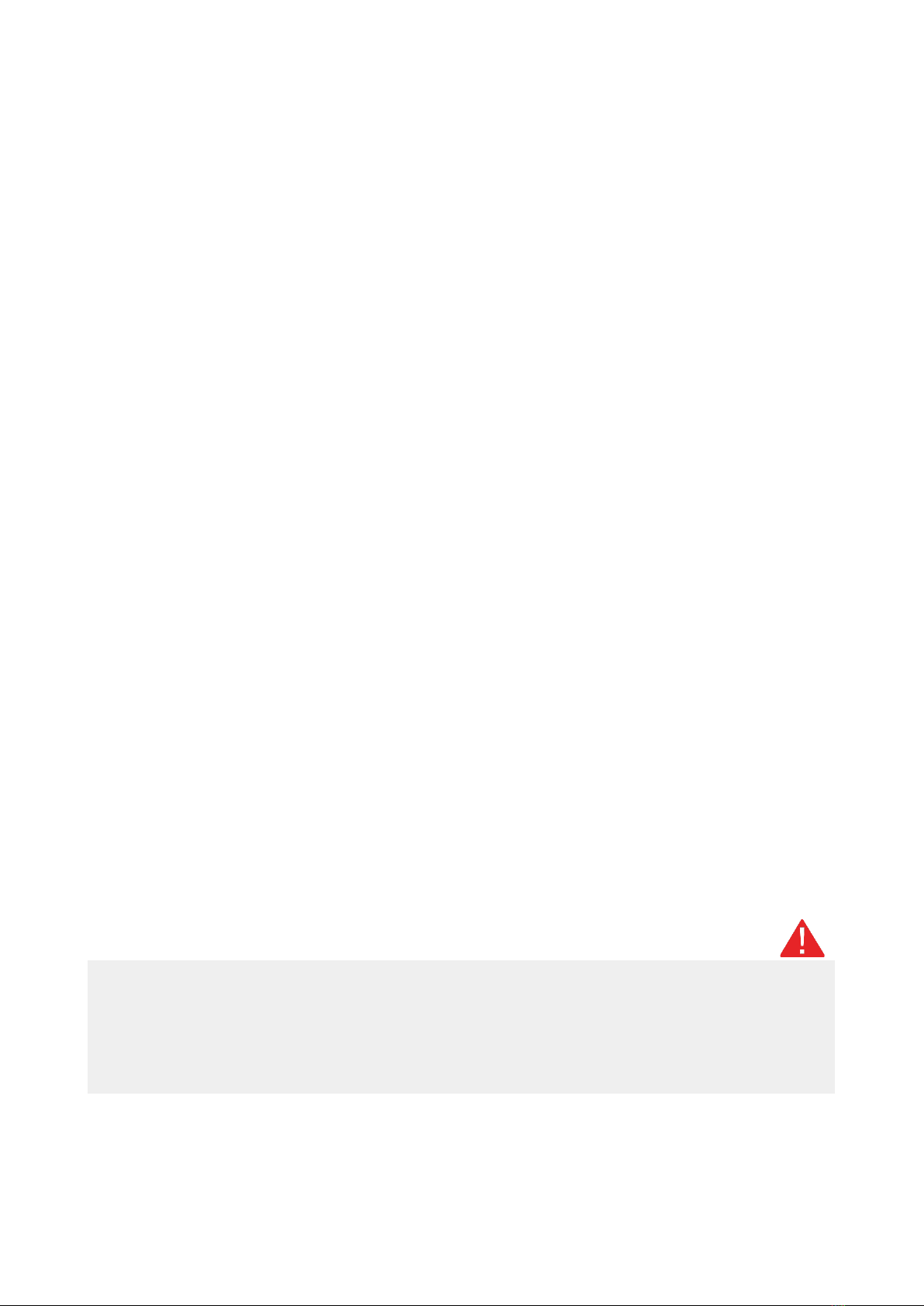

Moster 185 Factory R - Maintenance manual - V1 14

Flight hours

Before

each flight

Every 10 h

Every 25 h

Every 50 h

Every 100 h

Every 150 h

Every 200 h

O-ring head

4)

Rubber mountings

(engine, exhaust)

1)

Oil seal carter case

Crankshaft bearings

Crankshaft

Belt

6)

Reduction

bearings

Centrifugal clutch

Clutch bell

Moster 185 Factory R - Maintenance manual - V1 15

3.2 Spark plug

Components to replace

Spark plug (ACC090).

Special tools

Not required.

Values

Distance between the spark plug electrodes:

0,7 mm (new spark plug)

0,9 mm (worn spark plug limit).

Spark plug: 25 Nm.

3.2.1 Spark plug disassembly

Disconnect the connector and unscrew the spark plug.

3.2.2 Spark plug maintenance

Check the colour of the spark plug: see user manual.

Use a feeler gauge to measure the distance between the spark plug electrodes.

Worn spark plug limit

(mm)

0,9

If the distance between the electrodes is equal to or greater than the indicated limit or if

scheduled maintenance is required, replace the spark plug.

Moster 185 Factory R - Maintenance manual - V1 16

The new spark plug for the engine must be of the same type and rating as the one to be

replaced (NGK BR9EIX).

Check the connector: if it is damaged or the connection to the spark plug is not stable, replace it.

Check the ignition cable: there must be no cuts or cracks, otherwise replace the ignition coil

(including ignition cable).

3.2.3 Spark plug assembly

The distance between the electrodes of the new spark plug must be 0,7 mm, otherwise

adjust.

Screw the spark plug into the head and tighten with the torque shown in the figure.

25 Nm

Moster 185 Factory R - Maintenance manual - V1 17

3.3 Airbox

Components to replace

Time limit

Sleeve with filter (AT093a).

100h or 1 year

Snaplock (MP093d).

25 h

Special tools

Not required.

Values

Clamp screw: 2,5 Nm.

3.3.1 Airbox disassembly

Unhooking the safety strap.

Moster 185 Factory R - Maintenance manual - V1 18

Loosen the screw of the clamp securing the sleeve to the carburettor and remove the airbox.

Fold the sleeve inwards and remove it from the airbox.

Remove the Snaplock.

Moster 185 Factory R - Maintenance manual - V1 19

3.3.2 Airbox check

Clean the sponge with specific filter chemicals. Clean the airbox cavity with compressed air. To

obtain a good seal between the components, degrease the connector of the airbox (1) and the

internal part of the sleeve (2) with a product suitable for cleaning rubber (the sleeve is made up

of a mixture of NBR and PVC).

Check the integrity of the airbox.

Check the sleeve groove.

Moster 185 Factory R - Maintenance manual - V1 20

Check the filter, in particular the bonding with the sleeve and the various parts of the sponge.

Check the Snaplock, in particular the central hole (the photo shows a comparison between a new

component on the left and a worn one on the right).

Connect the Snaplock to the pin on the motor to check that the engagement is stable.

If the above components are damaged, replace them immediately. For routine

maintenance, follow the table.

Use extreme caution when checking, as failure to replace damaged components can lead

to detachment of the airbox and impact with the propeller.

Table of contents

Other Vittorazi Motors Engine manuals

Vittorazi Motors

Vittorazi Motors Moster 185 Classic User manual

Vittorazi Motors

Vittorazi Motors COSMOS 300 User manual

Vittorazi Motors

Vittorazi Motors Moster 185 Plus User manual

Vittorazi Motors

Vittorazi Motors Easy100 User manual

Vittorazi Motors

Vittorazi Motors Easy100 User manual

Vittorazi Motors

Vittorazi Motors MOSTER 185 EFI User manual